Â

50H - WEEKLY SERVICING OR EVERY 50 HOURS OF SERVICE

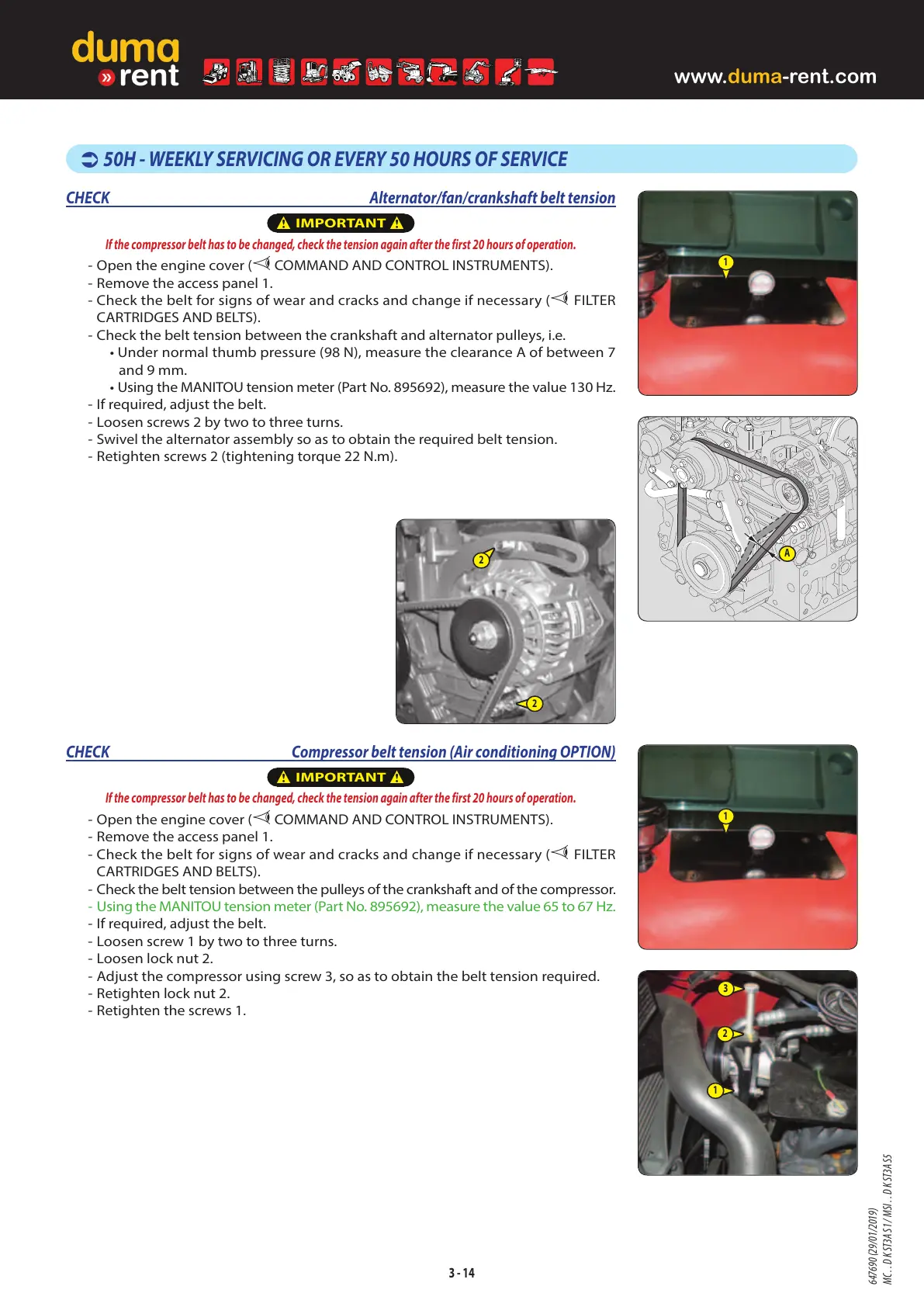

CHECK Alternator/fan/crankshaft belt tension

IMPORTANT

If the compressor belt has to be changed, check the tension again after the first 20 hours of operation.

- Open the engine cover ( COMMAND AND CONTROL INSTRUMENTS).

- Remove the access panel 1.

- Check the belt for signs of wear and cracks and change if necessary ( FILTER

CARTRIDGES AND BELTS).

- Check the belt tension between the crankshaft and alternator pulleys, i.e.

• Under normal thumb pressure (98 N), measure the clearance A of between 7

and 9 mm.

• Using the MANITOU tension meter (Part No. 895692), measure the value 130 Hz.

- If required, adjust the belt.

- Loosen screws 2 by two to three turns.

- Swivel the alternator assembly so as to obtain the required belt tension.

- Retighten screws 2 (tightening torque 22 N.m).

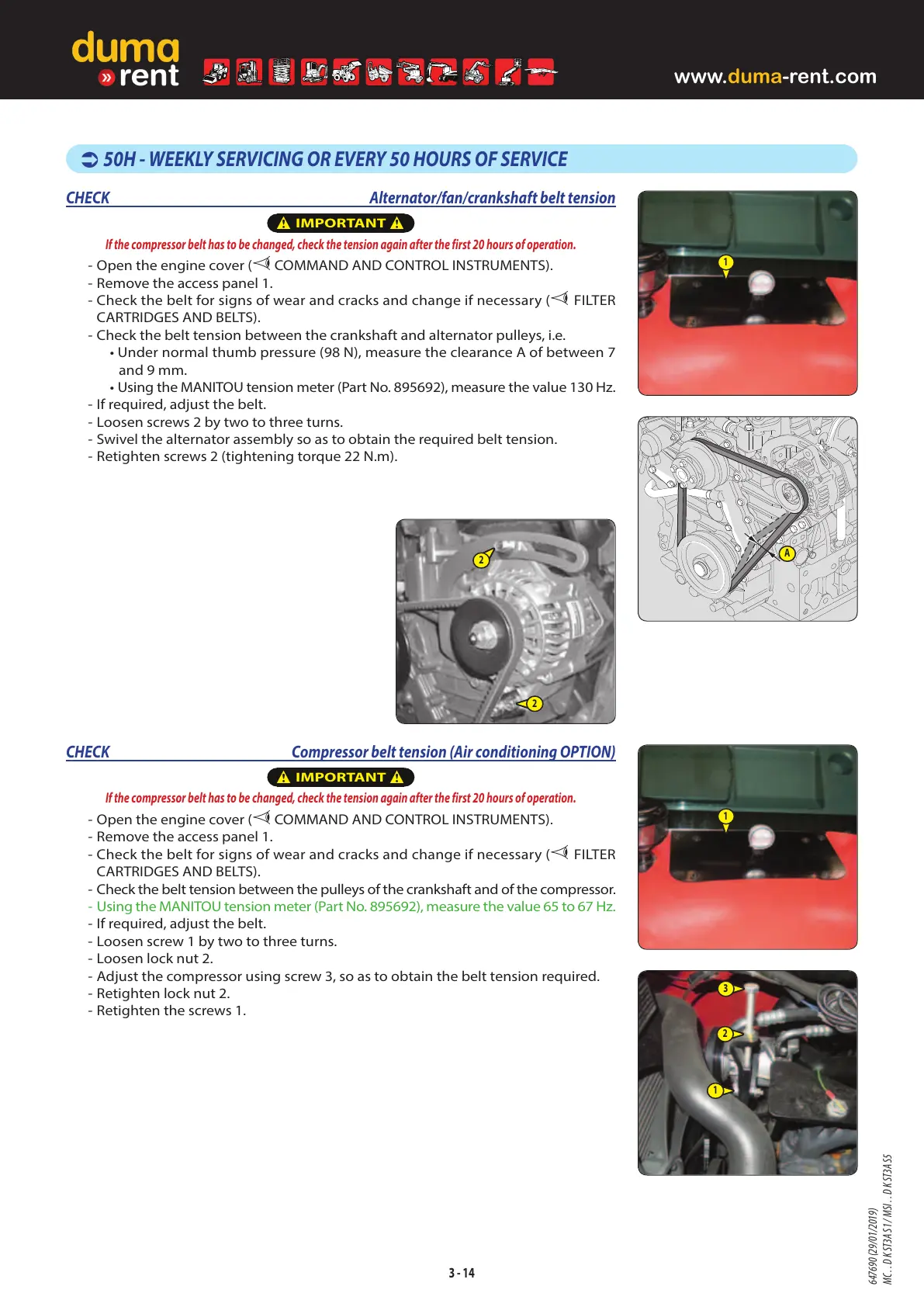

CHECK Compressor belt tension (Air conditioning OPTION)

IMPORTANT

If the compressor belt has to be changed, check the tension again after the first 20 hours of operation.

- Open the engine cover ( COMMAND AND CONTROL INSTRUMENTS).

- Remove the access panel 1.

- Check the belt for signs of wear and cracks and change if necessary ( FILTER

CARTRIDGES AND BELTS).

- Check the belt tension between the pulleys of the crankshaft and of the compressor.

- Using the MANITOU tension meter (Part No. 895692), measure the value 65 to 67 Hz.

- If required, adjust the belt.

- Loosen screw 1 by two to three turns.

- Loosen lock nut 2.

- Adjust the compressor using screw 3, so as to obtain the belt tension required.

- Retighten lock nut 2.

- Retighten the screws 1.

3 - 14

A

2

2

1

1

2

1

3

647690 (29/01/2019)

Loading...

Loading...