OPERATING CONTROLS AND PROCEDURES CD15 OPERATOR MANUAL

3-16 Published 3-30-2018, CTRL 636-05

OPERATING OUTRIGGER CONTROLS

To Raise and Lower the Outriggers

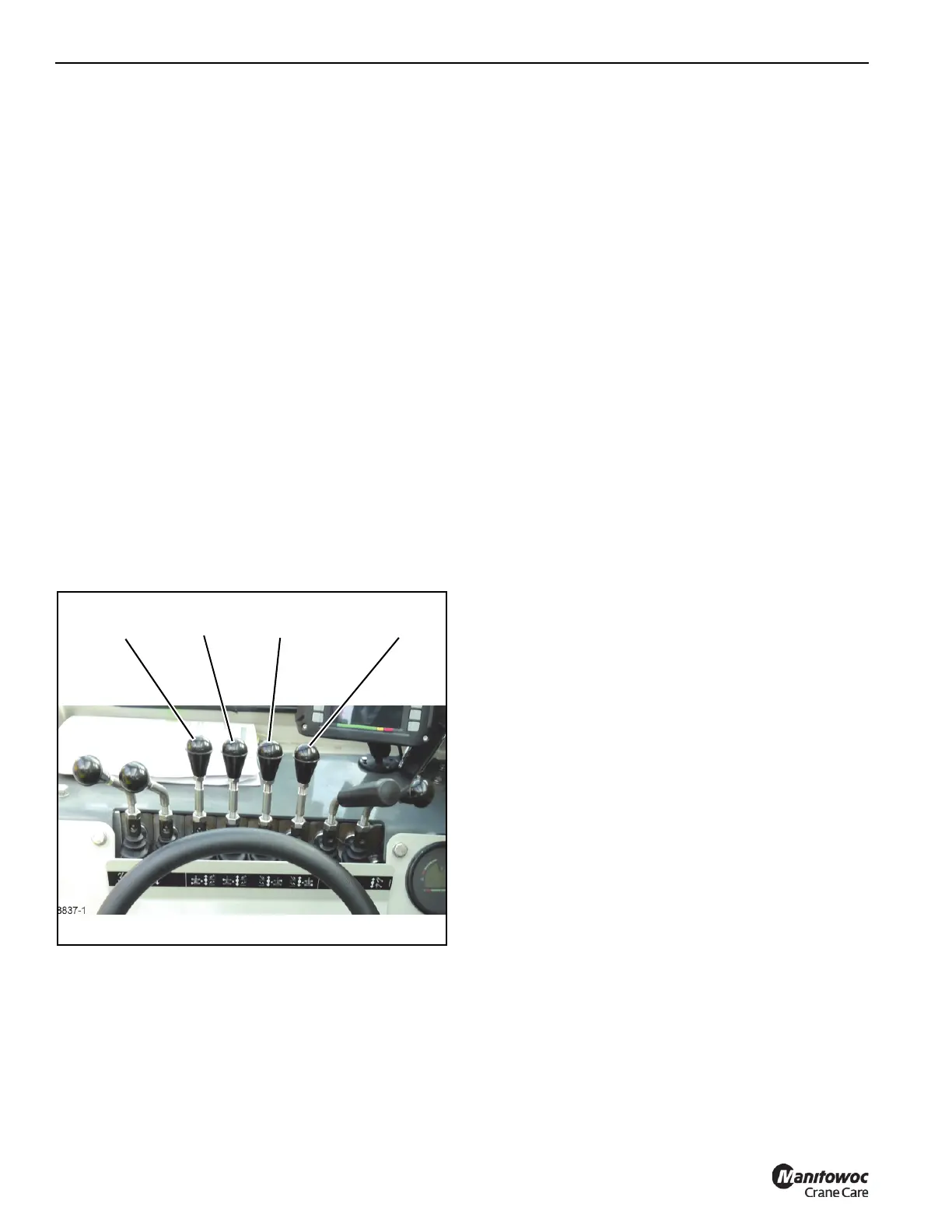

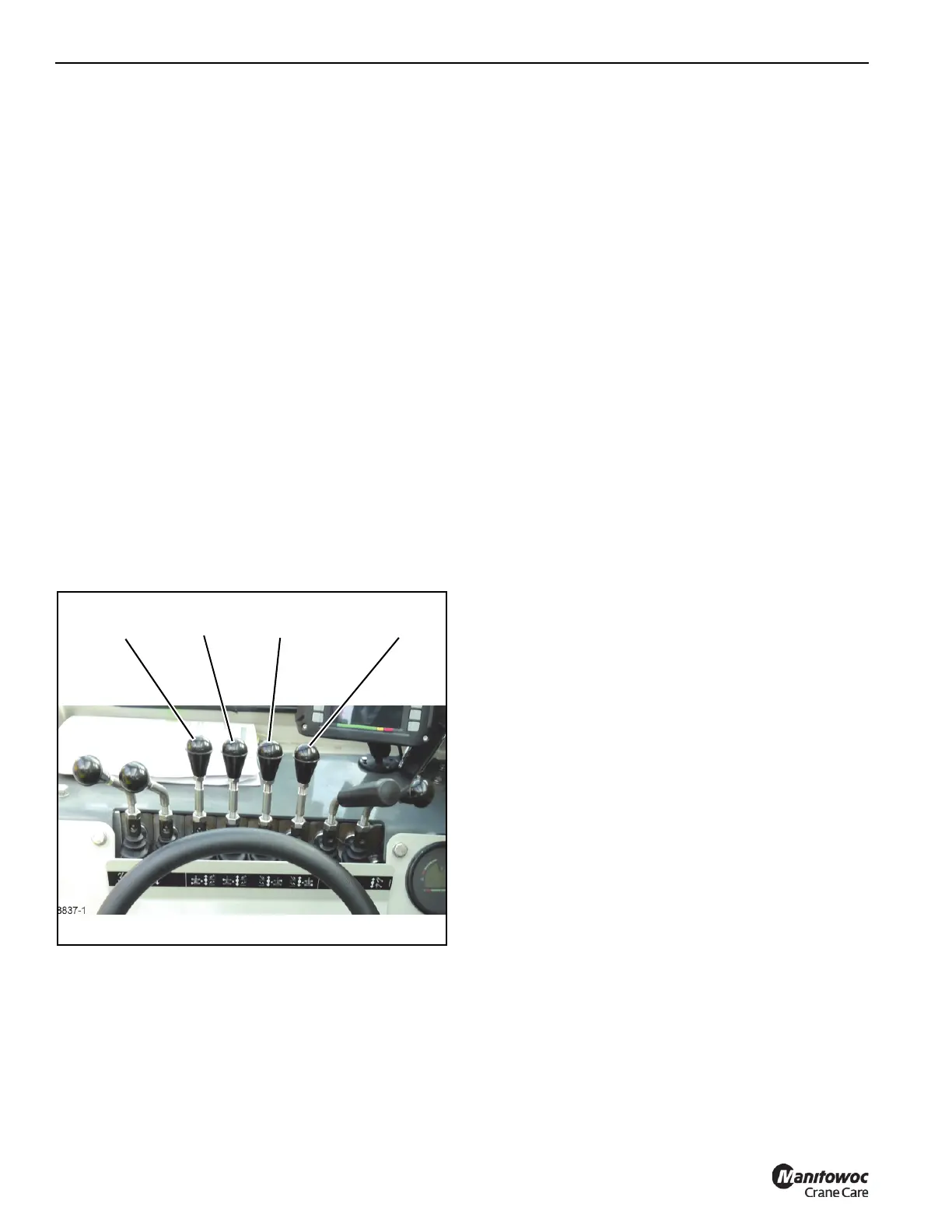

Each outrigger is independently controlled (Figure 3-24).

Two or more outriggers may be simultaneously lowered or

raised by simultaneously actuating the controls for each of

the outriggers.

The back up/outrigger alarm at the rear of the carrier will

sound while any outrigger control is being operated.

1. Determine which outriggers are to be raised or lowered;

left, right or all.

2. To Lower - (Figure 3-25) Run the engine at idle speed

(accelerator pedal released). Move the control lever

forward to the LOWER position and hold it in position.

Press the accelerator pedal to increase the engine

speed, which will accelerate the outward movement of

the outrigger. Release the accelerator pedal and the

outrigger control lever when the outrigger is extended.

3. To Raise - (Figure 3-25) Pull the control lever back to

the RAISE position and hold it in position. Press the

accelerator pedal to increase the engine speed, which

will accelerate the retracting speed of the outrigger.

Release the accelerator pedal and the control lever

when the outrigger is fully raised.

Outrigger Monitoring System (OMS)

Optional—Standard in North America

The Outrigger Monitoring System (OMS) aids the operator

by using an indicator (15, Figure 3-6) on the control panel

that lights when all outriggers are fully deployed. The OMS

uses four proximity sensors, one per outrigger beam, to

identify when an outrigger beam is fully extended.

Set up of the outriggers is the same for cranes equipped with

OMS; refer to Operating Outrigger Controls, page 3-16. The

OMS indicator only indicates the fully extended position of

the outrigger beam and should not be used to deploy the

beam.

Outriggers fully retracted or outriggers fully extended are the

only outrigger positions documented on the Load Charts.

Each proximity switch senses the presence of it’s respective

outrigger beam until the beam reaches it’s fully extended

position.

Proximity switch outputs are wired in series such that when

all outrigger beams are fully extended, each proximity switch

will no longer sense presence of it’s outrigger beam, the

output contact will then close illuminating the green indicator

on the control panel signaling all outriggers are fully

extended and lifts can be made per Outriggers Fully

Extended Load Chart.

Any outrigger beam not fully extended or functional failure of

any proximity switch will cause the indicator to not illuminate,

indicating the outrigger beams are not fully extended and lifts

can only be made per the Outriggers Retracted or On

Rubber Load Charts.

Outrigger beam position monitoring is not interfaced with the

RCL (if equipped). The crane operator is responsible for

selecting the correct load chart.

8837-1

FIGURE 3-24

Left Rear Left Front

Right Front

Right Rear

Loading...

Loading...