3 Removal and Disassembly

14

Meritor Maintenance Manual MM-15103 (Issued 07-17)

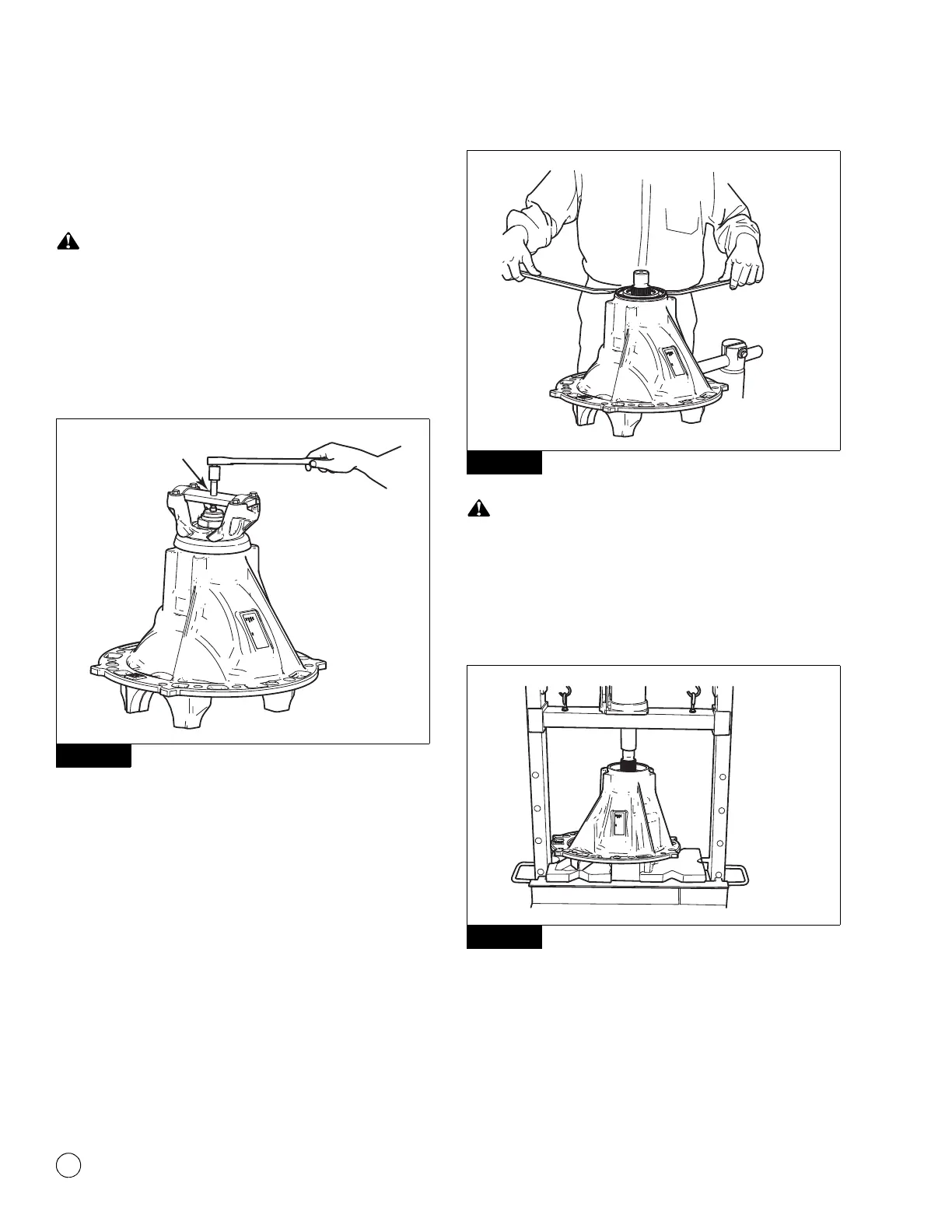

2. Remove the nut and washer, if equipped, from the drive pinion.

Figure 3.27.

3. Remove the yoke or flange bar.

If the yoke and flange are difficult to remove from the drive

pinion during disassembly, use a puller. Do not use a hammer

or mallet, which can damage components and affect driveline

alignment and end play.

4. Remove the yoke from the drive pinion. If the yoke is tight on

the pinion, use a puller. Figure 3.28.

Figure 3.28

NOTE: Always use a new oil seal during reassembly. Don’t reuse a

seal that’s been removed.

5. Use appropriate prying tools to remove the unitized oil seal

from the carrier. Place the blades of the prying tools under the

flange to remove the oil seal. Figure 3.29.

Figure 3.29

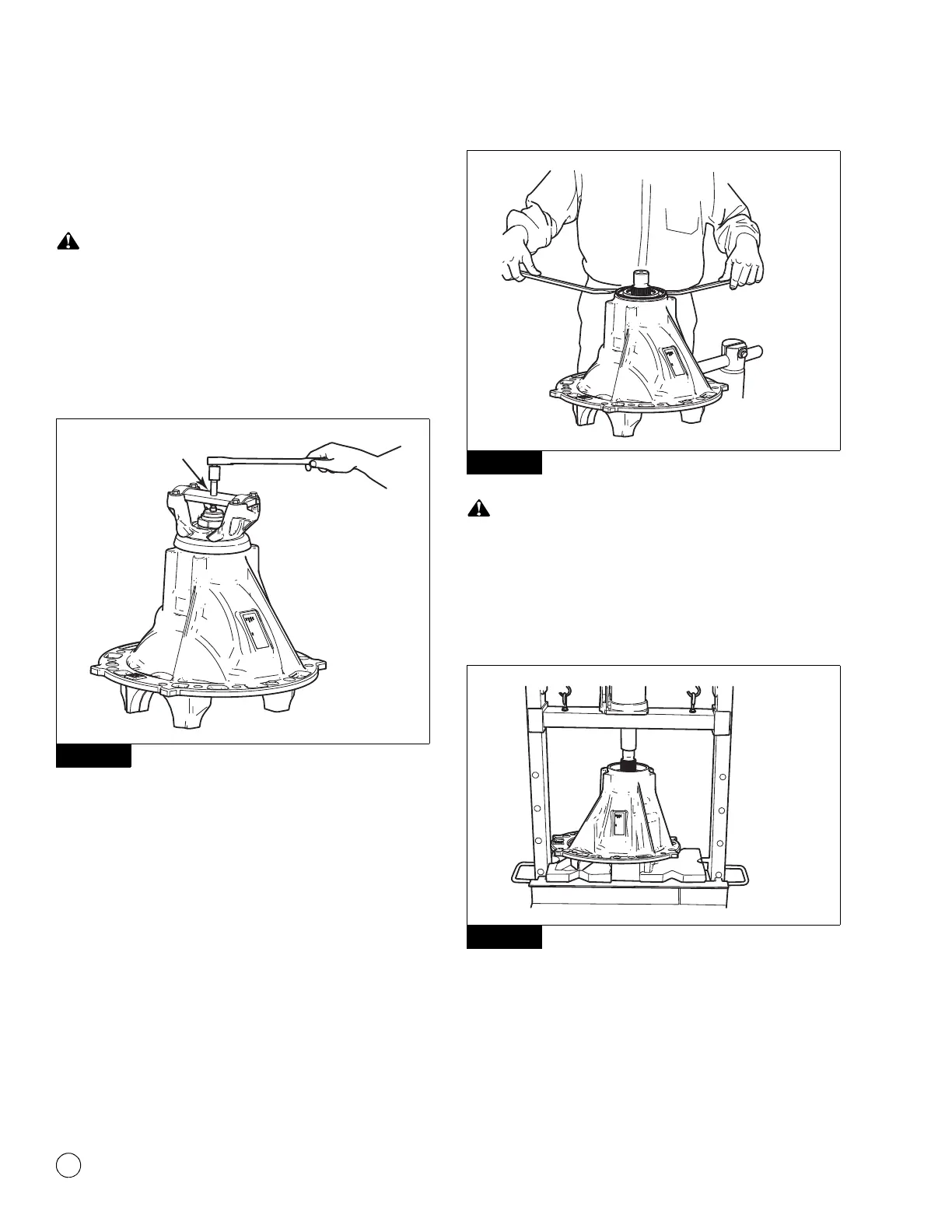

Observe all warnings and cautions provided by the press

manufacturer to avoid damage to components and serious

personal injury.

6. Place the carrier assembly in a press with the threaded end of

the pinion shaft pointing UP. Figure 3.30.

Figure 3.30

7. Press the pinion shaft out of the outer bearing cone. Do not let

the pinion shaft drop to the ground after being pressed out.

Figure 3.30.

8. Remove the outer bearing cone from the carrier.

Figure 3.28

Figure 3.29

Figure 3.30

Loading...

Loading...