. A complete Parts List is available at www.MillerWelds.com

OM-261726 Page 27

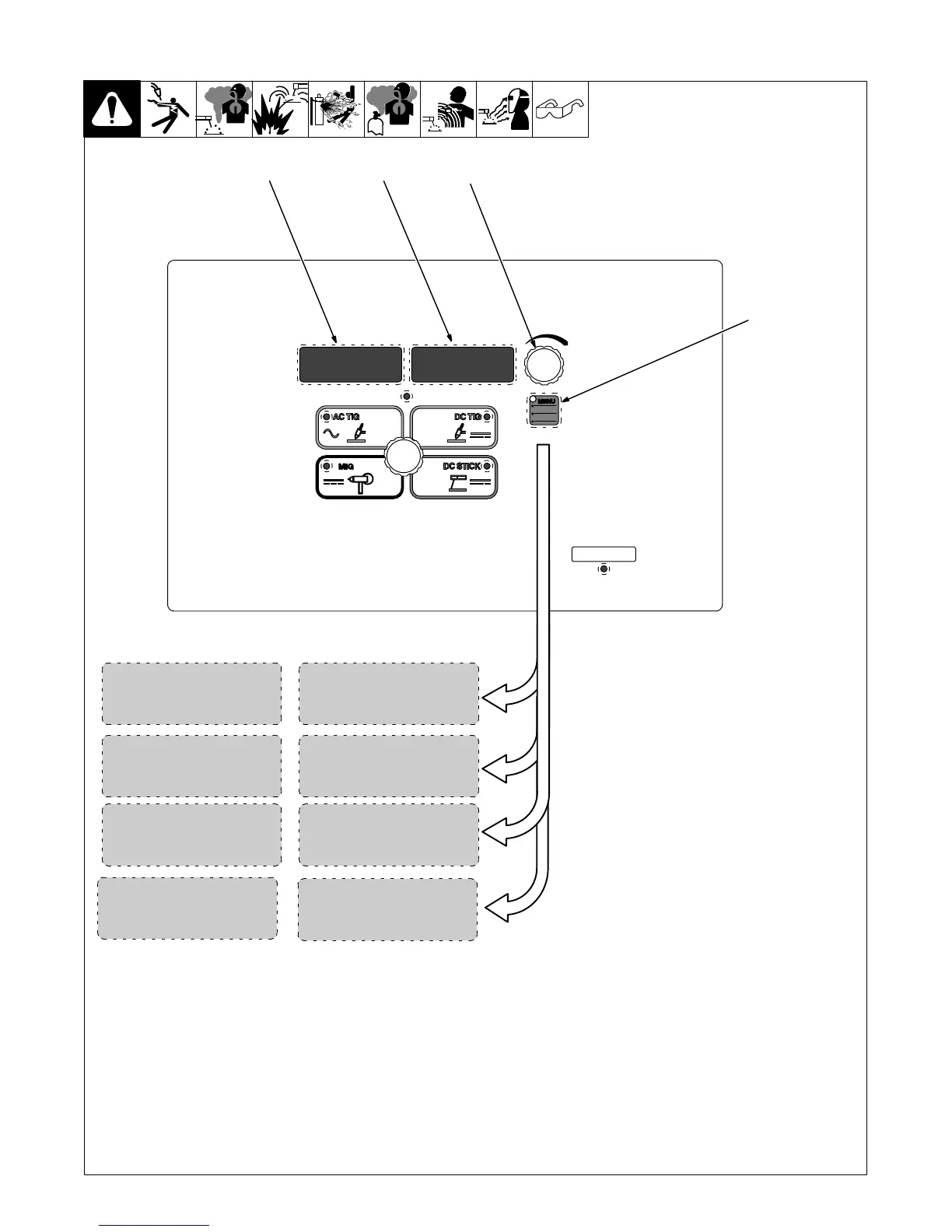

6-6. Accessing User Setup Menu: AC And DC TIG

1 Menu Button

Press and hold Menu button for approxim-

ately two seconds to access machine config-

uration menus. Use Menu button to cycle

through parameters that can be set.

2 Parameter Display

3 Setting Display

4 Encoder

Rotate Encoder to adjust parameter setting.

1

STDRMT

2

3

4

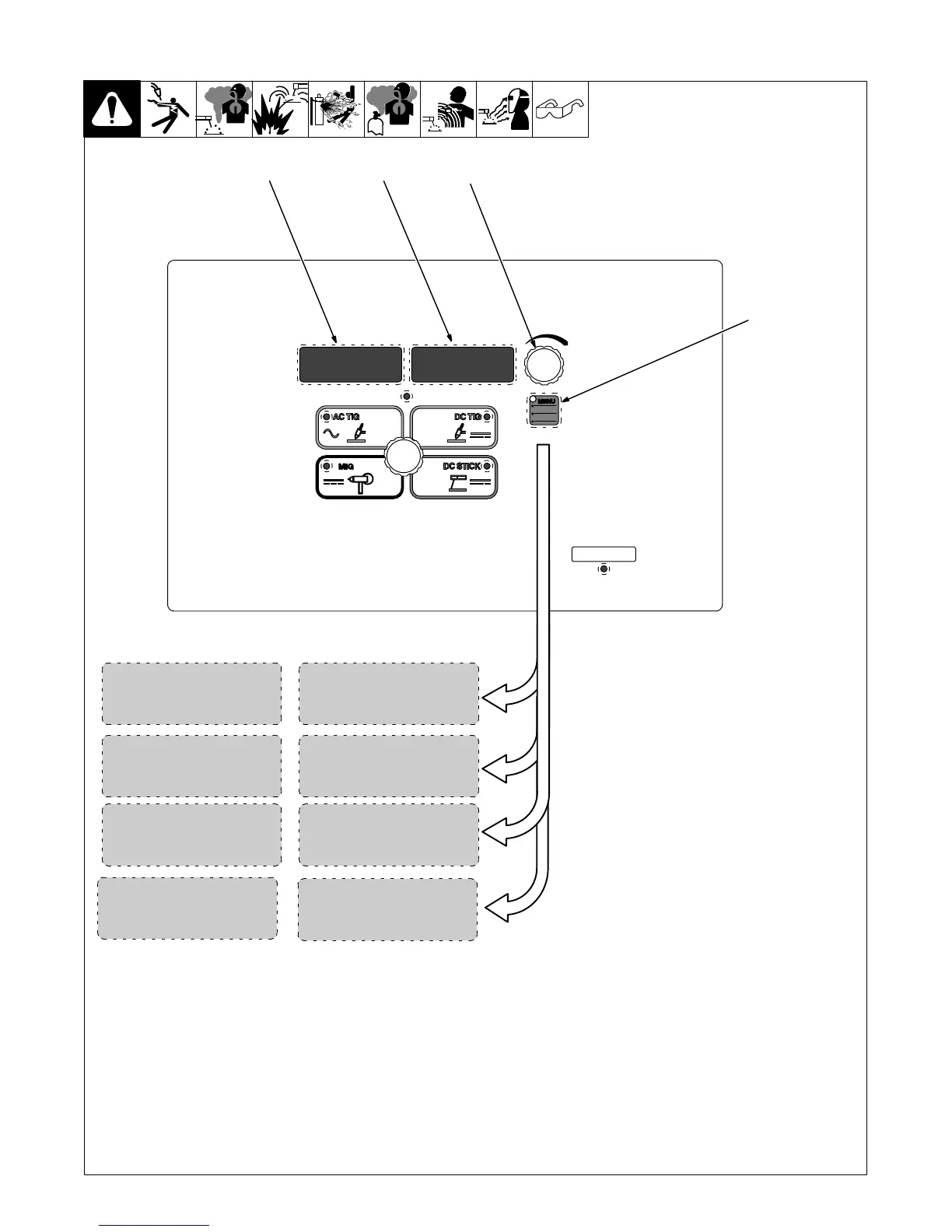

Remote Starting Method Selection:

Remote Starting Options for Lift Arc.

[RMT] [STD]

Standard Remote Control.

[Out] [On]

Output On.

Tungsten Diameter Selection:

Each tungsten size has preset starting

parameters specific to that diameter for op-

timized starting. Range is 0.040 in. to (1/8

in.) and 0.5 mm−3.2 mm.

Post Flow Control Selection:

[POST] [AUTO]

Controls the length of time gas flows after

welding stops. Range is AUTO, OFF − 50T

(seconds). AUTO calculates the time

based on the maximum amperage of each

welding cycle. The minimum time is 8

seconds. Auto = maximum amperage/10.

Arc Starting Method Selection:

[STRT] [HF]

Is a non-contact starting method.

[STRT] [Lift]

Is a contact starting method.

HF

STRT

268890-B

AUTO

POST

MENU

USER

3/32TUNG

Loading...

Loading...