MC³ 24.96.EX O&M Manual Page 30 08/14/01 4:34 PM/LDD

Stepper Brushless pulse generator.

Frequency Frequency generator.

Mode

Mode determines if direction detection is to be utilized. For direction detection, a quadrature

encoder must be connected to the MC³, channel A and/or B. A quadrature encoder allows the MC³

to determine when the belt is moving and will only generate a speed signal if the belt is moving in a

forward direction. This is useful for when the belt is stopped and vibration at the tacho can cause

pulses to be sent to the controller. If only one tacho line is to be used, then the signal must be

attached to the channel A input (see Tacho on page 68) and the mode must be set to NO

DIRECTION.

If direction detection is needed and you are not sure if your encoder is right hand or left hand, run

the feeder and switch between right and left hand detection until a speed signal is present.

NO-DIRECTION - Direction of tacho is undetermined. The MC³ will use pulses from channel A

only to determine the speed signal.

R-HAND - The MC³ will only generate a speed signal if a right hand rotational direction is detected.

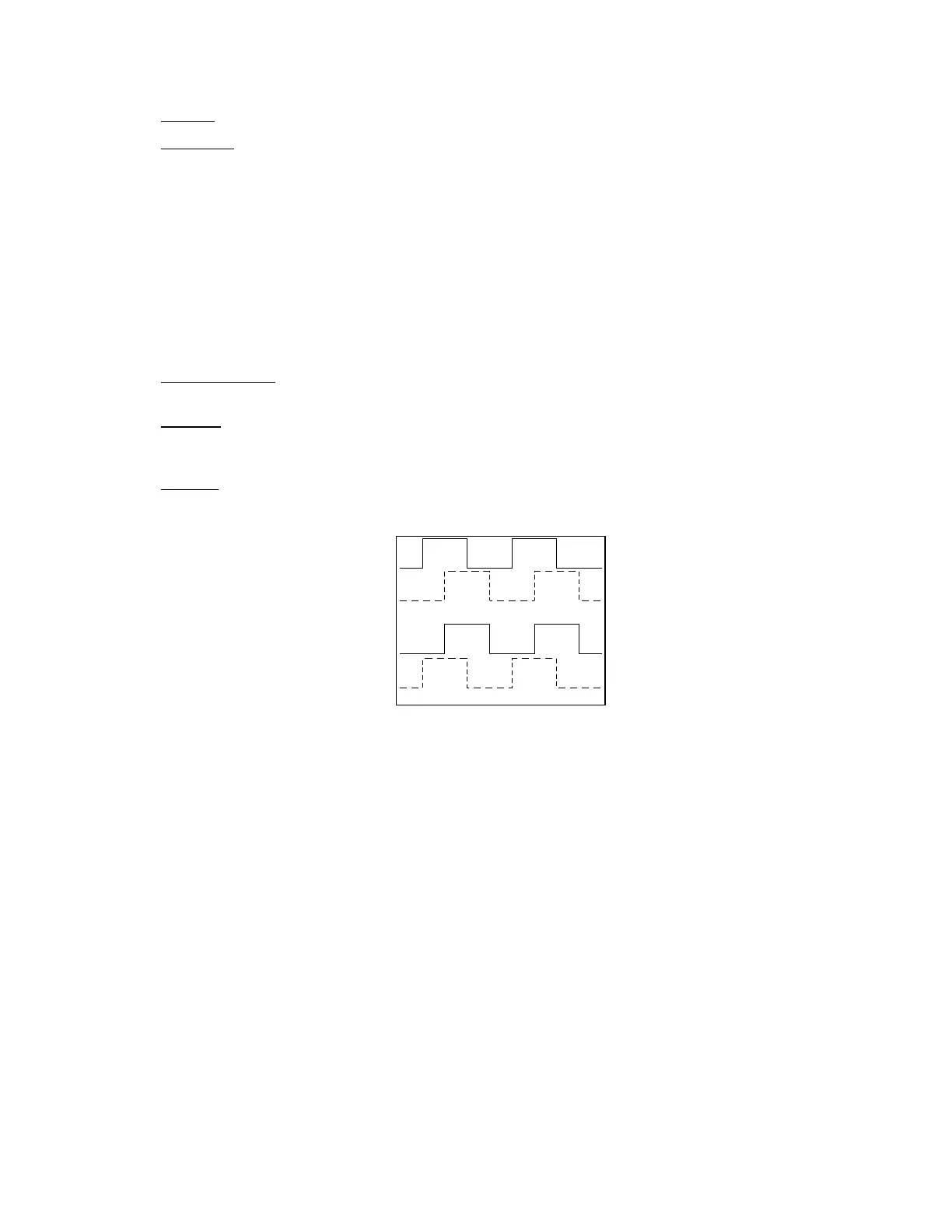

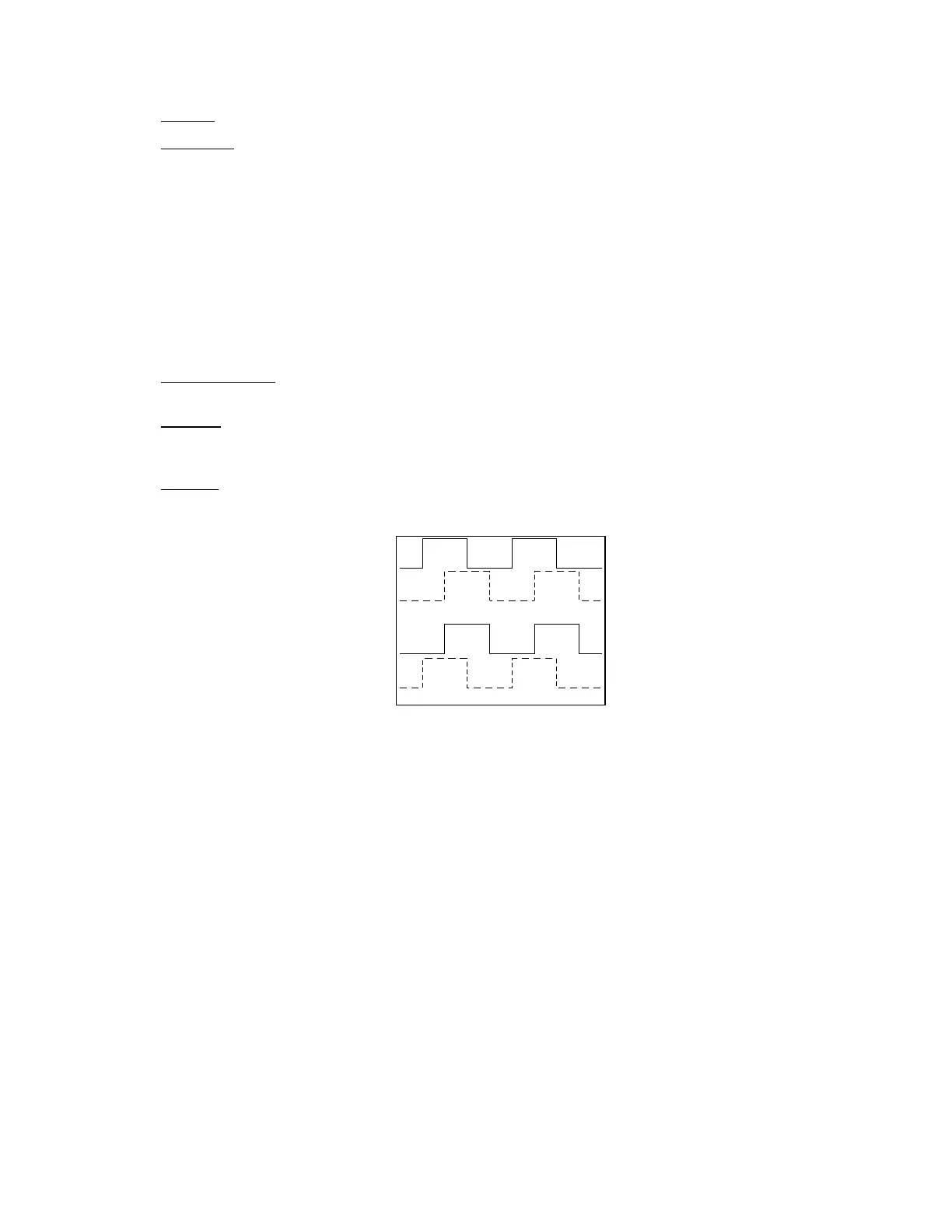

The MC³ determines right hand rotation as channel A leading channel B (see diagram

below.)

L-HAND - The MC³ will only generate a speed signal if a left hand rotational direction is detected.

The MC³ determines left hand rotation as channel B leading channel A (see diagram

below.)

A Leads B - R HAND

A

B

B

B Leads A - L HAND

A

Speed Sensing Operational Mode

The lower left button is used to toggle between different operational modes of the belt sped

sensing. The following operational modes are available:

NONE No tacho is used at all. The speed is set in the Nominal Speed parameter in the Belt

Parameters (page 28) screen. The logical Input “Belt Running” determines the speed

used by the controller. If the input is OFF, the speed is zero. If it is on, then the

“Nominal Speed” is used.

FIRST One tacho is used to measure the speed. It is connected to the Tacho inputs 1A and

1B. See LTI on page 68.

SECOND One tacho is used to measure the speed. It is connected to the Tacho inputs 2A and

2B. See LTI Board on page 68. This setting is normally used in a dual tacho

installation when the first tacho is not working.

BOTH Two tachos are used. The first determines the speed, and the second is used to

detect belt slippage. If a discrepancy between the two tachos is detected, the

General Alarm “Tacos Do Not Comply” is set and the logical output “Belt Slippage”

is turned on. Tacho 1 is still used for determining the speed.

AUTO BYP This mode is similar to BOTH. If there is a discrepancy between the two tachos, the

speed sensing mode is changed to SIMULATOR, and remains there until the

General Alarm “Belt Slippage” has been cleared. This allows for the controller to

keep the feeder operational.

Loading...

Loading...