L8-6 Hoist Circuit Component Repair L08031

6. Remove plug (4, Figure 8-10) from end of spool

(7). Remove spring seat (2) and spring (3).

Remove poppet (5) and spool end (6).

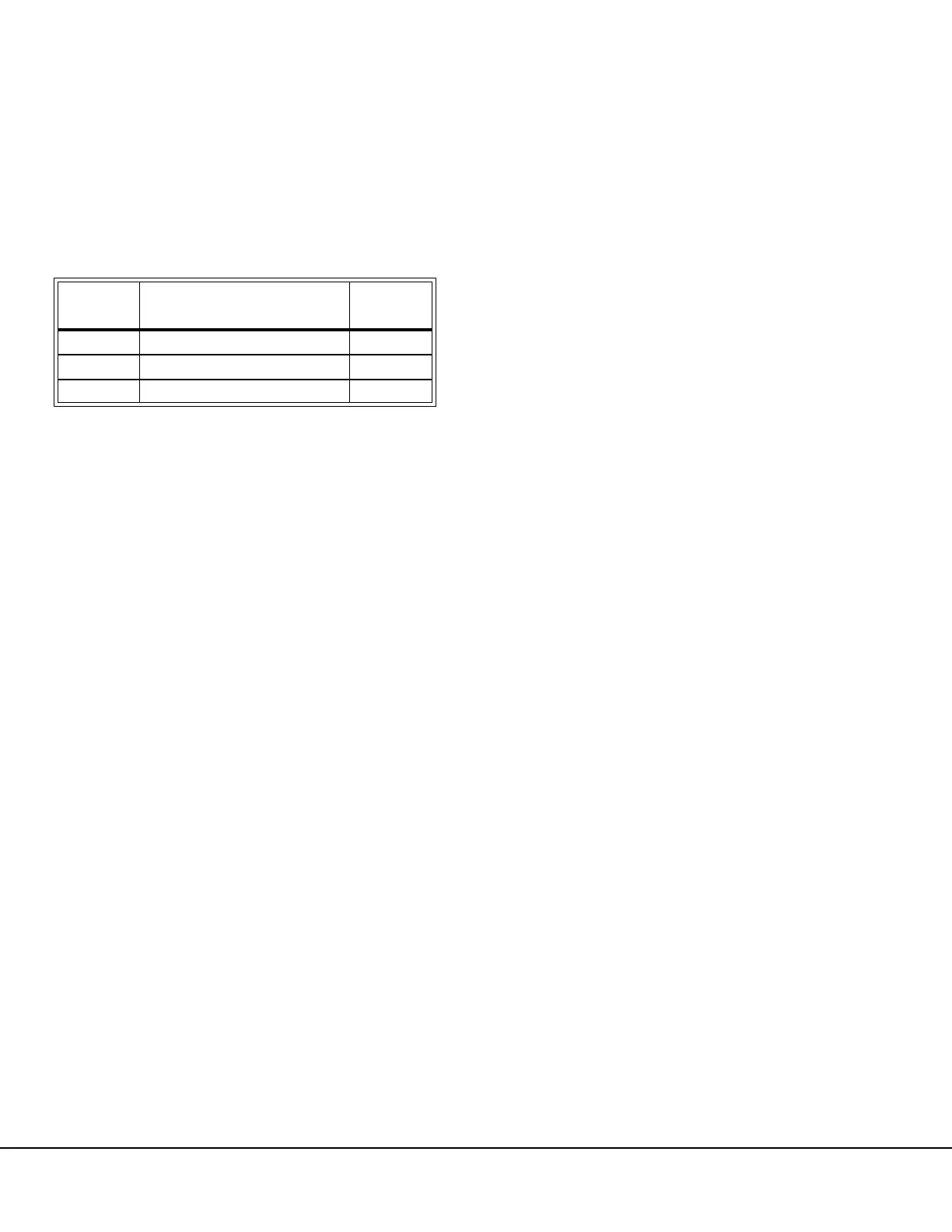

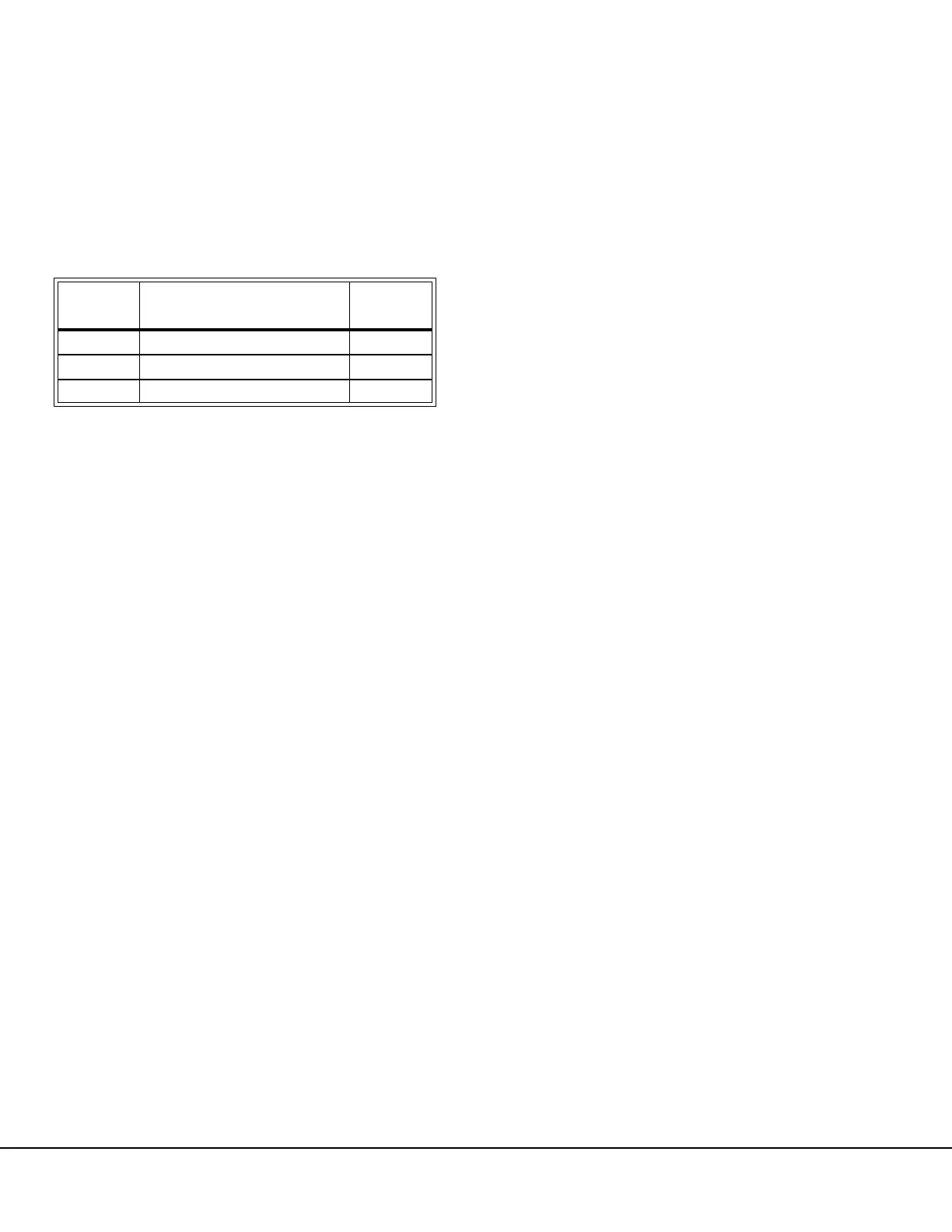

NOTE: Pay special attention to poppets (5, 10 and

25, Figure 8-10) during removal to ensure proper

location during reassembly. Poppets may be

identified with a colored dot; red, white or green. If

poppets are not color coded, use the following chart

for identification:

7. Repeat step 6 for the opposite end of spool (7)

and the top end of spool (23).

8. Remove spool end (22), spring retainer (20) and

spring (21).

9. Remove cover (16), remove O-rings (18 & 19).

Cleaning and Inspection

1. Discard all O-rings and backup rings. Clean all

parts in solvent and blow dry with compressed

air.

2. Inspect all springs for breaks or distortion.

Inspect poppet seating surfaces for nicks or

excessive wear. All seats must be sharp and

free of nicks.

3. Inspect all bores and surfaces of sliding parts for

nicks, scores or excessive wear.

4. Inspect all poppets in their respective bore for fit.

Poppets should move freely without binding

through a complete revolution.

Assembly

1. Lubricate O-rings (18 & 19, Figure 8-10), with

clean hydraulic oil. Install O-rings in spool

housing and install cover (16). Secure cover in

place with capscrews. Tighten capscrews to 60

ft. lbs. (81 N.m) torque.

2. Install spring (3, Figure 8-10) in spool (7). Install

spring seat (2). Apply Loctite

®

to the threads of

spool end (6). Install spool end (6) and tighten

to 25 ft. lbs. (34 N.m) torque. Install poppet (5).

Apply Dri-loc #204 to the threads of plug (4).

Install plug (4) and tighten to 15 ft. lbs. (20

N.m) torque.

NOTE: Poppets 5, 10 and 25 may be color coded

and must be installed in their original location.

3. Repeat step 2 for the opposite end of spool (7).

Make sure spring (8) is blue in color.

4. Lubricate spool assembly (7) and carefully

install in spool housing (15). Make sure the “V”

groove in spool (7) is in the up position, or

toward cover (1).

5. Repeat step 2 for the top end of spool (23). The

bottom end of spool (23) does not contain a

poppet or plug. Install spring (21) which is blue

in color, spring seat (20) and spool end (22).

Apply Loctite to spool end threads. Install spool

end (22) and tighten to 25 ft. lbs. (34 N.m)

torque.

6. Lubricate the assembled spool (23) and install in

spool housing (15). Make sure the “V” groove is

in the up position, or toward cover (1).

NOTE: Spools (7) and (23) are physically

interchangeable. Make sure spool (23) is installed

toward the base port of the spool housing.

7. Install new O-ring and backup ring on restrictor

poppet (1, Figure 8-8). Install restrictor poppet

in housing.

8. Install new O-rings (12 & 13, Figure 8-10).

9. Install new O-ring and backup ring on poppet (1,

Figure 8-7). Make sure the small steel ball is

installed in poppet (1). Install poppet (1) in

cover (3).

10. Install covers (1, Figure 8-10). Secure cover in

place with capscrews. Tighten capscrews to 60

ft. lbs. (81 N.m) torque.

POPPET

COLOR

ORIFICE DIAMETER

DRILL

SIZE

White 0.063 in. (1.6 mm) #52

Green 0.093 in. (2.4 mm) #42

Red 0.110 in. (2.8 mm) #35

Loading...

Loading...