Proline Kryomats

102 Maintenance YAUE0007 / 2/26/2009

9.3.7 Remedying faults

Before you contact the LAUDA Service Temperature Equipment (Ì 9.4), check whether the problem

can be remedied with the following instructions:

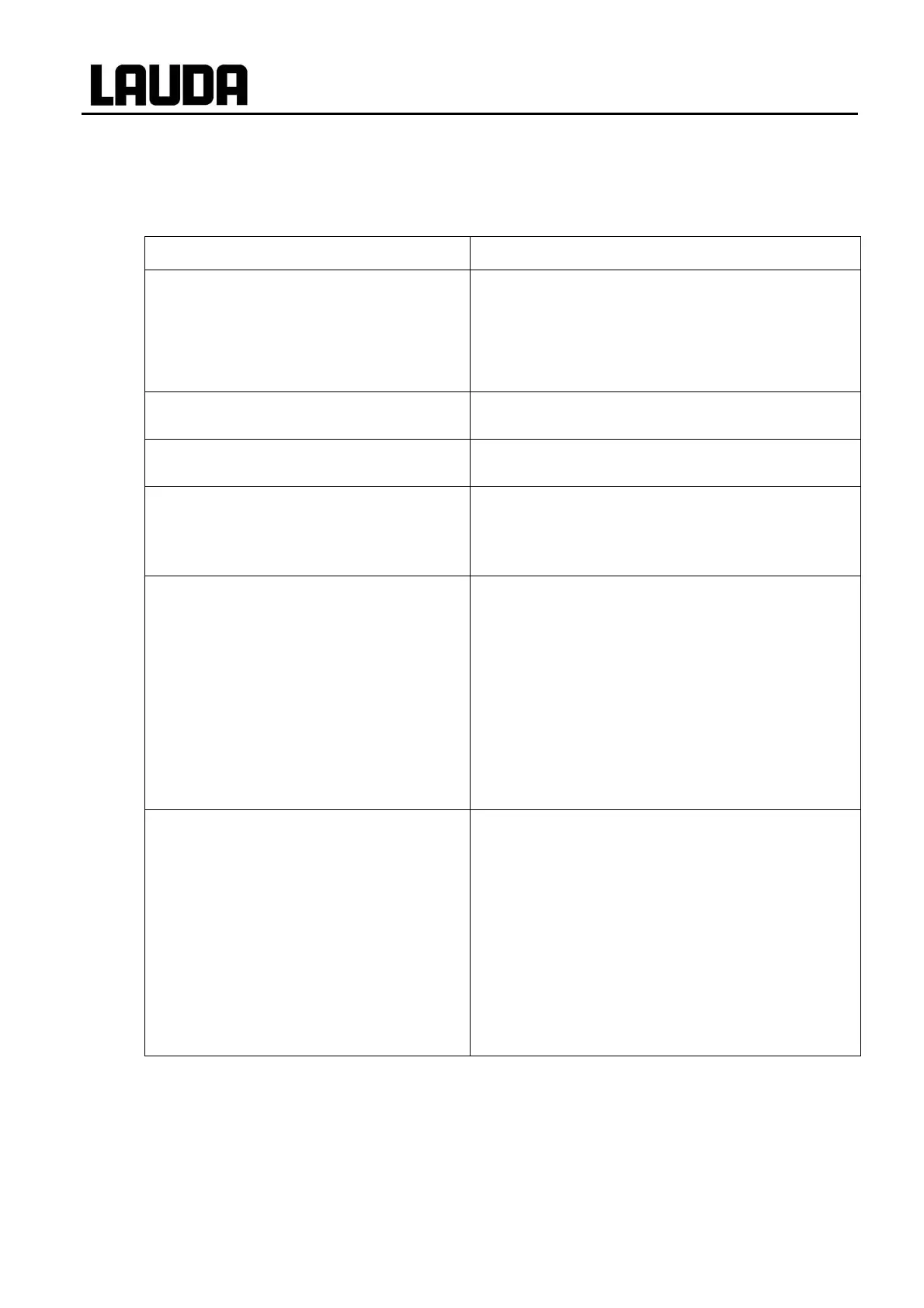

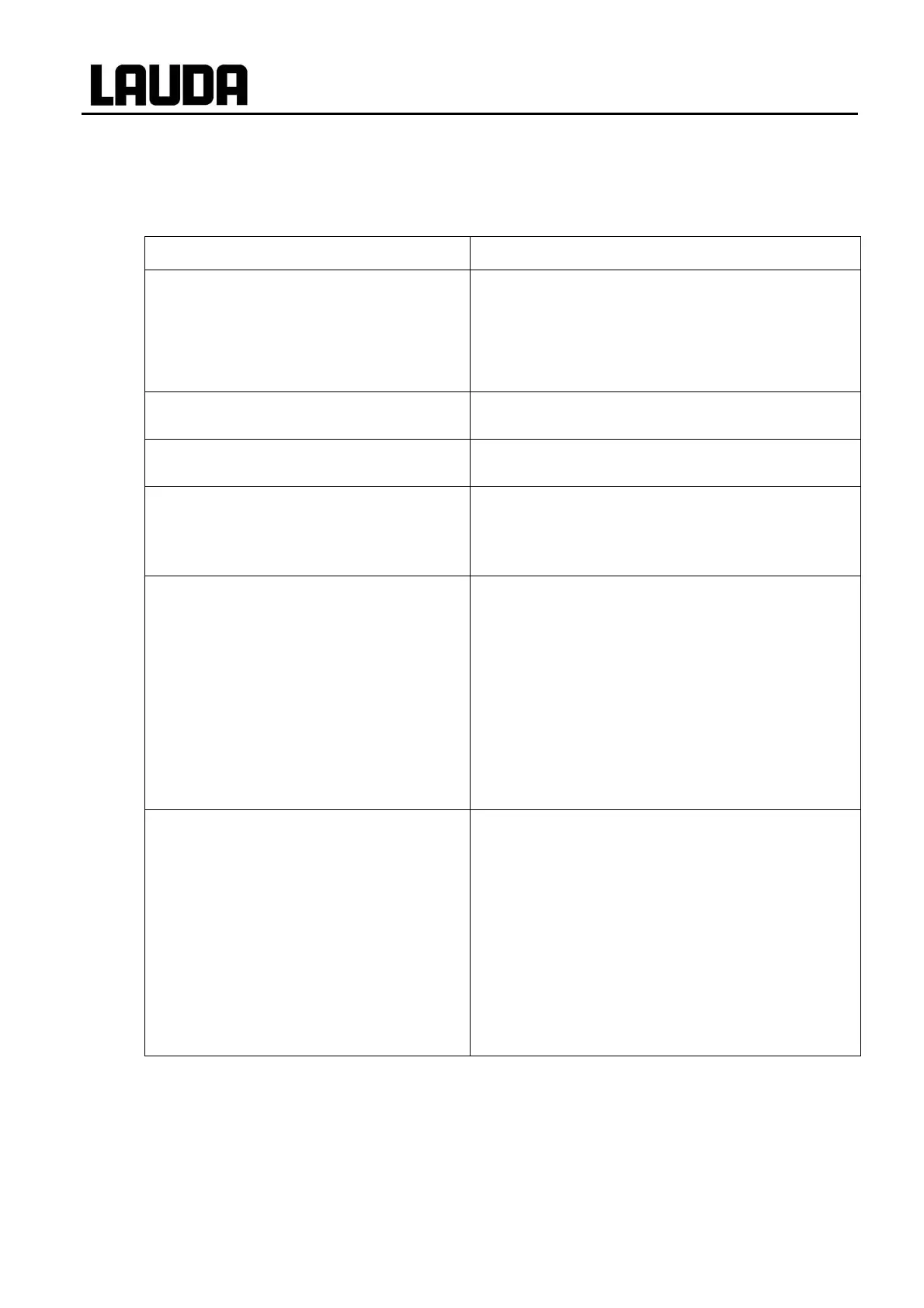

Fault Possible remedy

Device does not cool or only very slowly. 1. The module "Smart Cool" is set to "off" Æ Switch

on "Smart Cool" module Ì 8.2.

2. Dirty condenser Æ Clea

n condenser Ì 9.3.4.

3. Temperatu

re limit Til too high Æ Reduce

temperature limit Til Ì 7.6.2.

Device does not heat up or only very slowly. Temperature limit Tih too low Æ Increase temperature

limit Tih Ì 7.6.2..

The compressors are running although there

is no necessity of cooling.

Regular device function (protectiv function).

Master: Alarm message rDLMO

Command: Overtemperature protection.

Ì 7.12.1.

Wait until the outflow temp

erature ha

s cooled below

the overtemperature cut-off point or set the cut-off

point higher than the outflow temperature.

Master: Warning message VW@pl

0/3

Command: Level very low

(Imminent low level in the bath vessel).

Master: Alarm message

KDTDK

Command: Low level.

(Low level in the bath vessel)

Ì 7.12.2.

1.

Check ho

ses, connections and load for whether a

leaky location is present. Æ As applicable, rectify

the leakage and top up the missing heat carrier

liquid Ì 6.2 and 6.3.

2.

Check the Proline Kryomat

for whether a leaky

location is present. Æ If necessary, contact

LAUDA Service Constant Temperature

Equipment Ì 9.4.

3.

The liquid may drop due to

cooling or degassing.

Æ If necessary, top up the missing heat transfer

liquid Ì 6.2 and 6.3.

Master: Warning message VW@pl

0/2

Command: Level too high

(Imminent excessive level in the bath

vessel).

Master: Alarm message

@K 5

Command: Level too high

(Excessive level in the expansion vessel)

Ì 7.12.4.

1.

Volume expansion of the heat tran

sfer liquid

during heating up.

2. Moisture absorption in the heat transfer liquid.

Loading...

Loading...