MAINTENANCE PROCEDURES

2. Unscrew tensioner lock nut several

turns.

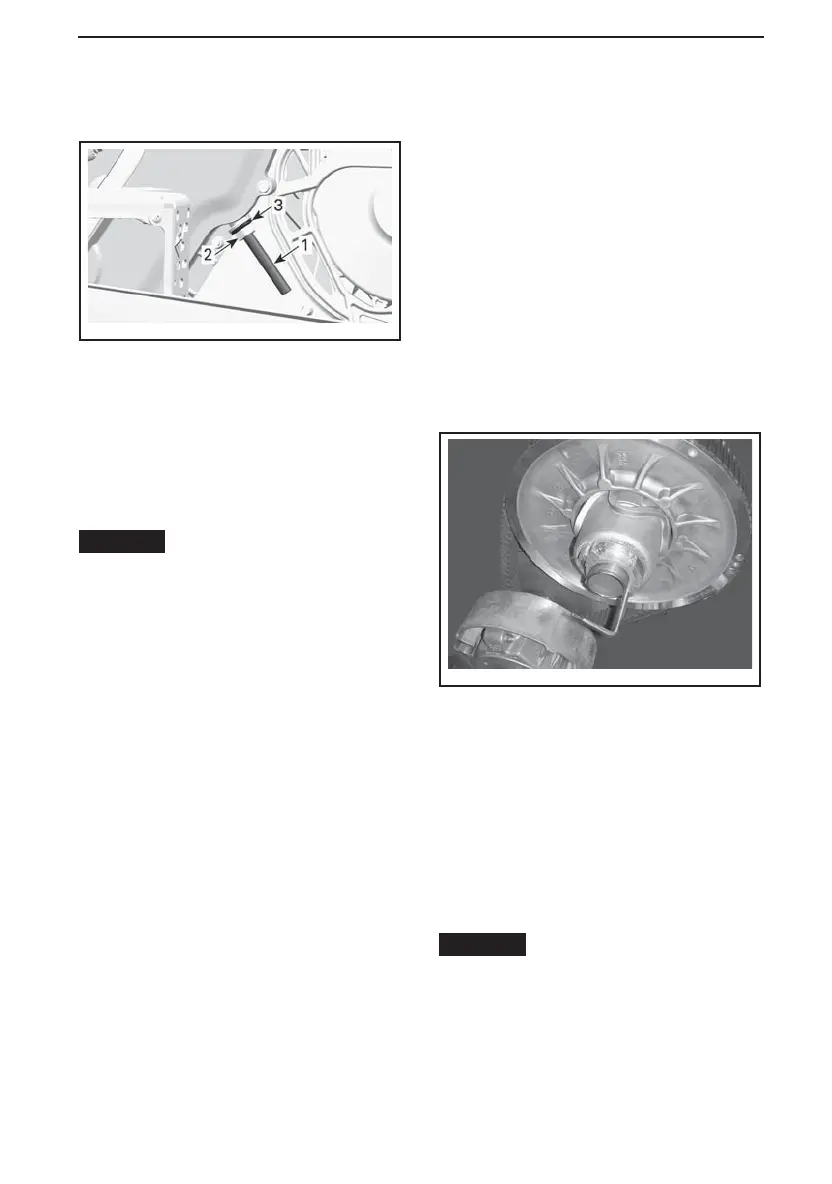

mmr2009-085-002_a

1. Tensioner adjustment screw

2. Lock nut

3. Seal washer

3. Unscrew tensioner adjustment

screw a few turns.

4. Pull seal washer back.

5. Clean adjustment screw threads if

necessary.

NOTICE

Adjustment screw

threads must be clean to obtain an

accurate adjustment.

6. Tighten tensioner adjustment

screw by hand.

NOTE: Turn adjustment screw until

resistance is strong enough that it can

not be turned by hand.

7. Hold tensioner adjustment

screw and tighten lock

nut to 36 N•m ± 3 N•m

(27lbf•ft± 2lbf•ft).

8. Install muffler.

Drive Belt

Drive Belt Inspection

Inspect drive belt for cracks, fraying

or abnormal wear (uneven wear, wear

on one side, missing cogs, cracked

fabric). If a bnormal wea r is noted,

probable cause could be pulley mis-

alignment, excessive RPM with frozen

track, fast starts without warm-up pe-

riod, burred or rusty sheave, oil on drive

belt or distorted spare drive belt. Con-

tact a n authorized Lynx dealer.

Drive Be lt Replacement

Drive Belt Removal

1. Remove tether cord cap from en-

gine cut-off switch.

2. Remove drive belt guard, refer to

CONTROLS, INSTRUMENTS AND

EQUIPMENT

.

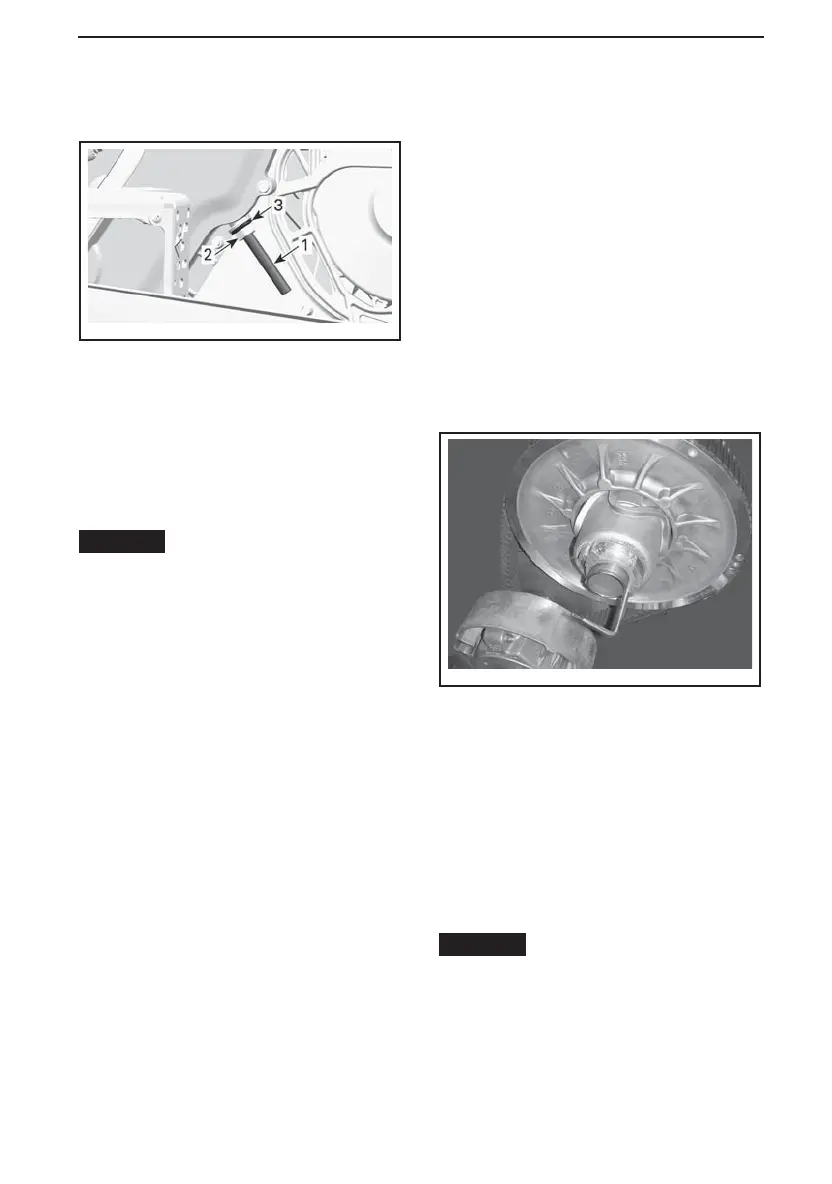

3. Insert the driven pulley expander

provided in the tool kit in the

threaded hole on the adjuster hub

as shown.

mmo2012-005-980

PULLEY EXPANDER INSTALLED ON

ADJUSTER HUB

4. Open the driv en pulley by screwing

the tool in.

5. Remove the belt b y slipping it over

the top of the driven pulley, then

over the drive pulley.

Drive Belt Installation

1. Slip the drive belt over the drive pul-

ley, then over the driven pulley.

NOTICE

Do not force or use tools

to pry the drive belt into place, as

this could c ut or break the cords in

the drive belt.

______________

111

Loading...

Loading...