1

2

3

4

Refacing valves

110

Fig. 1

Apply abrasive paste to tapered area on the valve

seat.

Oil valve guide and insert valve.

Fig. 2

Use valve refacer to reface valve seat by applying

moderate axial pressure and describing a turning

motion.

Caution:

Keep valve stem and valve guide free of

abrasive paste.

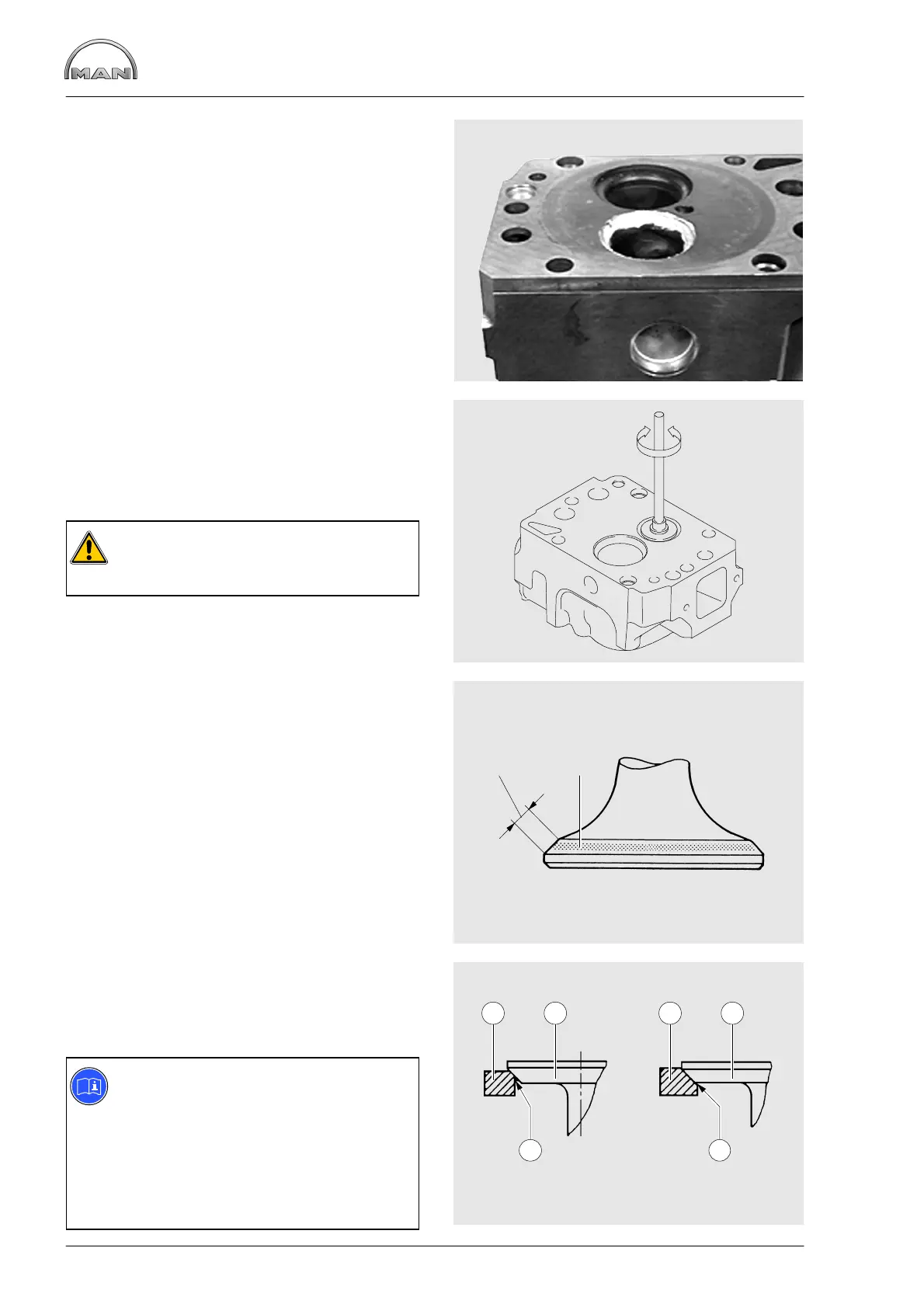

Fig. 3

The valve seat must have a faultless, closed

grinding pattern Á.

The grinding pattern width is correct if the valve

seat insert is in order.

À Valve tapered area

Á Valve seat

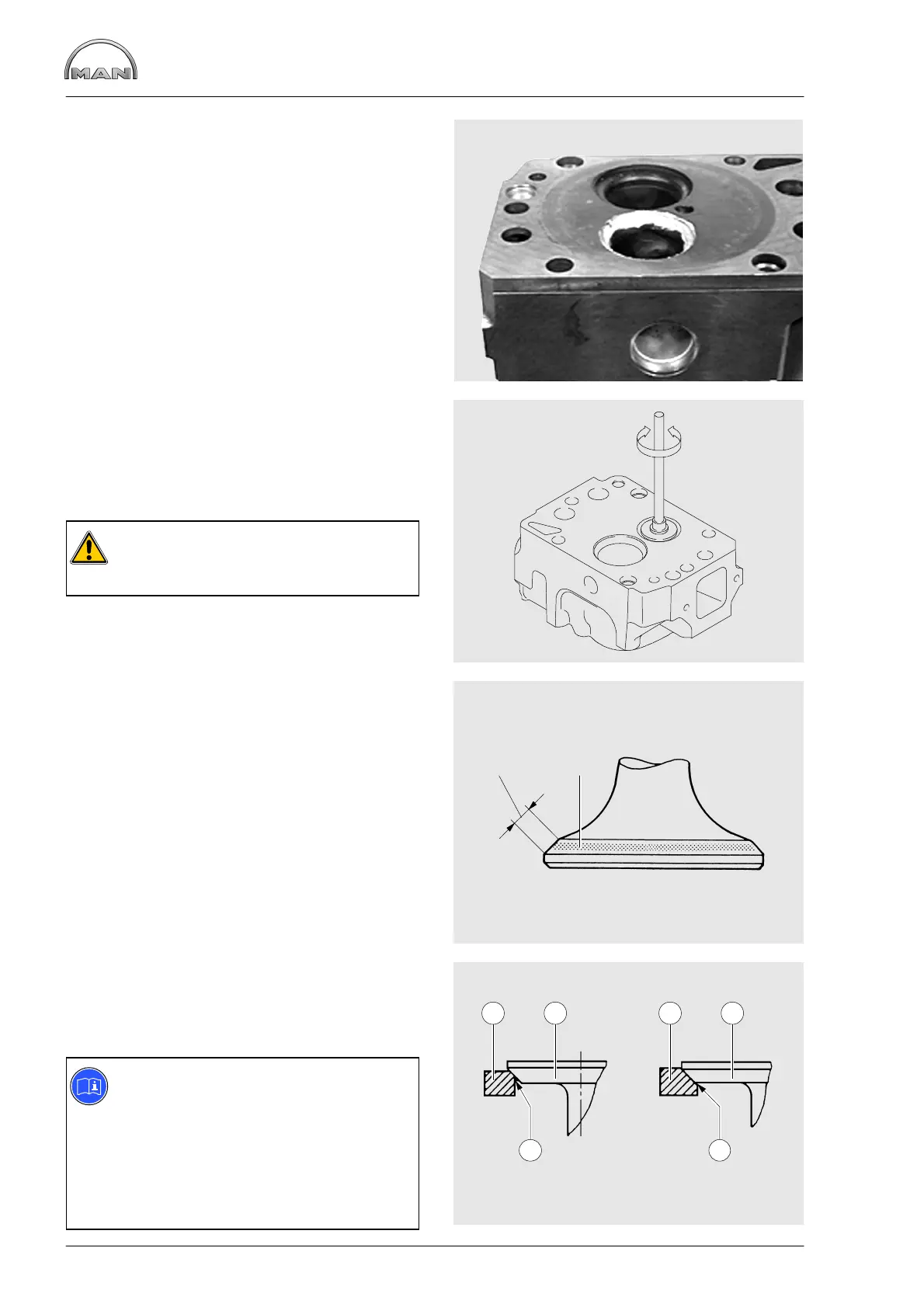

Fig. 4

À Valve seat insert

Á Valve

Valve seat good

à Valve seat too wide

Note:

Valve seats which are too wide tend to

accumulate coking residues,

− valves become leaky −

Valve seats that are too small prevent

rapid discharge of heat from the valve

disc to the cylinder head,

− valves burn −

1 2

1 2 1 2

34

Loading...

Loading...