BLEED Fuel supply circuit

These operations are to be carried out only in the following cases:

• A component of the fuel system replaced or drained.

• A drained tank.

• Running out of fuel.

- Ensure that the fuel level in the tank is sufficient and bleed in the following order:

- Open the engine cover (

COMMAND AND CONTROL INSTRUMENTS).

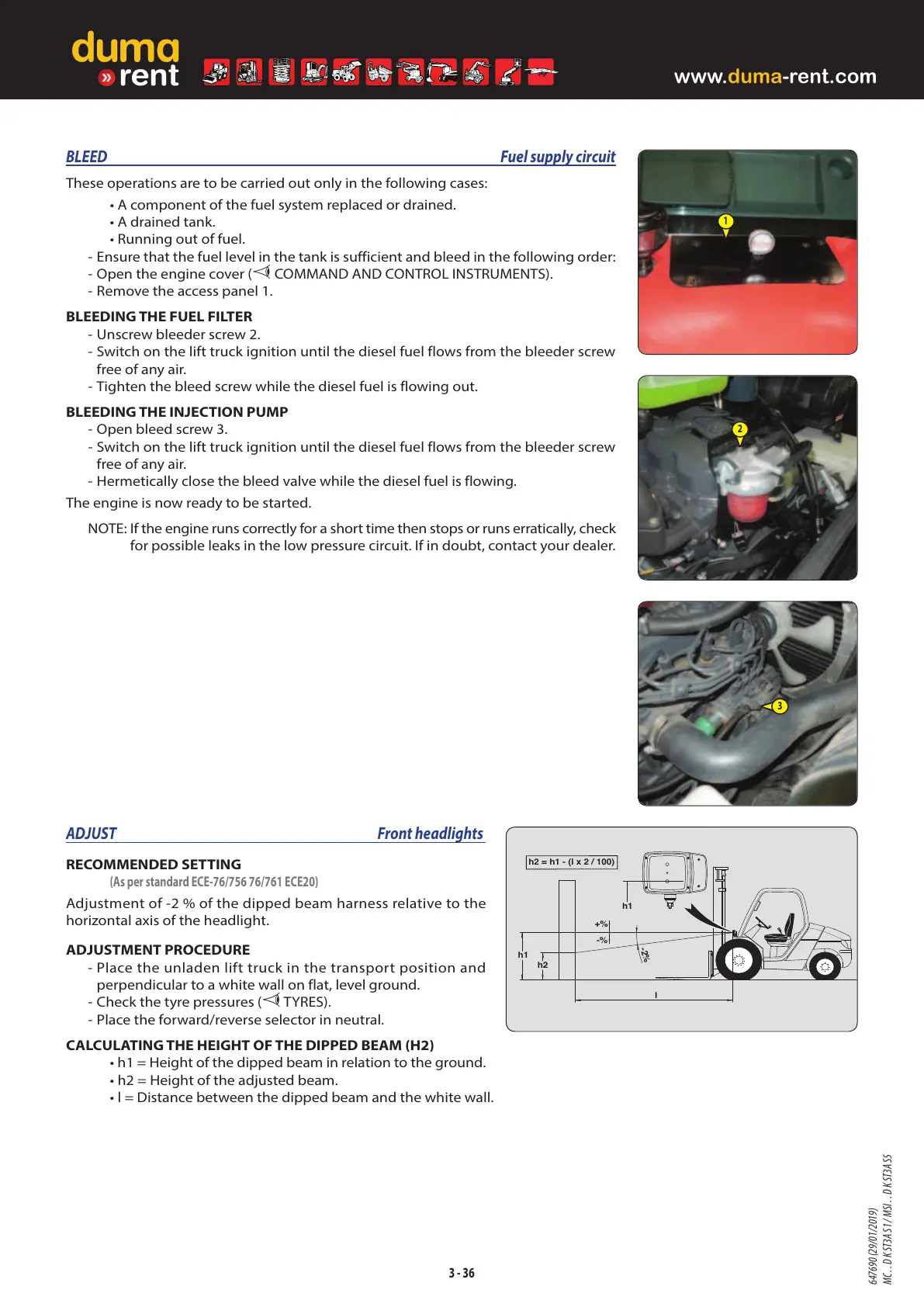

- Remove the access panel 1.

BLEEDING THE FUEL FILTER

- Unscrew bleeder screw 2.

- Switch on the lift truck ignition until the diesel fuel flows from the bleeder screw

free of any air.

- Tighten the bleed screw while the diesel fuel is flowing out.

BLEEDING THE INJECTION PUMP

- Open bleed screw 3.

- Switch on the lift truck ignition until the diesel fuel flows from the bleeder screw

free of any air.

- Hermetically close the bleed valve while the diesel fuel is flowing.

The engine is now ready to be started.

NOTE: If the engine runs correctly for a short time then stops or runs erratically, check

for possible leaks in the low pressure circuit. If in doubt, contact your dealer.

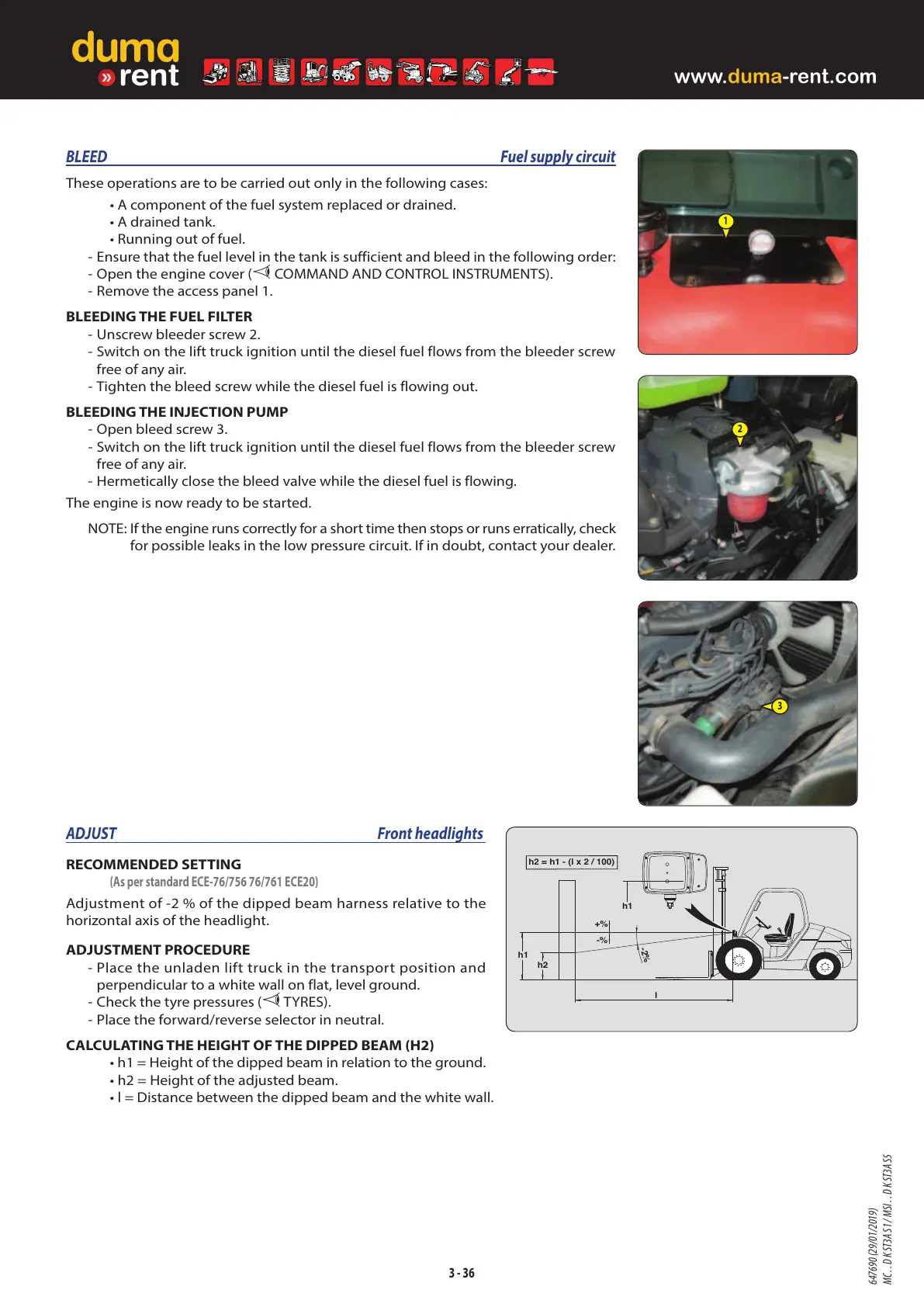

ADJUST Front headlights

RECOMMENDED SETTING

(As per standard ECE-76/756 76/761 ECE20)

Adjustment of -2 % of the dipped beam harness relative to the

horizontal axis of the headlight.

ADJUSTMENT PROCEDURE

- Place the unladen lift truck in the transport position and

perpendicular to a white wall on flat, level ground.

- Check the tyre pressures (

TYRES).

- Place the forward/reverse selector in neutral.

CALCULATING THE HEIGHT OF THE DIPPED BEAM (H2)

• h1 = Height of the dipped beam in relation to the ground.

• h2 = Height of the adjusted beam.

• l = Distance between the dipped beam and the white wall.

3 - 36

3

2

1

h1

+%

-%

h1

h2

-2%

h2 = h1 - (l x 2 / 100)

l

647690 (29/01/2019)

Loading...

Loading...