Section 8

High Pressure Water System

20479291

2-2012/Rev 04

8-2

The green light on the proximity switch indicates there is power to the switch. The red light

illuminates when the switch is activated. The proximity switches are magnetically activated by

the presence of the metallic surface of the piston. When the switch is activated, it sends a signal

to the PLC to change the flow of the directional control valve and reverse direction.

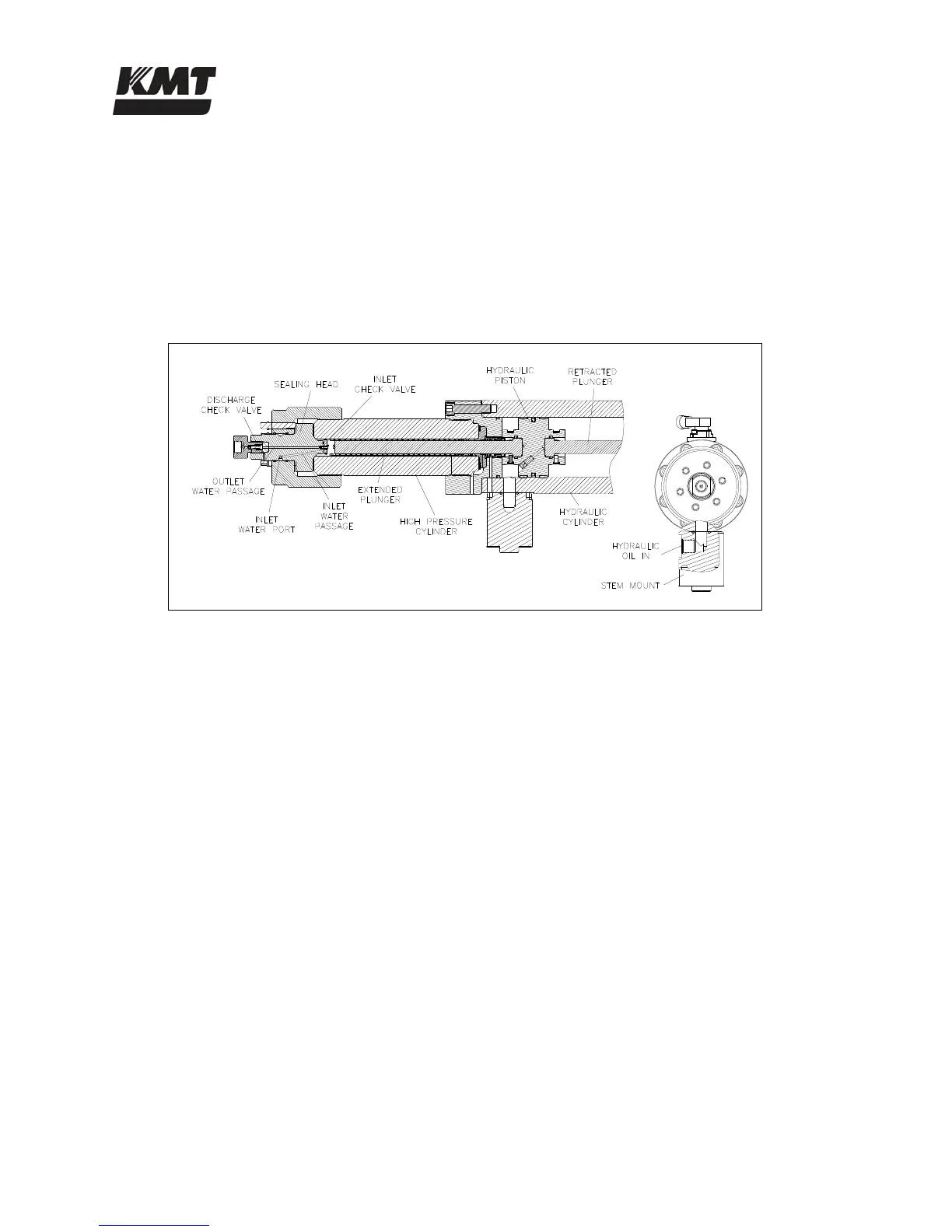

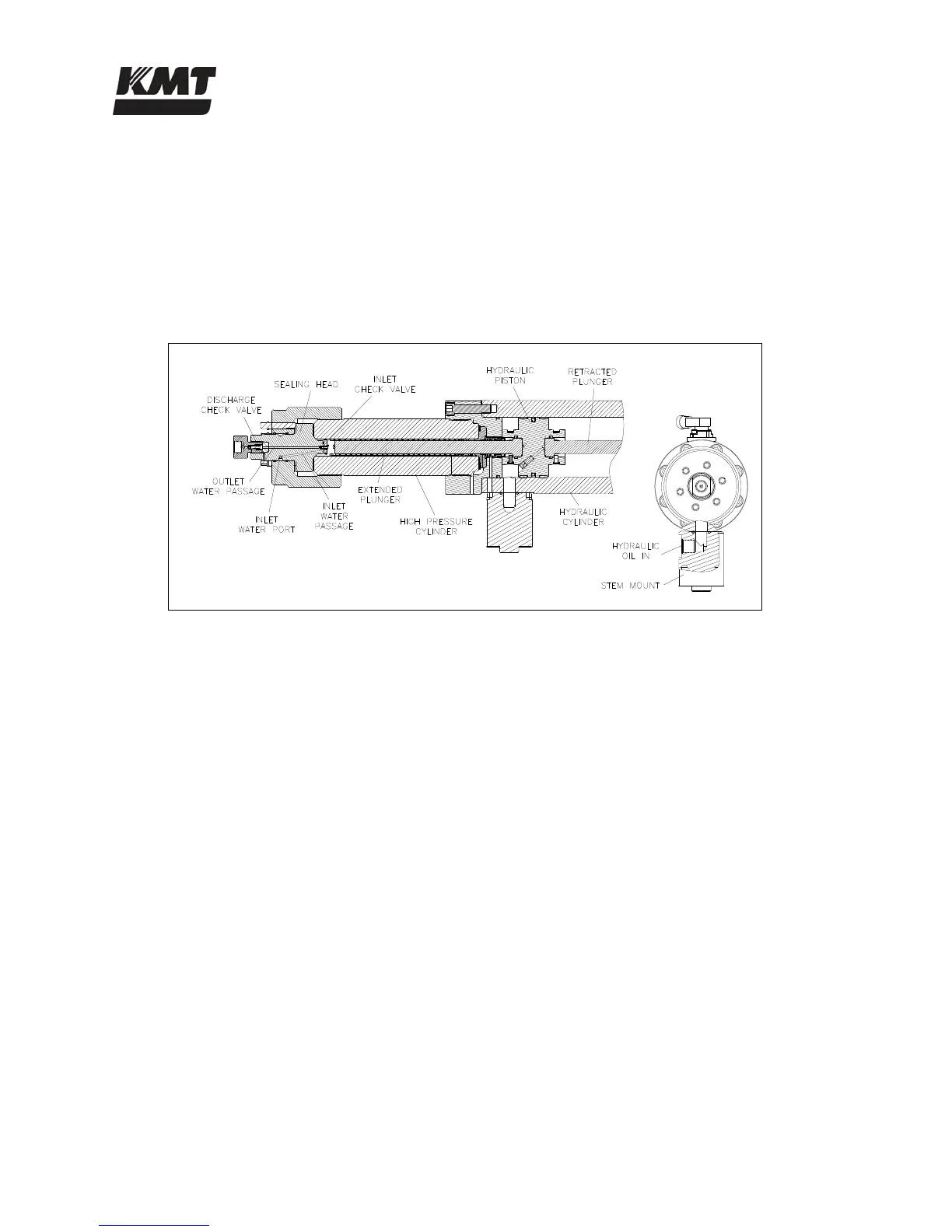

As the pressurized oil pushes the piston in one direction, the plunger on that end extends and

pushes against the water in the high pressure cylinder, increasing the pressure up to 60,000 psi

(4,137 bar). When the piston reverses direction, the plunger retracts and the plunger in the

opposite cylinder extends to deliver the high pressure water.

Figure 8-2: High Pressure Cylinder

Low pressure water is routed through the inlet water ports to the inlet passages in the sealing

heads. When the plunger retracts, the inlet check valve opens to allow water to fill the high

pressure cylinder. When the plunger extends to create high pressure water, the inlet valve closes

to seal the inlet passage and the discharge check valve opens to allow the high pressure water to

exit the cylinder. As the plunger retracts, the discharge check valve closes.

The intensifier is a reciprocating pump. As the piston and plungers move from one side to the

other, high pressure water exits one side of the intensifier as low pressure water fills the opposite

side.

The high pressure water is then routed to the attenuator. The attenuator acts as a shock absorber

to dampen pressure fluctuations and ensure a steady and consistent supply of water. From the

attenuator, the high pressure water exits to the cutting head.

The safety dump valve releases the stored pressure in the intensifier and high pressure delivery

lines. The high pressure dump valve assembly includes a normally open high pressure water

valve and an electrically controlled air valve.

The normally open pneumatic dump valve is held closed by air pressure. When the air supply is

interrupted and exhausted from an emergency stop, the valve opens and allows water to flow

through the valve. Pressure is released in the intensifier and the high pressure water stream exits

through the drain.

Loading...

Loading...