Chapter 8 Sample preparation

Page 8-10 MAN 0384

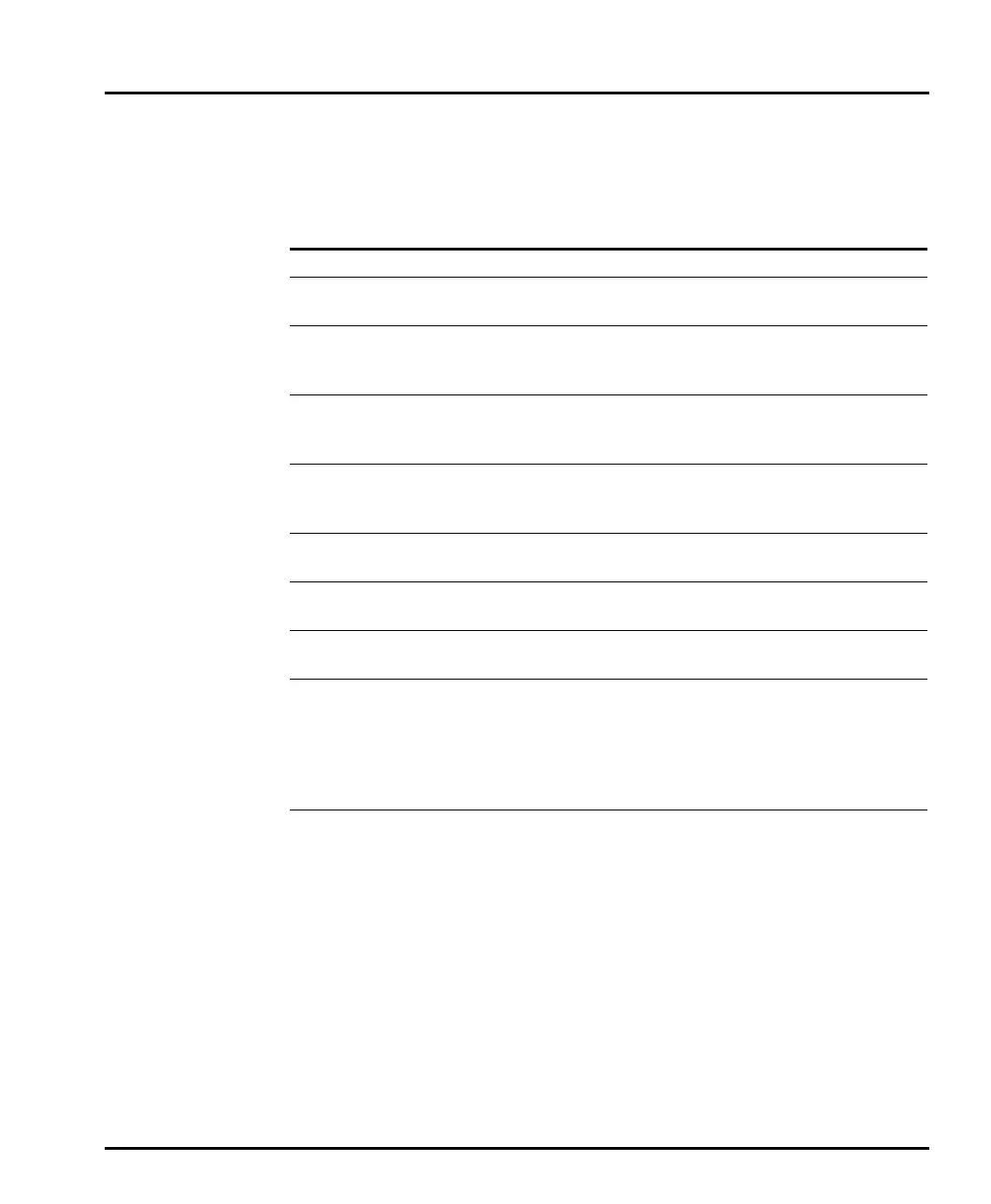

Symptoms of poor sample preparation

Use this table to identify sample dispersion problems:

Problem Symptom Action

Sample dissolving Obscuration decreases. Try another dispersant.

Dispersant contains

impurities

Poor background readings. Filter the dispersant

before use.

Bubbles within the

dispersant

Bubbles typically show as a

secondary peak at 100

microns.

Degas the system.

Sample floating on

the surface of the

dispersant

Sample seen on the surface

of the dispersant in the tank.

Add surfactant or

admixture.

Sample clumps

together

Obscuration decreases. Add surfactant or admix-

ture or use ultrasonic

action.

Sample sinks to the

bottom

Obscuration decreases as

the larger particles settle out.

Increase the pump/stirrer

speed.

Sample swells in

dispersant

Obscuration decreases. Try another dispersant.

Particles sticks to

the windows

Rapidly increasing

obscuration.

Use an admixture.

Condensation on

the cell windows

Rapidly increasing

obscuration.

If (and only if) the disper-

sant is water, add a quan-

tity of hot (not boiling)

water to the tank. If the

obscuration falls, conden-

sation is the problem.

Bubbles sticking to

windows

Difficulty in obtaining low

background despite many

rinses.

Drain the sampling tank.

The bubbles will burst. Fill

the system carefully with

degassed dispersant. In a

new system, adding

Decon 90 to the tank

overnight and rinsing 7 or

8 times will wet out the

cell surface and reduce

bubble formation.

MAN0384-1.0 Mastersizer 2000.book Page 10 Tuesday, March 20, 2007 8:56 AM

Loading...

Loading...