2GZ/2G1

1-4-41

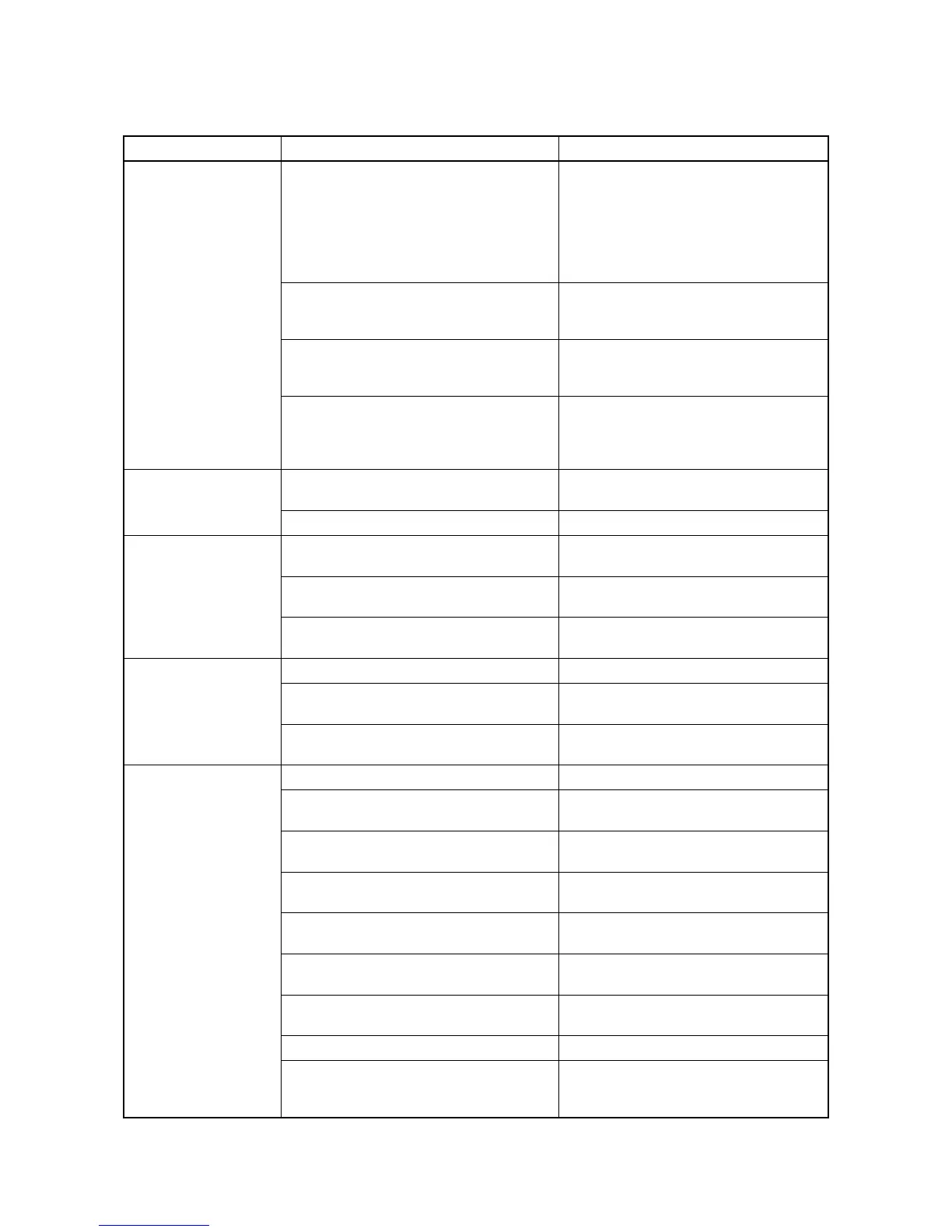

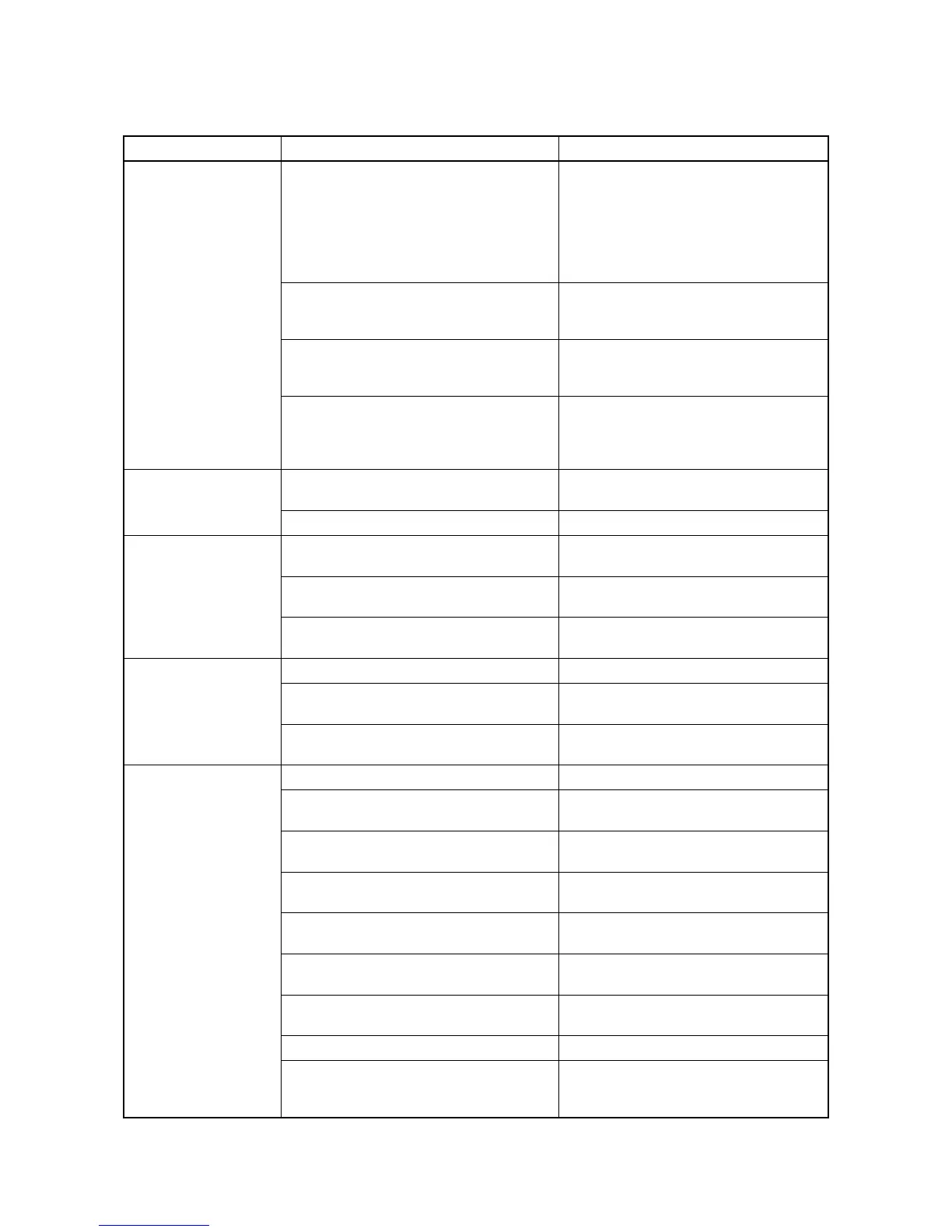

1-4-5 Mechanical problems

Problem Causes/check procedures Corrective measures

(1)

No primary paper feed.

Check if the surfaces of the following rollers or

pulleys are dirty with paper powder: upper/

lower forwarding pulleys, upper/lower paper

feed pulleys, upper/lower separation pulleys,

feed rollers, registration rollers, MP forward-

ing pulley, MP paper feed pulley and MP sep-

aration pulley.

Clean with isopropyl alcohol.

Check if the upper/lower forwarding pulleys,

upper/lower paper feed pulleys or upper/lower

separation pulleys is deformed.

Replace the pulley if it is deformed (see

page 1-5-2).

Check if the MP forwarding pulley, MP paper

feed pulley or MP separation pulley is

deformed.

Replace the pulley if it is deformed (see

page 1-5-4).

Electrical problem with the following clutches:

upper/lower paper feed clutches, feed

clutches 1/2/3, MP paper feed clutch and MP

feed clutch.

See page 1-4-38.

(2)

No secondary paper

feed.

Check if the surfaces of the right and left reg-

istration rollers are dirty with paper powder.

Clean with isopropyl alcohol.

Electrical problem with the registration clutch. See page 1-4-38.

(3)

Skewed paper feed.

Width guide in a cassette installed incorrectly. Check the width guide visually and correct

or replace if necessary.

Deformed width guide in a cassette. Check visually and replace any deformed

guide.

Check if a pressure spring along the paper

conveying path is deformed or out of place.

Repair or replace.

(4)

Multiple sheets of paper

are fed at one time.

Paper is extremely curled. Change the paper.

Check if the upper or lower separation pulley

is worn.

Replace the upper or lower separation pul-

ley if it is worn (see page 1-5-2).

Check if the MP separation pulley is worn. Replace the MP separation pulley if it is

worn (see page 1-5-4).

(5)

Paper jams.

Paper is extremely curled. Change the paper.

Deformed guides along the paper conveying

path.

Check visually and replace any deformed

guides.

Check if the contact between the right and left

registration rollers is correct.

Check visually and remedy if necessary.

Check if the contact between the feed roller

and feed pulley is correct.

Check visually and remedy if necessary.

Check if the press roller is extremely dirty or

deformed.

Clean or replace the press roller.

Check if the contact between the heat roller

and its separation claws is correct.

Repair if any springs are off the separation

claws.

Check if the contact between the eject roller

and pulley is correct.

Check visually and remedy if necessary.

The feedshift solenoid malfunctions. See page 1-4-38.

Check if the duplex feed pulley, upper duplex

feed roller or lower duplex feed roller is

deformed.

Check visually and replace the pulley or

roller if deformed.

Loading...

Loading...