MAINTENANCE PROCEDURES

There are 6 positions numbered 1 to 6.

The calibration screws have 6 different

settings identified by numbers scribed

on their head.

The actual setting is the screw head

number aligned with the mark on the

pulley.

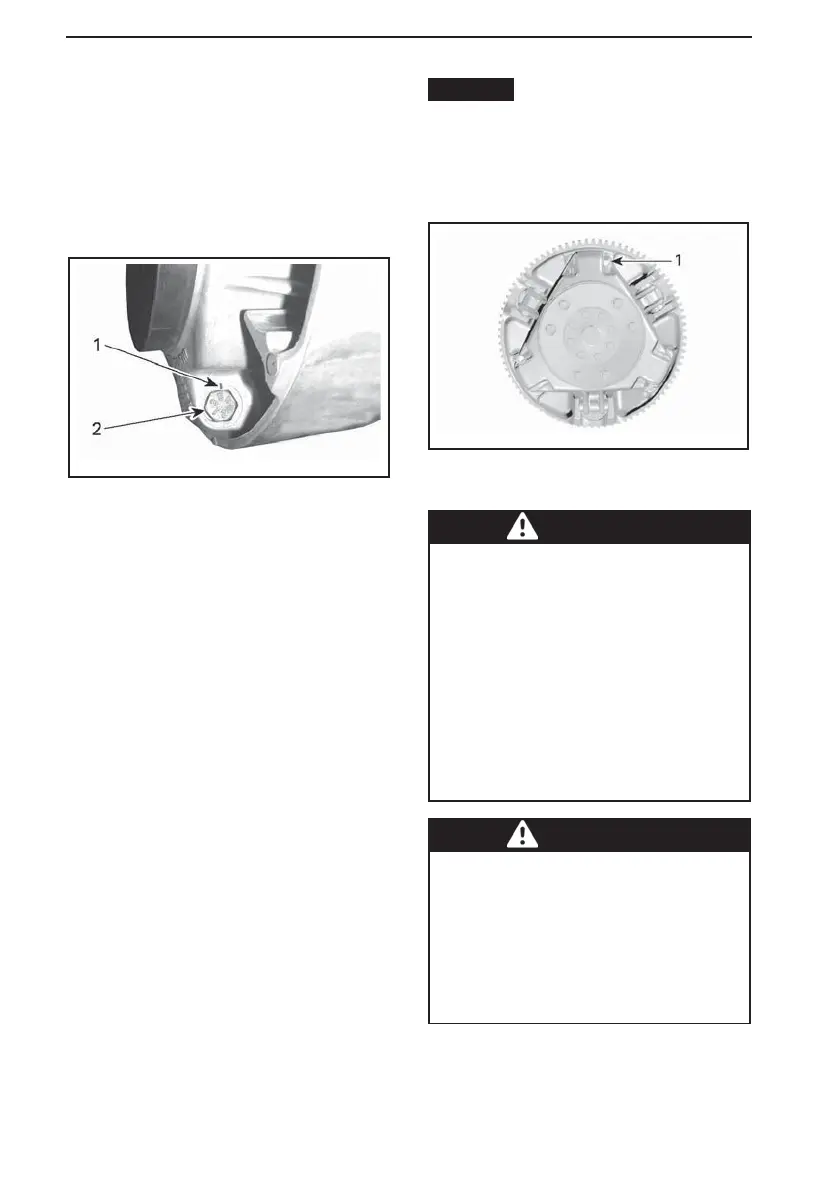

mmo2011-002-101_a

PULLEY SETTING

1. Mark

2. N umber

Each position modifies maximum en-

gine RPM by about 200 RPM .

Lower position numbers decrease en-

gine RPM in steps of 200 RPM and

higher position numbers increase it in

steps of 200 RPM.

Example:

Calibration screws initially set at posi-

tion 4 and changed to position 6 will

increase maximum engine RPM by

400 RPM.

Procedure

Loosen the lock nut just enough to get

the calibration screw head out of the

pulley and rotate to the desired posi-

tion. Do not completely remove the

lock nut.

Set all 3 calibration screws to the same

position.

Tighten lock nuts to 10 N•m ± 2 N•m

(89 lbf•in ±18lbf•in).

NOTICE

Do not completely re-

move calibration screw otherwise

internal washers will fall off. Al-

ways adjust all 3 calibratio n screws

and make sure they are all set to the

same position.

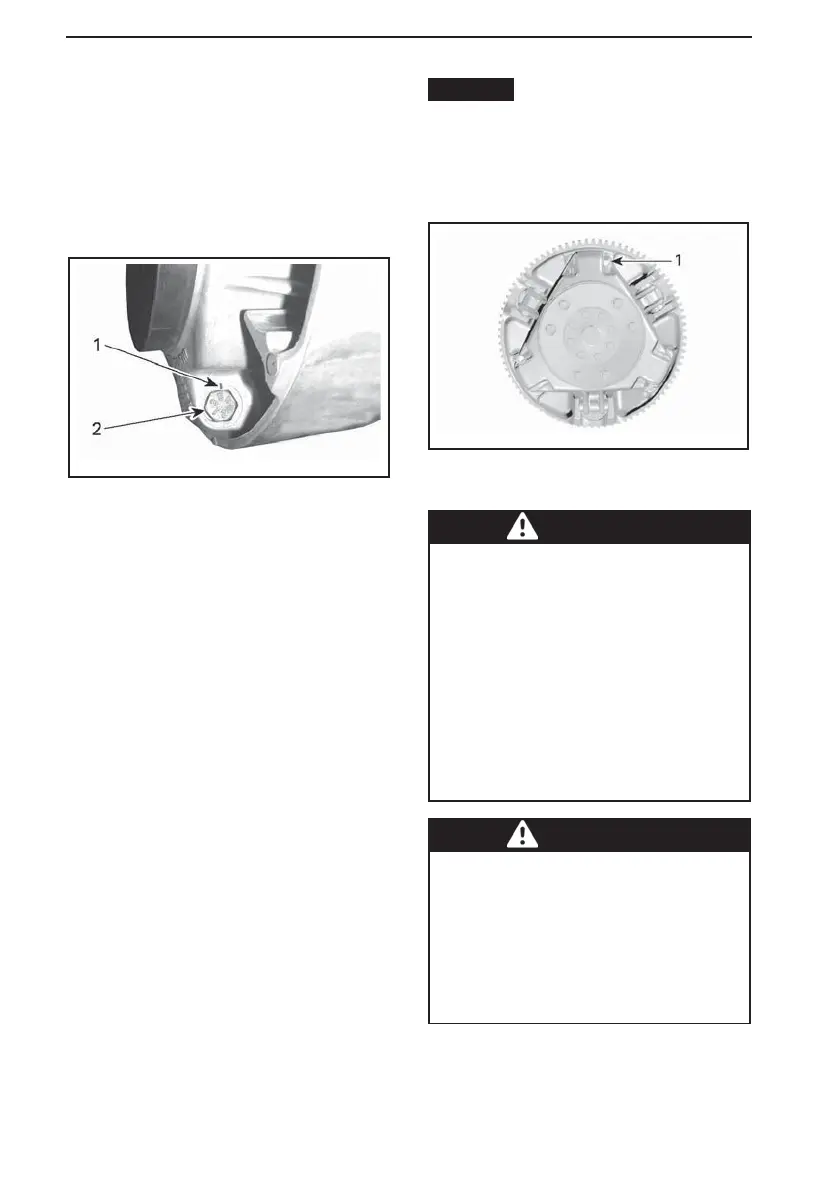

mmo2015-007-303_a

TYPICAL

1. L oosen just enough to permit rotating of

calibrate screw

WARNING

NEVER disassemble or modify the

drive pulley.

Improper assembly or modifica-

tions could cause the pulley to ex-

plode violently under the stress

generated by the high rotational

speed.

See your Lynx dealer to maintain

or service the drive pulley. Im-

proper servicing or maintenance

may affect performance and re-

duce belt life. Always respect

maintenance schedules.

WARNING

NEVER operate engine:

– Without shields and belt guard

securely installed.

– With hood and/or side panels

opened or removed.

NEVER attempt to make adjust-

ments to moving parts while en-

gine is running.

114

______________

Loading...

Loading...