MAN B&W 7.00

Page 4 of 6

MAN Diesel

MAN B&W ME-GI engines

198 88 81-9.2

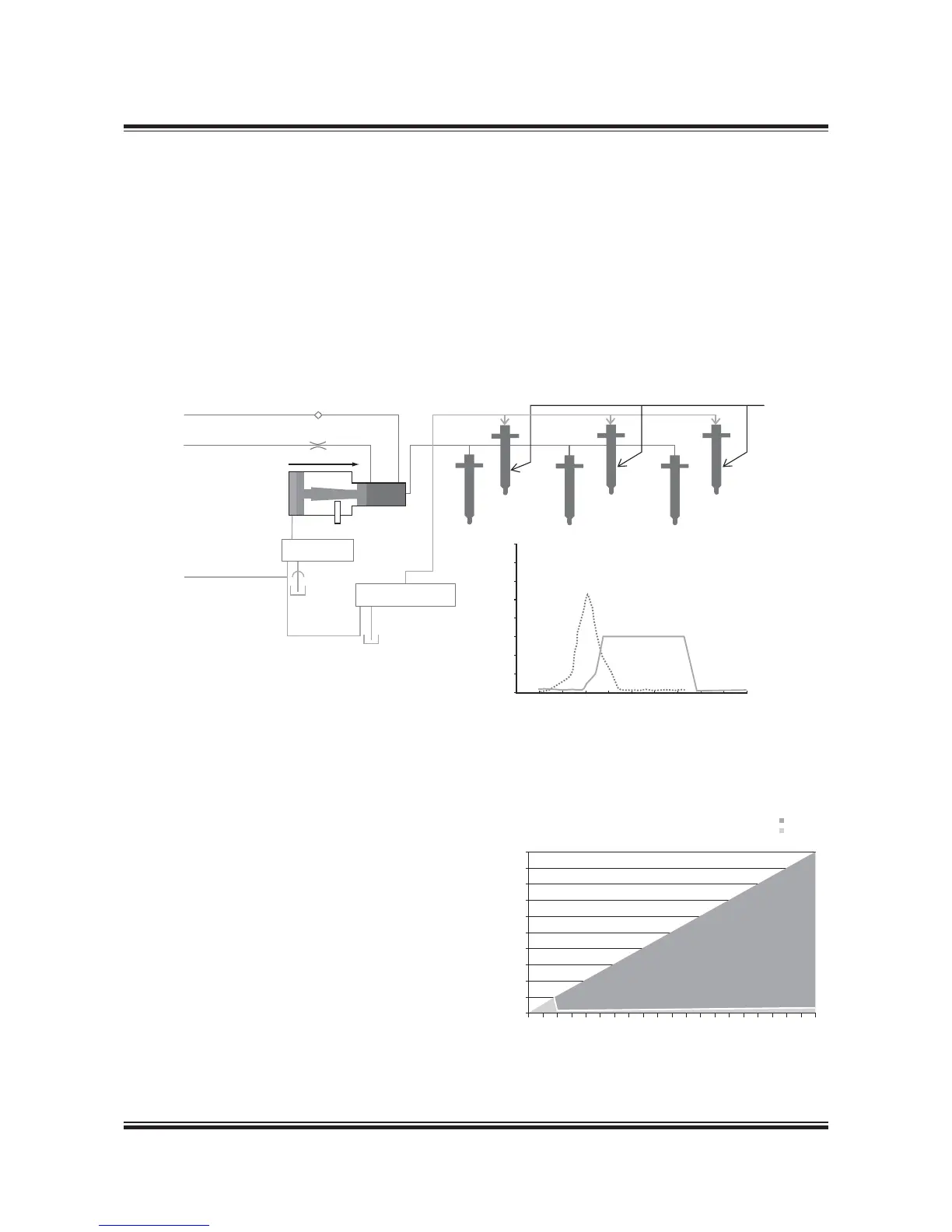

The ME-GI fuel injection system

As can be seen in Fig. 7.00.03a, the fuel oil pres-

sure booster, that pressurizes the supplied fuel oil

(pilot oil) during gas fuel operation mode, is con-

nected to the FIVA valve that controls the injection

of fuel oil to the combustion chamber.

The 300 bar hydraulic oil also pressurizes the

ELGI valve controlling the injection of the gas fuel.

By the engine control system, the engine can be

operated in the various relevant modes: ‘gas op-

eration’ with minimum pilot oil amount, ‘specified

dual fuel operation’ (SDF) with injection of a fixed

gas amount and the ‘fuel-oil-only mode’.

Fig. 7.00.03a: The ME-GI fuel injection system

178 53 63-3.2

800

600

400

200

Bar abs

0

0

5

10

15

20

30

35

25

40

45

Deg. CA

Pilot oil pressure

Control oil pressure

Low pressure fuel supply

Fuel return

Measuring and

limiting device.

Pressure booster

(800-900) bar)

Position sensor

FIVA valve

ELGI valve

300 bar hydraulic oil.

Common with

exhaust valve actuator

Gas

The system provides:

Pressure, timing, rate shaping,

main, pre- and post-injection

Injection

Gas

Fuel oil

100%

90%

80%

70%

60%

50%

40%

30%

20%

10%

0%

0

10 20 30 40 50 60 70 80 90 100

Min. pilot oil 3% at MCR

% Fuel

Engine load %

178 65 93-8.1

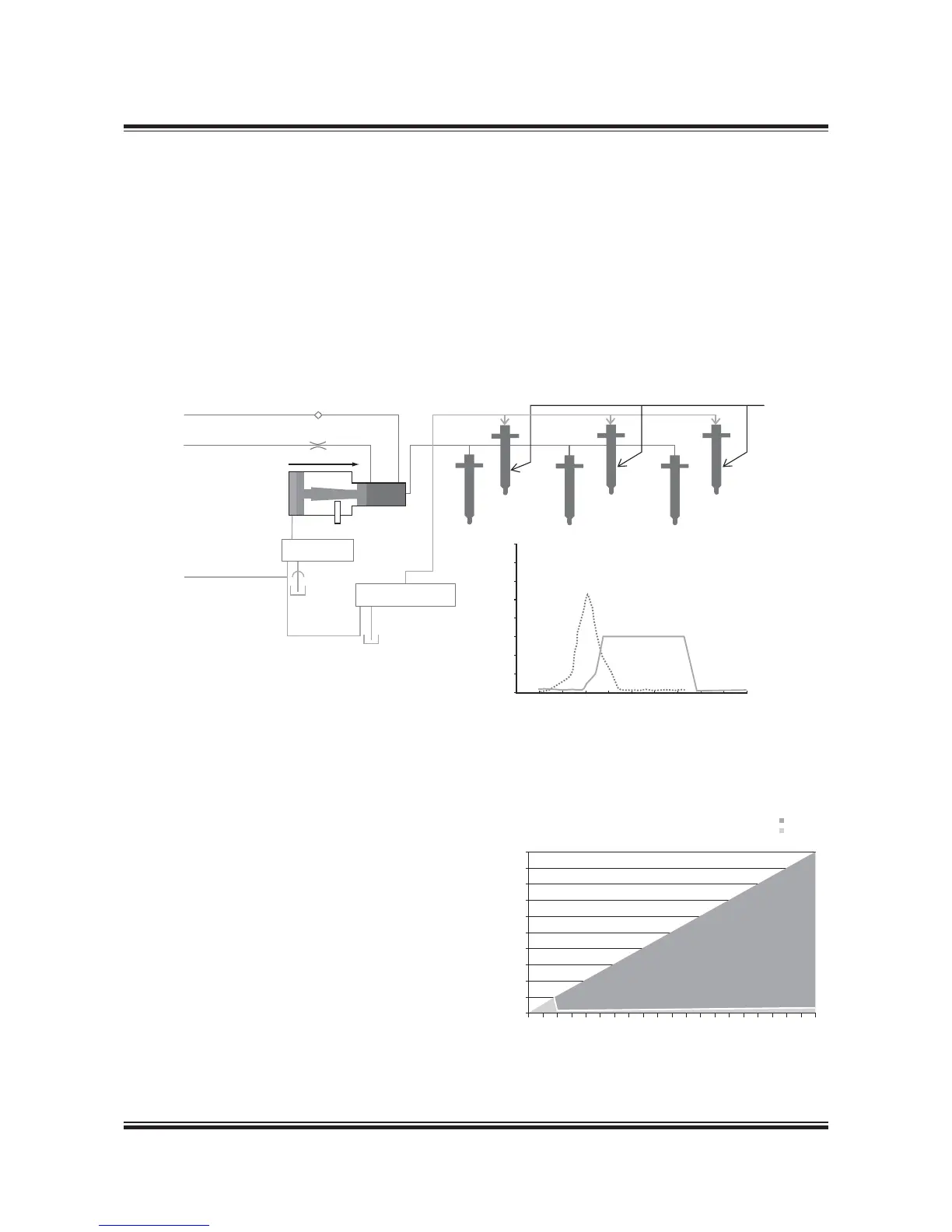

Fig. 7.00.03b: Fuel index in gas operation mode

Pilot oil injection amount versus engine load

Gas operation is possible down to 10% load.

The minimum pilot oil amount in gas operation

mode is 3% at MCR (in L

1

), see Fig. 7.00.03b. In case

the engine is derated, the pilot amount is relatively

higher as calculated in CEAS, see Section 20.02.

Engine output with minimum pilot oil amount can

be obtained even with an LCV of the fuel gas as

low as 38 MJ/kg. Below 38 MJ/kg, a higher pilot

oil amount might be required.

For guaranteed Specific Gas Consumption (SGC)

on test bed, the minimum LCV is 50 MJ/kg with a

tolerance of ±5%.

Loading...

Loading...