OPERATING CONTROLS AND PROCEDURES CD15 OPERATOR MANUAL

3-18 Published 3-30-2018, CTRL 636-05

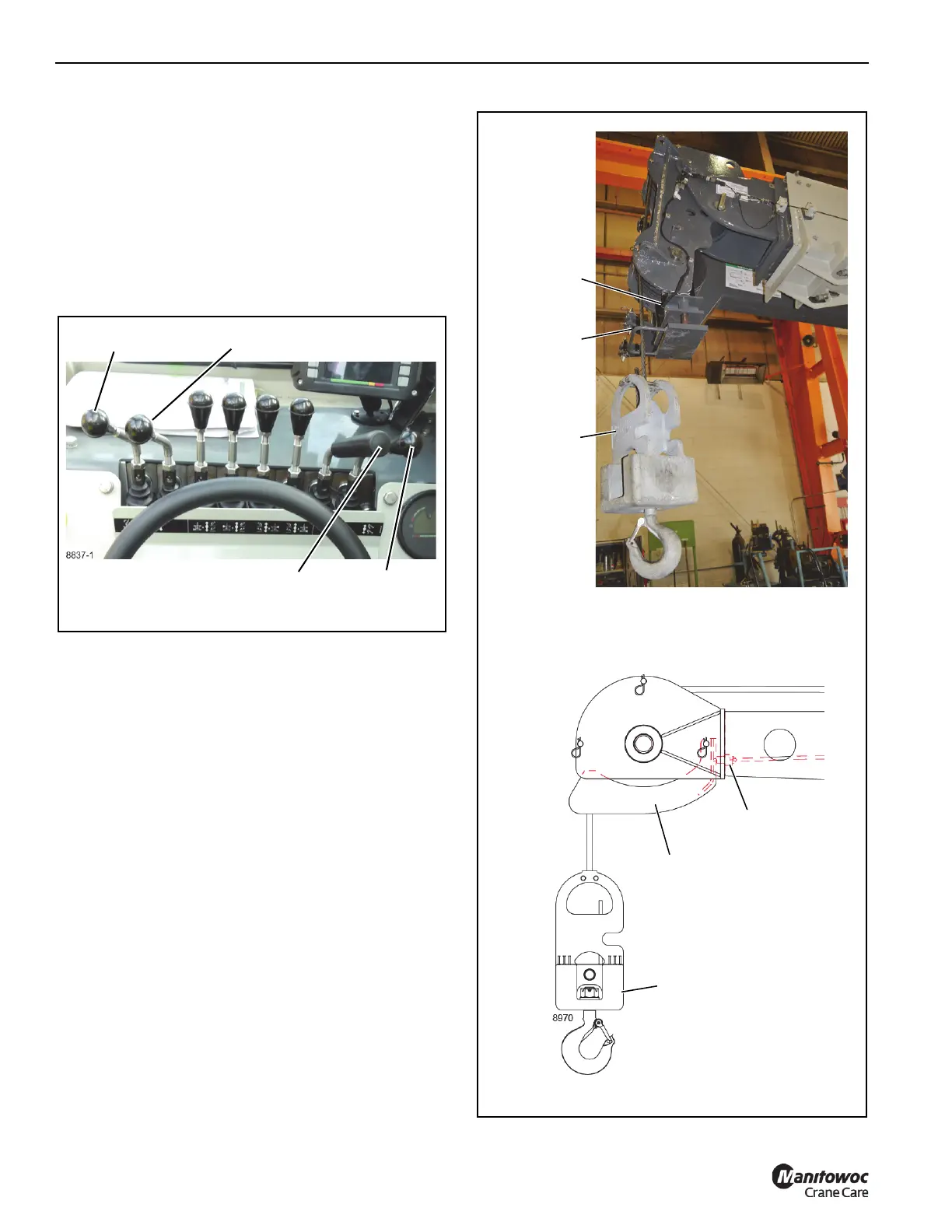

OPERATING CRANE CONTROLS

Four levers in the operator’s cab control the crane functions.

See Figure 3-26. These levers are connected directly to the

main control valves.

When operating each control, press the accelerator pedal to

increase engine speed to maximum RPM. Slowly move the

control lever. The farther the control lever is moved the faster

the function will operate. To stop function movement, move

the control lever to the neutral position, then lower the engine

speed to idle.

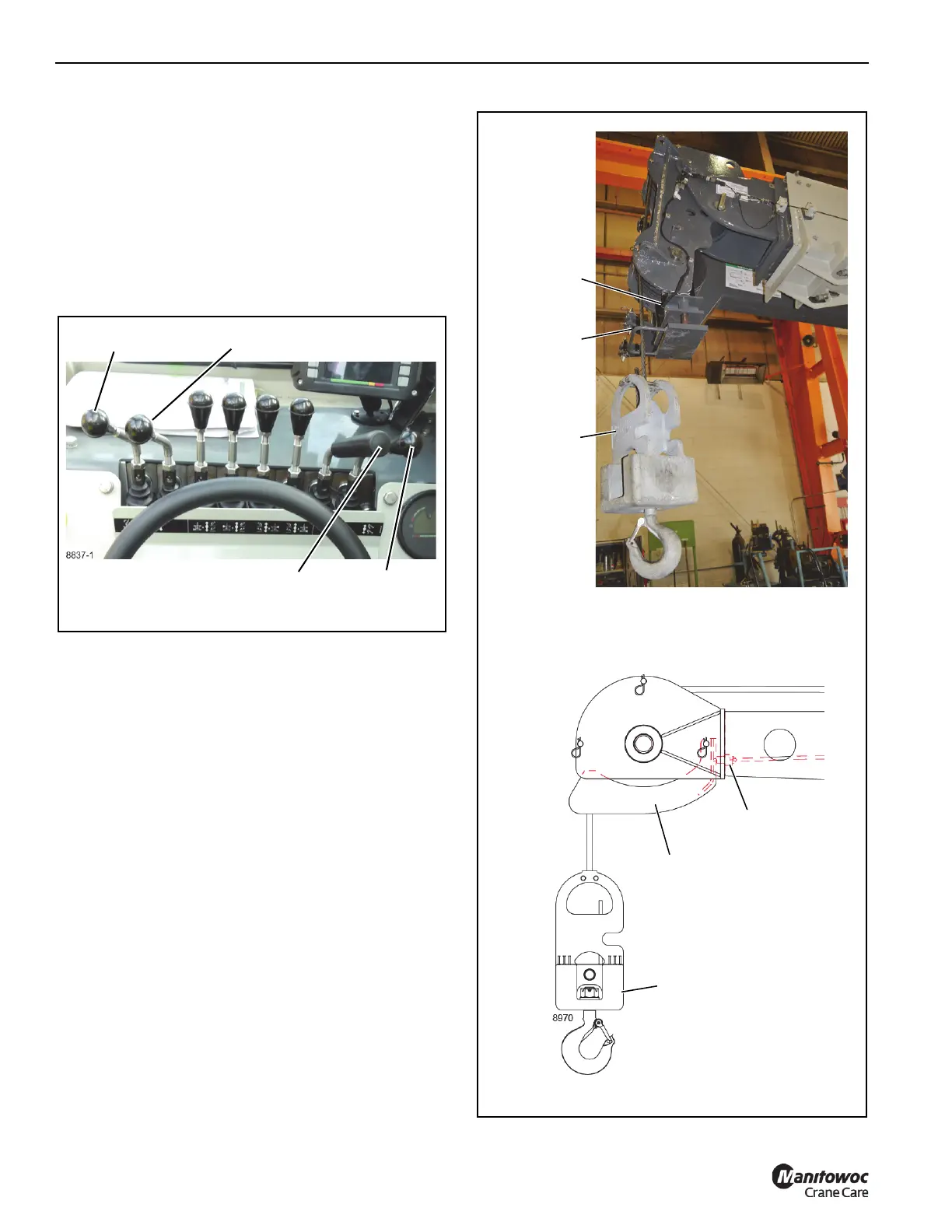

Anti-Two Blocking System

See Figure 3-27

This system inhibits the hook block or the downhaul weight

from being pulled into the boom or jib head during boom

extension, boom raising, and load hoisting operations.

If the hook block or the downhaul weight contacts the anti-

two-block bracket under the boom head or the anti-two-block

lever under the jib head, the limit switch is actuated.

The limit switch stops hydraulic oil flow to the telescope out,

boom lift, and hoist motor raise functions. A horn is activated

to give a warning to the operator in all cases.

Before operation can resume, the hook block or the

downhaul weight must be lowered away from the boom or jib

head.

NOTE: DO NOT disconnect the anti-two-block system.

Possible damage to the boom, hoist or crane could

result.

Swing Control

Telescope Control

Hoist Control

Boom Control

FIGURE 3-26

8911

Anti-Two-Block

Bracket

FIGURE 3-27

Limit Switch

Hook Block or

Downhaul

Weight

Anti-Two Blocking System — Boom

Downhaul

Weight

Anti-Two-Block

Lever

Limit

Switch

Anti-Two Blocking System — Jib

Loading...

Loading...