MC³ 24.96.EX O&M Manual Page 27 08/14/01 4:34 PM/LDD

The feedrate Logical Output alarms are delayed by settable time parameters, “High Delay” and

“Low Delay” to prevent frequent cycling. In addition, there is a “Startup Delay” that is active when

the feeder is starting up, from either a blocked state or a zero setpoint. The Main Screen displays

are not delayed. See List of Logical Outputs on page 41 for more information on the specific

outputs affected.

The mode determines the kind if deviation that is controlling the Hi Rate and Lo Rate alarms and

the indicators on the main screen. There are three feedrate limit switch operating modes:

FeedRate HI/LO

When this mode is selected, the feedrate must be between the values entered into the

Limit Switch numeric parameters for High Feedrate and Low Feedrate.

Feedrate Rel Dev

This mode activates the logical outputs when the feedrate deviates from the setpoint by a

percentage of the current setpoint. The limits are entered into the parameters High

Relative Deviation and Low Relative Deviation. As an example, if High Relative

Deviation is set to 10 %, Low Relative Deviation is 5 % and the current setpoint is at 10

lb/min, the rate alarm outputs would be active when the feedrate is above 11.00 lb/min

and below 9.5 lb/min. If the setpoint changed to 5.00 lb/min, the outputs would be active above

5.5 lb/min and below 4.75 lb/min.

Feedrate Setpoint Deviation

In Feedrate Setpoint Deviation, the logical outputs will turn on if the feedrate deviates from the

setpoint by fixed values, set in High Rate and Low Rate deviation. For example, if the parameters

High Feedrate Deviation is set to 2.00 lb/min and Low Feedrate Deviation 1.00 lb/min

and the setpoint is 10.00 lb/min, the High Rate Alarm output would turn on when the

feedrate exceeds 12.00 lb/min and the Low Rate Alarm output would turn on when the

feedrate falls below the 9.00 lb/min.

The Overload and Underload limits are limits on the Belt Load set to cause a General Alarm if the

boundaries are exceeded for any reason. These boundaries are set to inform operators of a

condition that may have caused serious damage to the feeder.

There are also two delays involved with the rate alarm outputs. This is the high delay time and the

low delay time. These are the times from which the pertinent alarm first occurs and when you wish

for the alarm l outputs to come on.

There are upper and lower limits for each of these modes which are called HI or LO. The values

for each set of limits are located in the numeric section of the menu.

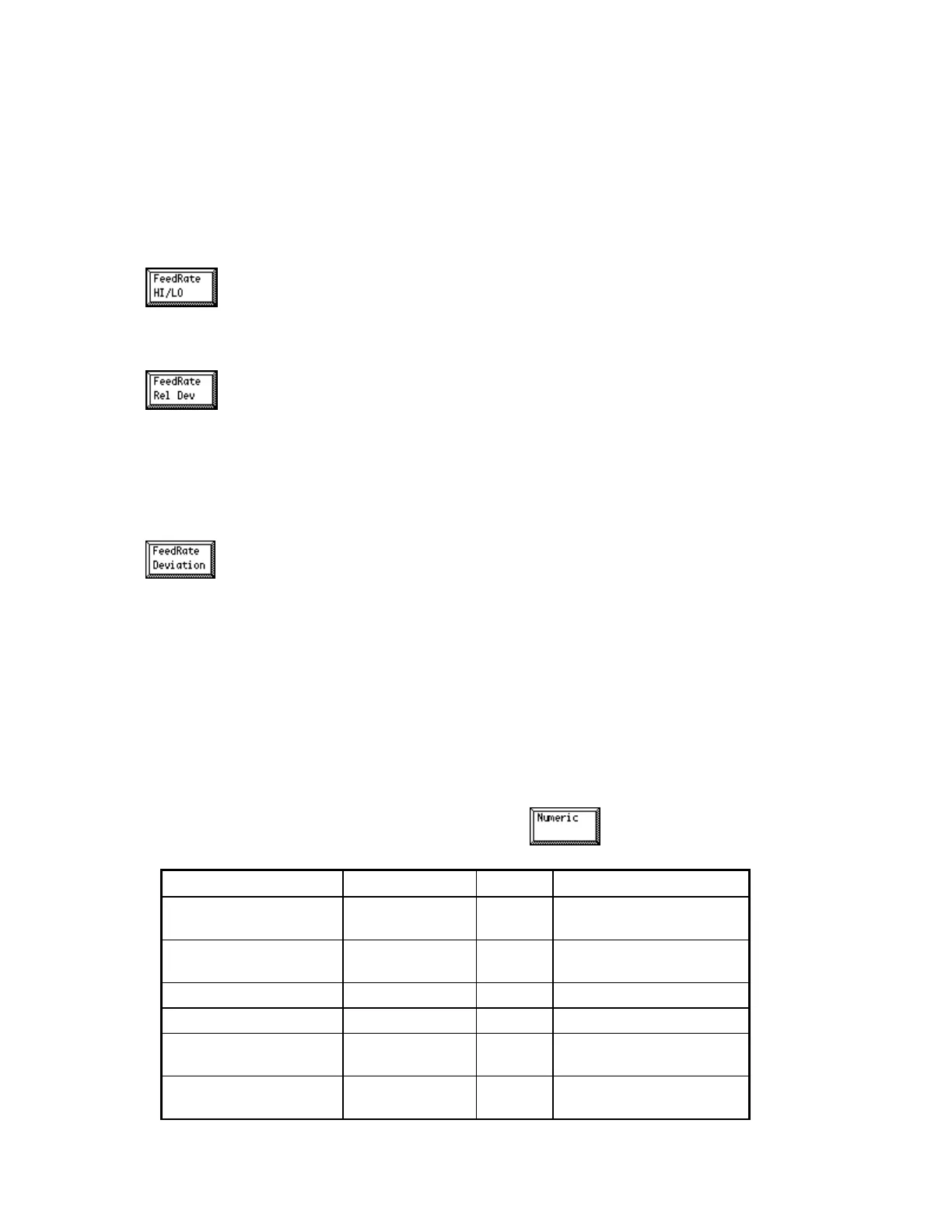

Numeric Parameters

To enter numeric values for the Limit Switches, touch . The display will be a Numeric

Entry Screen. Use the directions on page 9 to change the value of the parameter.

Parameter

Default Min Max

High Feedrate 90% of Design

Feedrate

0 150% of Design Feedrate

Low Feedrate 10% of Design

Feedrate

0 150% of Design Feedrate

High Relative Deviation 10% 0 % 100 %

Low Relative Deviation 10% 0 % 100 %

High Feedrate

Deviation

10% of Design

Feedrate

0 Design Feedrate

Low Feedrate Deviation -10% of Design

Feedrate

0 Design Feedrate

Loading...

Loading...