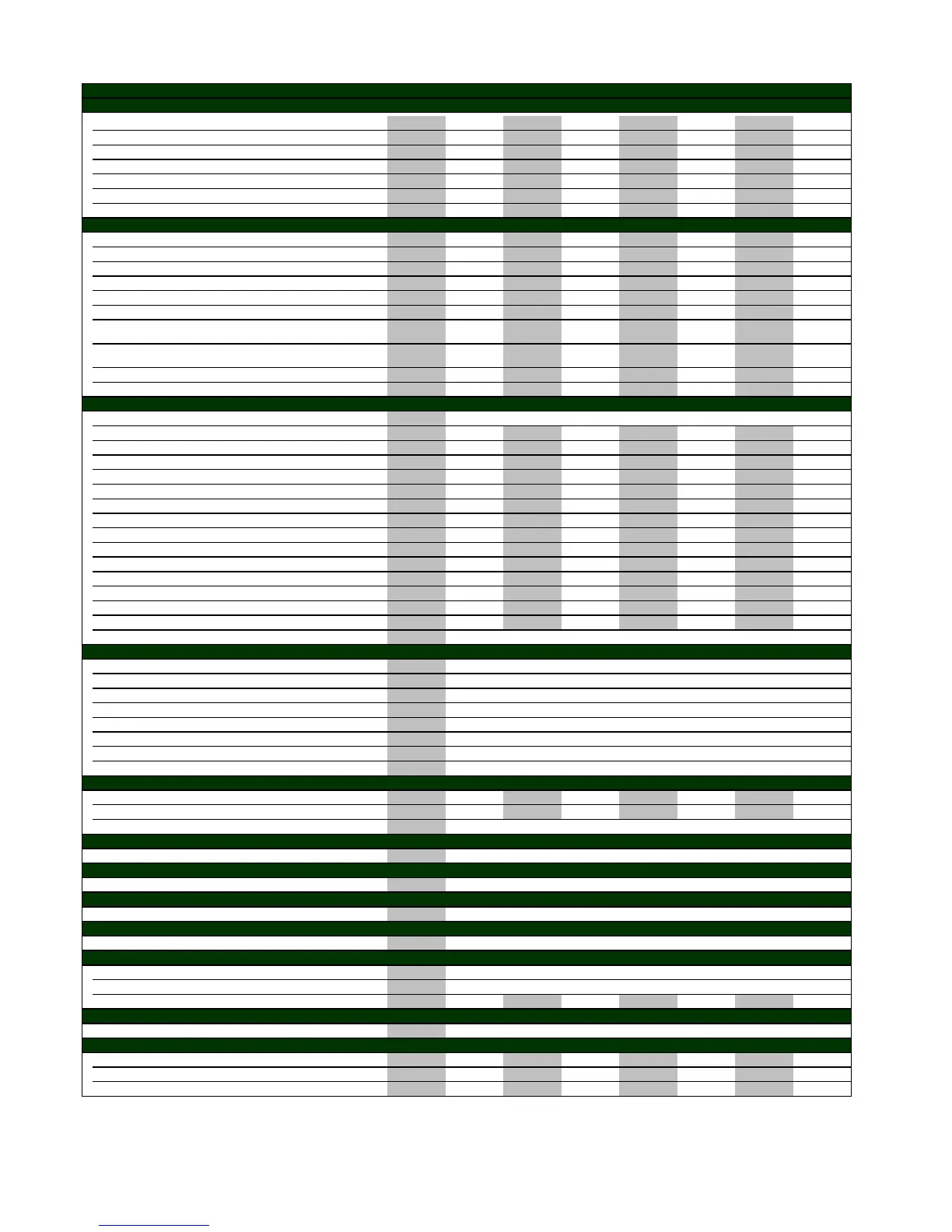

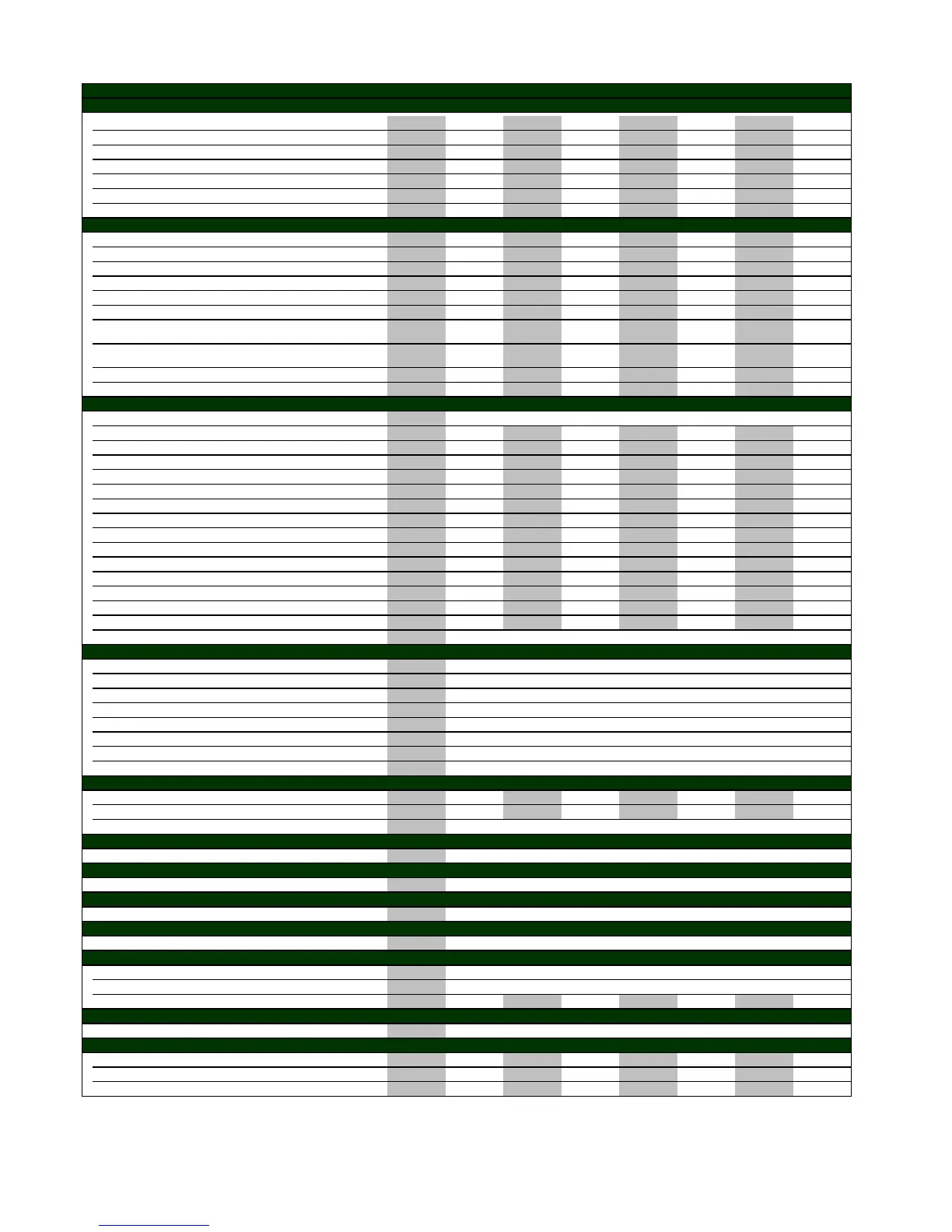

TTD-EF2_EN.xls 07.06.2011 Page 1 of 2

Type

EF2 S / EF2 GS / EF2 V 8 121522253035

Rated power kW 8,0 12,0 15,0 22,0 25,0 30,0 34,9

Partial load kW 2,4 3,5 4,4 6,4 7,3 8,7 10,1

Boiler efficiency at rated power % 94,9 94,0 94,3 95,0 95,2 95,4 95,7

Boiler efficiency at partial load % 88,5 89,4 90,0 91,5 92,4 93,8 95,3

Fuel thermal output at rated load kW 8,4 12,8 15,9 23,2 26,3 31,4 36,5

Fuel thermal output at partial load kW 2,7 4,0 5,0 7,2 8,1 9,6 11

Boiler class according to EN 303-5 3333333

Water side

Water content l 40 40 52 52 78 78 78

Water connection diameter Inches 11115/45/45/4

Water connection diameter DN 25 25 25 25 32 32 32

Water-side resistance at 10 K mbar 5,7 12 34,0 55,9 39,1 62,2 66,2

Water-side resistance at 20 K mbar 1,7 3,5 9,5 15,4 10,8 17,1 18,1

Boiler temperature °C 60–80 60–80 60–80 60–80 60–80 60–80 60–80

Minimum boiler-entry temperature

(for installation of the KWB-supplied two-way valve with servomotor)

°C 10 10 10 10 10 10 10

Minimum boiler-entry temperature

(for installation of an external return-flow boost device)

°C 40 40 40 40 40 40 40

Maximum operating pressure bar 3,5 3,5 3,5 3,5 3,5 3,5 3,5

Test pressure bar 4,6 4,6 4,6 4,6 4,6 4,6 4,6

Flue-gas side

Combustion chamber temperature

Combustion chamber pressure mbar -0,2 -0,2 -0,2 -0,2 -0,2 -0,2 -0,2

Required draft at rated power mbar 0,10 0,10 0,10 0,10 0,10 0,10 0,10

Required draft at partial load mbar 0,06 0,06 0,06 0,06 0,06 0,06 0,06

Suction available Yes Yes Yes Yes Yes Yes Yes

Flue-gas temperature rated power (for chimney calculation) °C 120 120 120 120 120 120 120

Flue-gas temperature partial load (for chimney calculation) °C 90 90 90 90 90 90 90

Flue gas mass flow at rated power kg/h 21,3 32,3 40,2 58,5 66,4 79,4 92,2

Flue gas mass flow at partial load kg/h 6,9 10,2 12,6 18,2 20,5 24,2 27,8

Flue-gas volume at rated power Nm³/h 16,5 24,9 31,1 45,2 51,3 61,4 71,2

Flue-gas volume at partial load Nm³/h 5,3 7,9 9,8 14,1 15,9 18,7 21,5

Smoke-pipe diameter mm 130 130 130 130 150 150 150

Chimney diameter (approx. values) mm 140 140 140 140 160 160 160

Smoke pipe connection height boiler side mm 750 750 870 870 1050 1050 1050

Incline of the smoke-pipe ° ≥ 3° ≥ 3° ≥ 3° ≥ 3° ≥ 3° ≥ 3° ≥ 3°

Chimney design

Fuel

Calorific value

Density

Water content

Ash content

Length

Diameter

Dust proportion before loading

Raw material

Ash

Ash container volume l 28 28 28 28 28 28 28

Ash container filled kg 27 27 27 27 27 27 27

Ash removal system

Electrical System EF2 V W 559,3 559,3 559,3 559,3 577,3 577,3 577,3

Connection

Electrical System EF2 S W 609,3 609,3 609,3 609,3 627,3 627,3 627,3

Connection

Electrical System EF2 GS W 2189,3 2189,3 2189,3 2189,3 2207,3 2207,3 2207,3

Connection

Electrical system EF2 GS with sample probes W 2389,3 2389,3 2389,3 2389,3 2407,3 2407,3 2407,3

Connection

Suction conveyor type EF2 GS

Max. suction length m

Max. suction head m

Contents storage container for type EF2 GS l 42 42 67 67 90 90 90

Storage container type EF2 V

Contents storage container for type EF2 V l

Weights

Boiler weight EF2 V kg 341 341 370 370 416 416 416

Boiler weight EF2 S kg 326 326 352 352 394 394 394

Boiler weight EF2 GS kg 349 349 378 378 424 424 424

107

Yes

900–1100 °C

Moisture-resistant

0.5–3 cm

0.5–0,6 cm

Pellets of pure wood in accordance with ÖNORM M7135 or DIN Plus

17.5 MJ/kg

>650kg/m³

8–10% by weight

<0.5% by weight

230 V

AC

, 50 Hz, 13 A

5

25

<1% by weight

Pure wood, bark proportion < 15% by weight

230 V

AC

, 50 Hz, 13 A

230 V

AC

, 50 Hz, 13 A

230 V

AC

, 50 Hz, 13 A

Loading...

Loading...