8-27

GRT9165 SERVICE MANUAL UNDERCARRIAGE

Published 10-01-2020 Control # 699-00

11. Pull the outrigger beam out of the outrigger box, re-

adjusting the lifting attachment to prevent the extension

cylinder from sliding out of the outrigger beam when the

beam clears the outrigger box.

12. Position outrigger beam on blocking material.

Inspection

Inspect outrigger beams for bends, evidence of cracks, or

other damage. Check outrigger beam internally for hydraulic

fluid, which may indicate a leaking cylinder, loose

connection, or damaged hydraulic line.

Installation

1. If removed, install wear pads (16) into bottom inside of

outrigger box using plates (15) and jam nuts (14). Apply

anti-seize compound to the wear pads (16).

2. If removed, install wear pads (19) and plates (18) to the

top of the outrigger beam using capscrews (17). Apply

anti-seize to the wear pads (19).

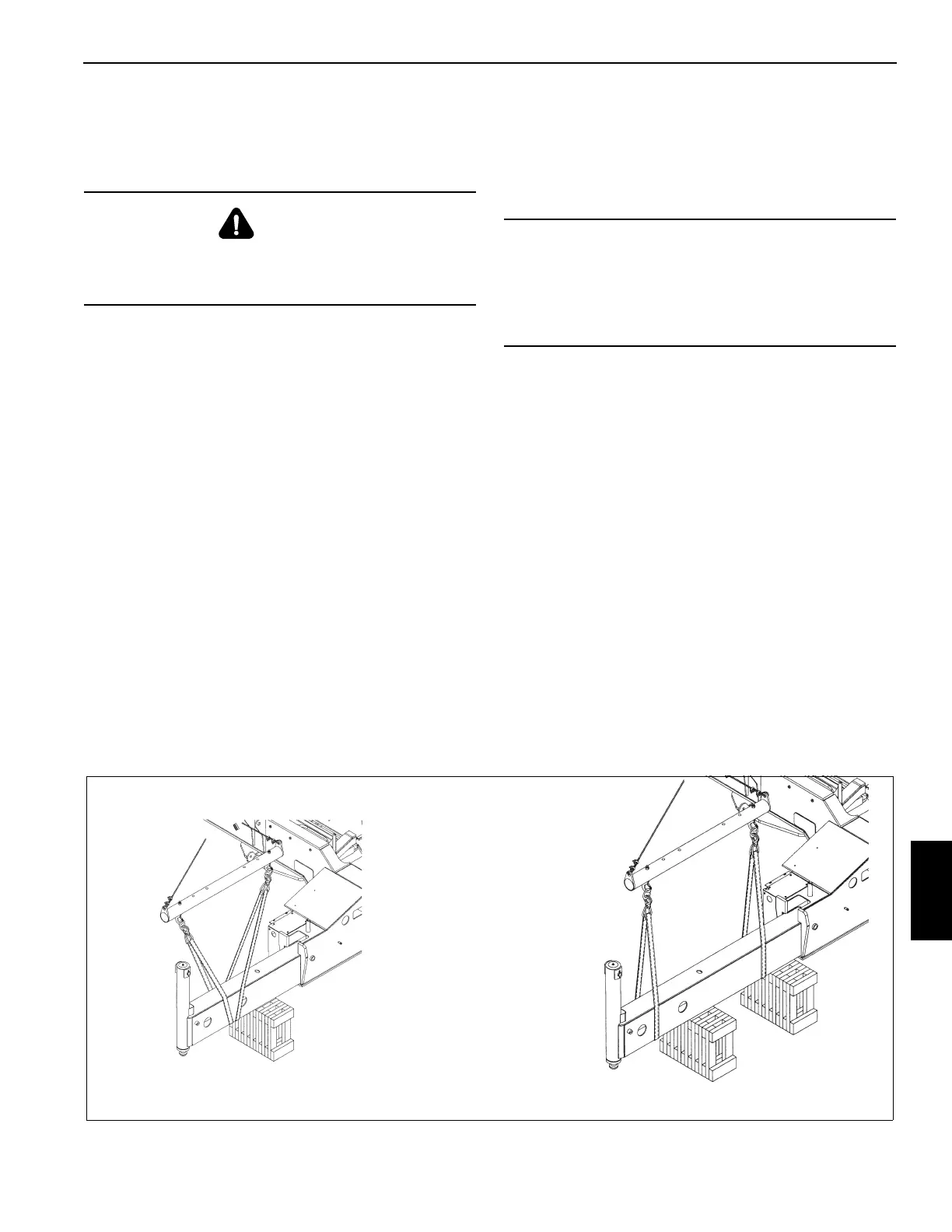

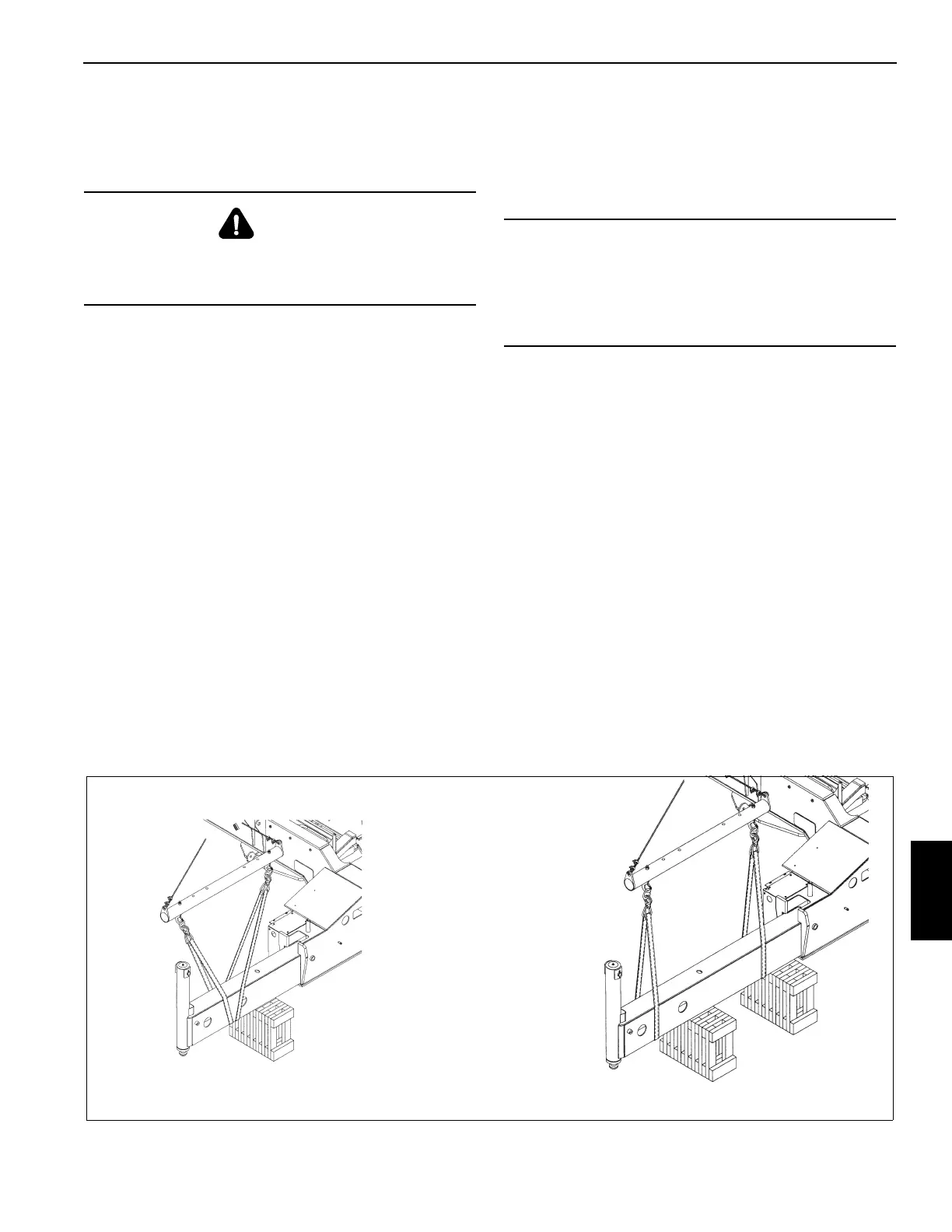

3. Attach an adequate lifting device of straps or belts to the

beam. Do not use chains, as they may nick the bottom

edges of the outrigger beam (see Figure 8-27).

NOTE: Outrigger beam assembly, with jack cylinder,

weighs approximately 984 kg (2169 lb).

4. Slide the beam into the outrigger housing and align the

cylinder bushing with the mounting hole. Be sure jack

cylinder hydraulic hoses do not get trapped against the

outrigger box during insertion.

5. Apply anti-seeze compound to the clevis pin (22,

Figure 8-26). Secure the cylinder barrel to the housing

with the clevis pin (22) and cotter pins (21).

6. Connect the hydraulic lines (20) as tagged during

removal. Connect the OMS electrical cable as tagged

during removal.

7. Fully extend and retract the outrigger beam, ensuring

the beam assembly rides on the top and bottom wear

pads.

8. Install outrigger end cover (13) with remove capscrews

(3), lockwashers (4), and washers (5).

9. Install lower outrigger cover (12) with washers (5),

lockwashers (4), capscrews (3), and retaining nuts (11).

10. If necessary, install grab handles (6) on ladder (10) with

capscrews (7), washers (8), and spacers (9).

11. If necessary, install grab handles (6) to upper cover (13)

with capscrews (3), lockwashers (4), and washers (5).

12. Install the outrigger boxes. For more information, see

the Operator Manual.

13. If extension cylinder was replaced, recalibrate the

outriggers.

DANGER

Be sure any blocking material used is capable of

supporting outrigger beam weight. Do not allow it to tilt or

slide.

CAUTION

Be sure that the piston side of all outrigger cylinders are

connected to the solenoid valve bank. Reversal of port

connection of the rod and piston sides could result in

severe damage to the cylinders as very high pressure

intensification will occur.

FIGURE 8-27

Rear Outriggers Shown

For reference only

Loading...

Loading...