MAINTENANCE PROCEDURES

FICATIONS

at the end of this guide. If

the track tension is too loose, track will

have a tendency to thump.

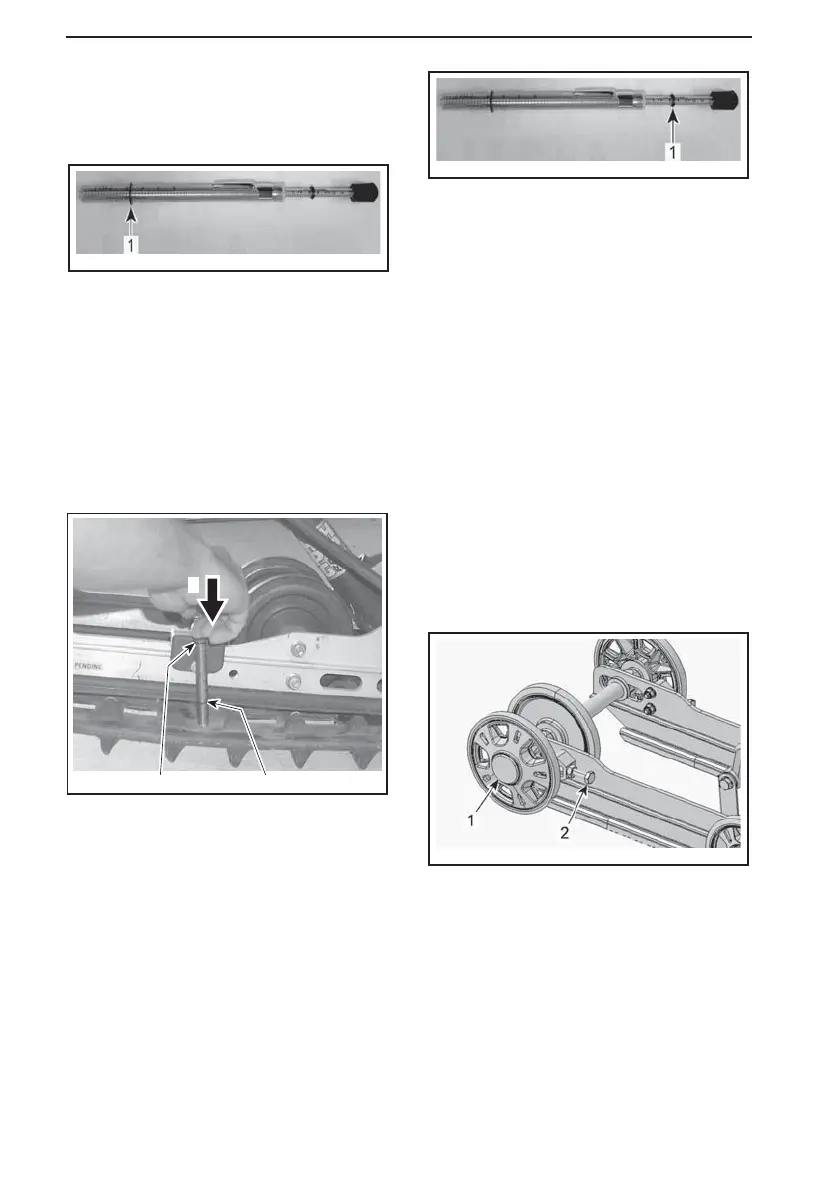

mmr2009-133-003_b

DEFLECTION SETTING

1. Bo ttom O-ring set to specification

6. Place upper O-ring to 0 kgf (0 lbf).

7. Position the tensiometer on track,

halfway between front and rear idler

wheels.

8. Push the tensiometer downwards

until bottom O-ring (deflection set

earlier) be aligned with the bottom

of slider shoe.

3

A32F39A

2

1

TYPICAL

1. Top tool O-ring positioned at 7.3

kg (16 lb)

2. P ush on top portion of tool until it contacts

the to p O-ring

3. Measured track deflection (See

specifications section to find your

model track deflection)

9. Read load recorded by the upper

O-ring on the tensiometer.

mmr2009-133-003_a

LOAD READING

1. U pper O-ring

10. Load reading must be as per the

following table / see

SPECIFICA-

TIONS

at the end of this guide.

11. If load reading is not in accordance

with the specification, adjust track

tension. Refer to

TRACK TEN-

SION ADJUSTM ENT

.

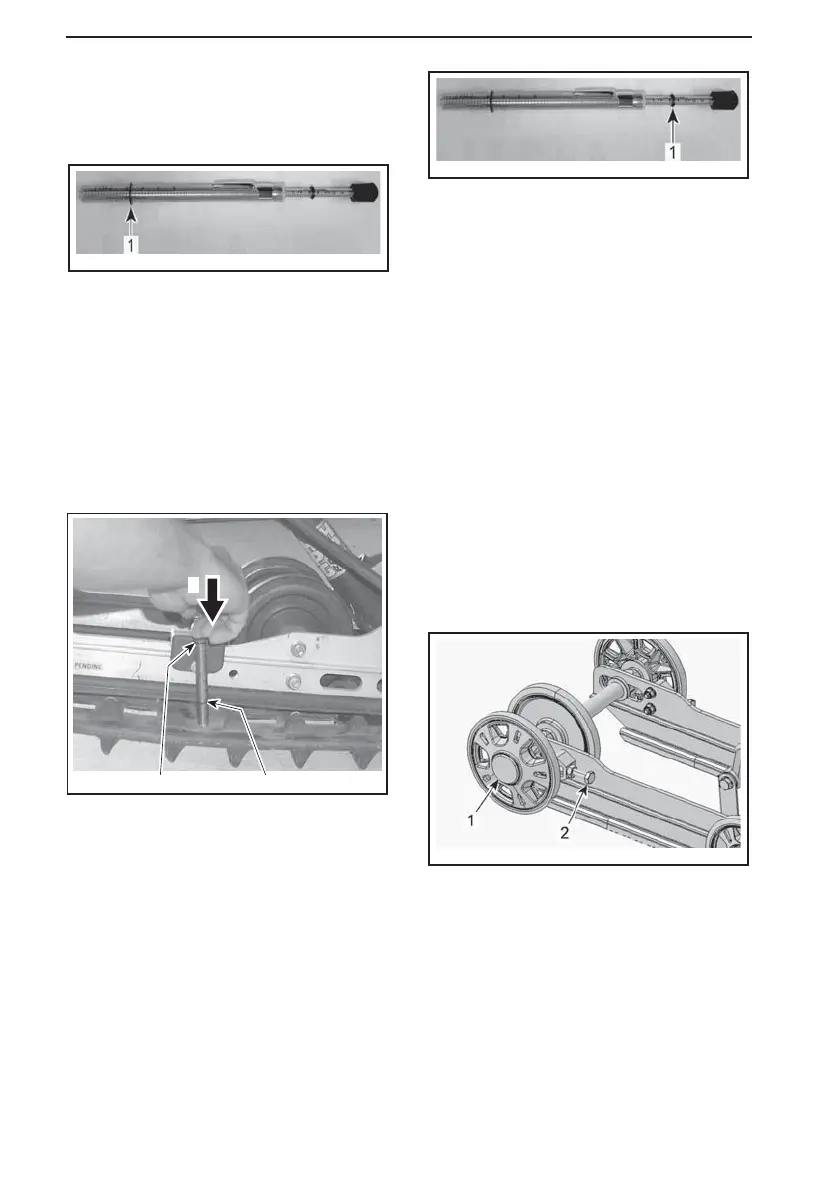

Track Tension Adjustment

1. Remove tether cord cap from en-

gine cut-off switch.

2. Remove rear wheel caps (if so

equipped).

3. Loosen the rear idler wheel retain-

ing screws.

4. Tighten or loosen both adjustment

screws to increase or decrease

track tension.

fmo2015-004-006_a

ADVENTURE LX

1. RH rear wheel cap

2. RH adjustment screw

116

______________

Loading...

Loading...