. A complete Parts List is available at www.MillerWelds.com

OM-261726 Page 15

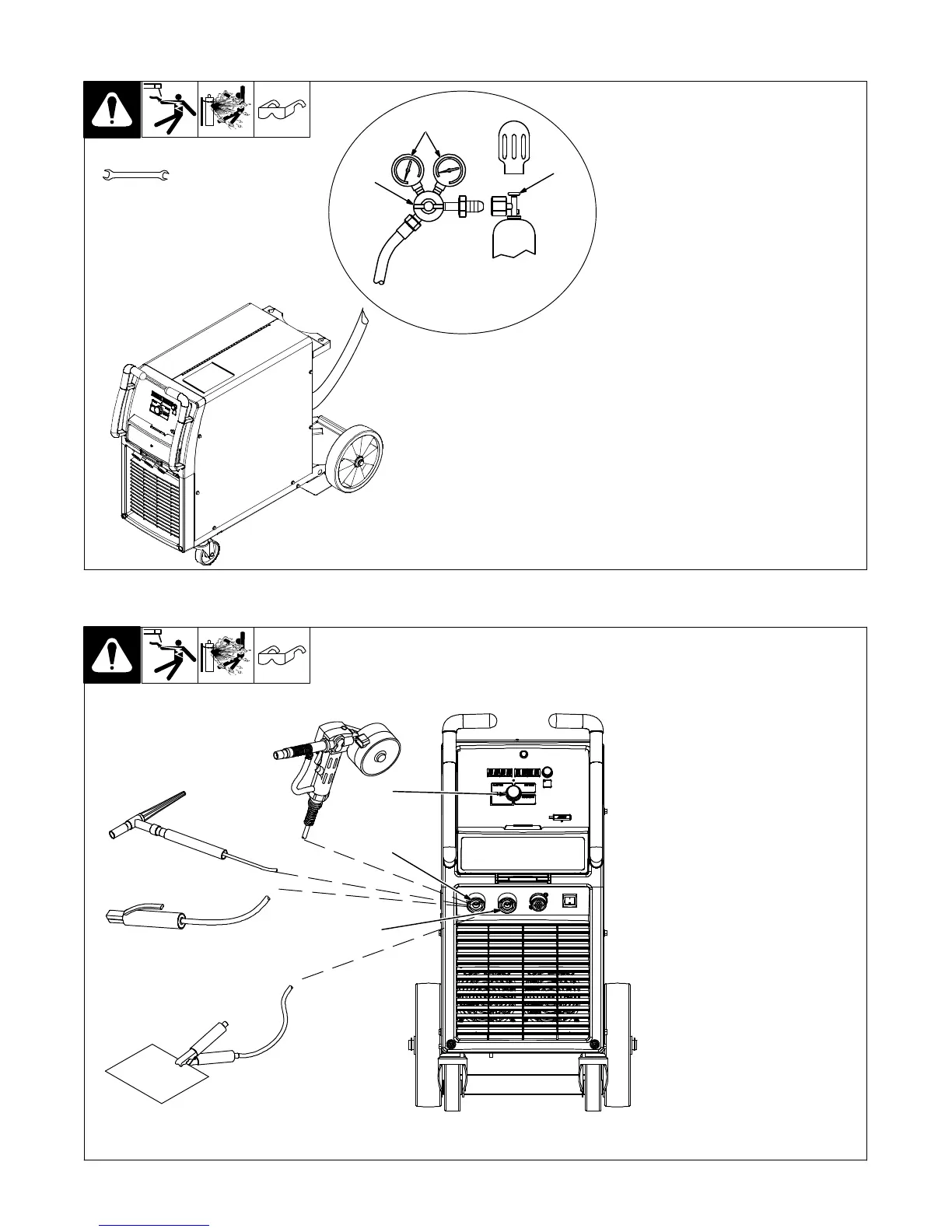

5-3. Shielding Gas Connections

Ref. 805519-A

. Use argon shielding gas for

best performance.

1 Cylinder Valve

Open valve slightly so gas flow

blows dirt from valve. Close valve.

2 Regulator/Flow Gauge

Connect regulator/flow gauge to

gas cylinder. Do not over tighten.

Connect gas hose to gas in fitting.

3 Flow Adjust

Typical flow rate is 20 cfh (cubic feet

per hour).

3

2

5/8, 1-1/8 in.

Tools Needed:

1

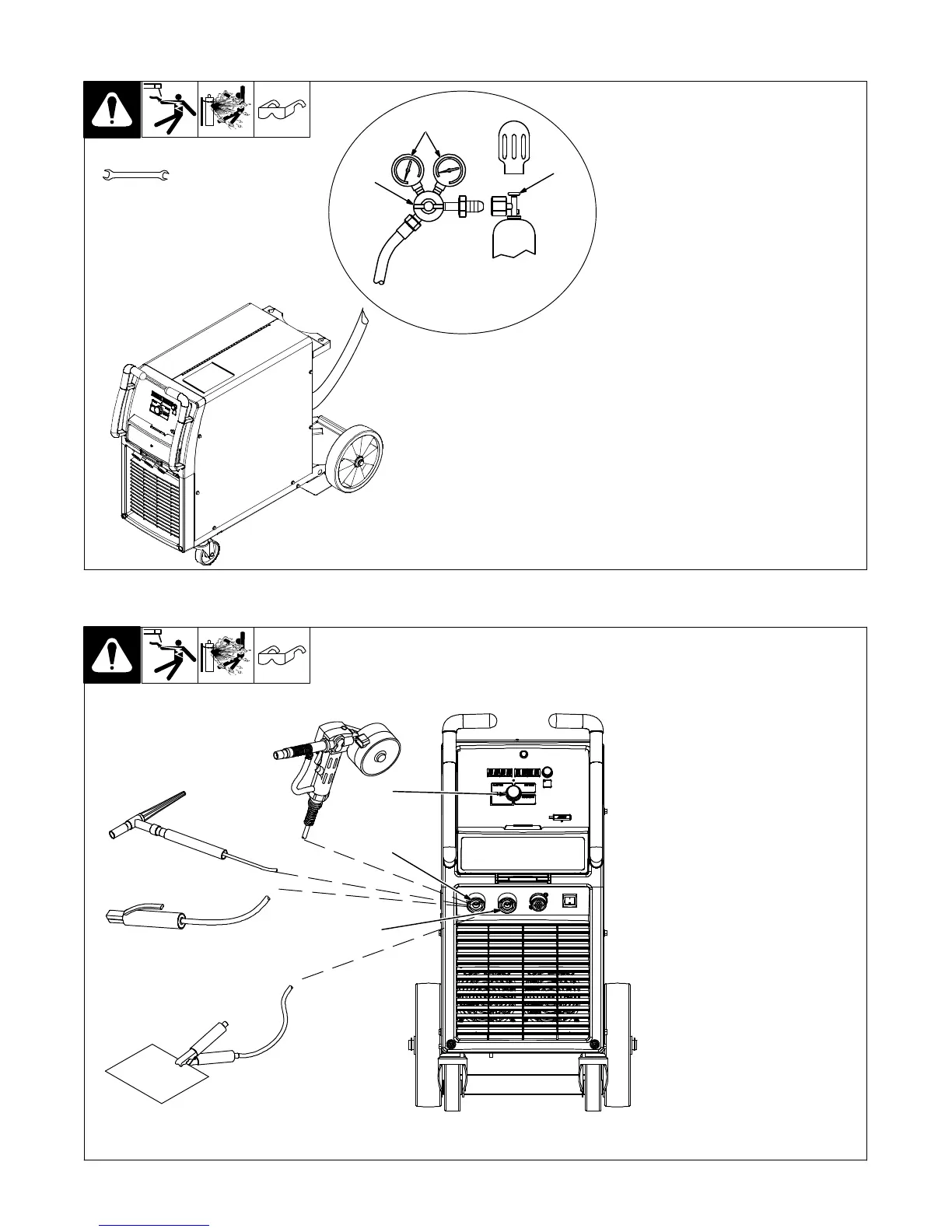

5-4. Weld Output Connections

1 Electrode Output Terminal

For Stick (SMAW) connect elec-

trode holder to this terminal.

For TIG (GTAW), connect torch to

this terminal.

For MIG (GMAW) connect spool

gun to this terminal.

2 Work Terminal

Connect work clamp to this

terminal.

3 Process Selector

Use control to select weld process

(see Section 6-1).

2

1

805521-A

OR

3

OR

Loading...

Loading...