1

2

3

Replacing valve seat insert

105

Removing valve seat insert

Note:

If the valve seat inserts have to be changed it is necessary to change the valve guides too, as

otherwise exact refacing of the valve seat inserts after the replacement cannot be guaranteed.

For these reasons previously mentioned the tool for removing and installing valve guides and

valve seat inserts was also designed in such a way that if this tool is used valve seat inserts can

be replaced only together with the valve guides, i.e. valve guides, however, can also be changed

alone.

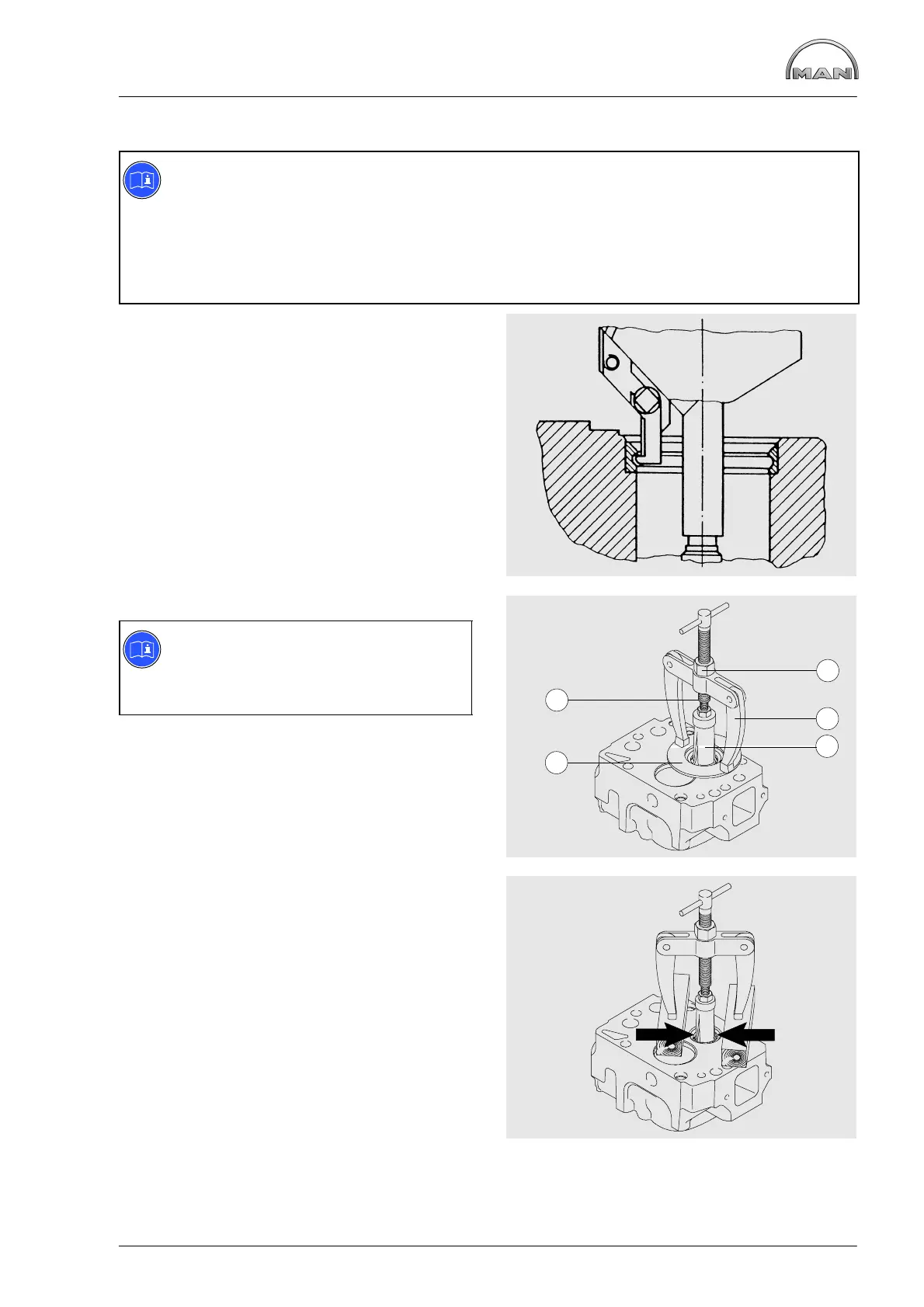

Fig. 1

Use a valve seat machining tool (valve seat lathe)

to cut an approx. 3−4 mm wide groove in the valve

seat insert.

Insert internal puller À into the groove and

tighten it.

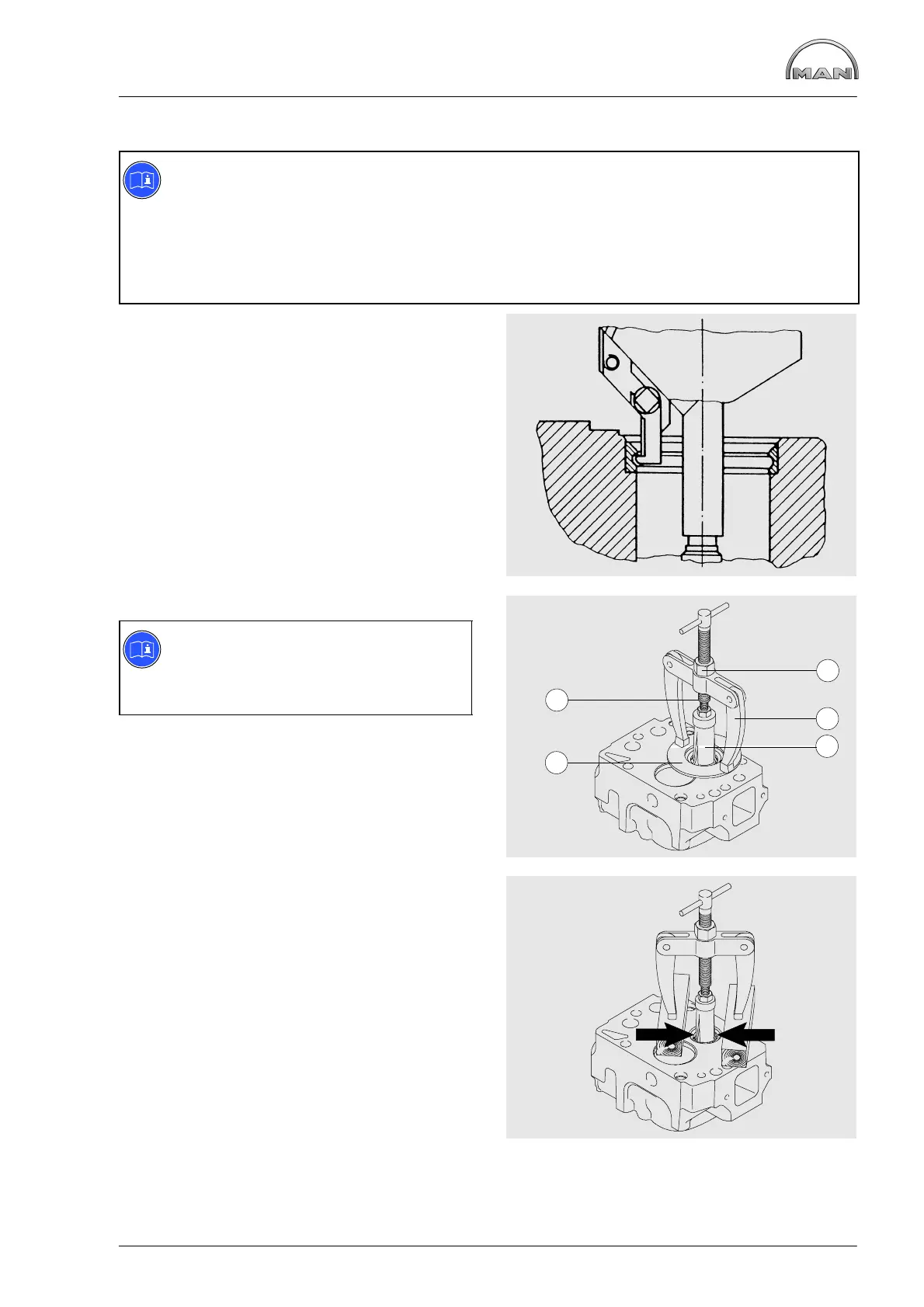

Fig. 2

Note:

To avoid damage to the cylinder head

sealing face, lay disc Á or similar item

under the arms  of the support.

Turn threaded spindle à into the internal puller À,

align the arms  of the support and pull out valve

seat insert by turning the nut Ä.

Clean contact face of the seat insert in the cylinder

head.

Fig. 3

If no valve seat machining tool is available, the

following procedure may be followed:

D Apply circular weld bead on the valve seat

using an arc welding set (arrows)

D then pull out valve seat insert

D Clean contact face of the seat insert in the

cylinder head

1

2

3

4

5

Loading...

Loading...