OM-261726 Page 41

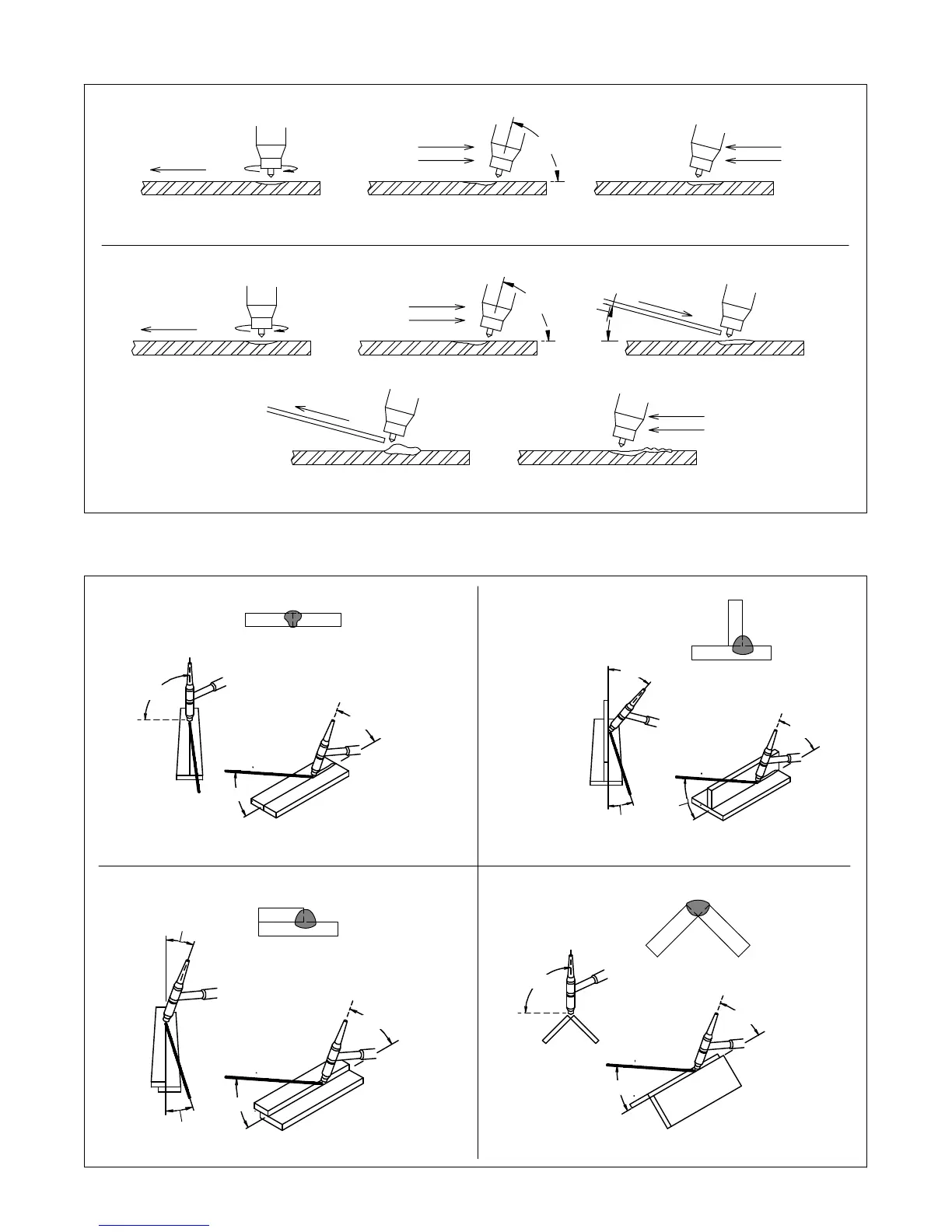

12-2. Torch Movement During Welding

ST-162 002-B

Tungsten Without Filler Rod

Tungsten With Filler Rod

Form pool Tilt torch Move torch to front

of pool. Repeat process.

75°

75°

Welding direction

Form pool Tilt torch Add filler metal

Move torch to front

of pool. Repeat process.

Remove rod

Welding direction

15°

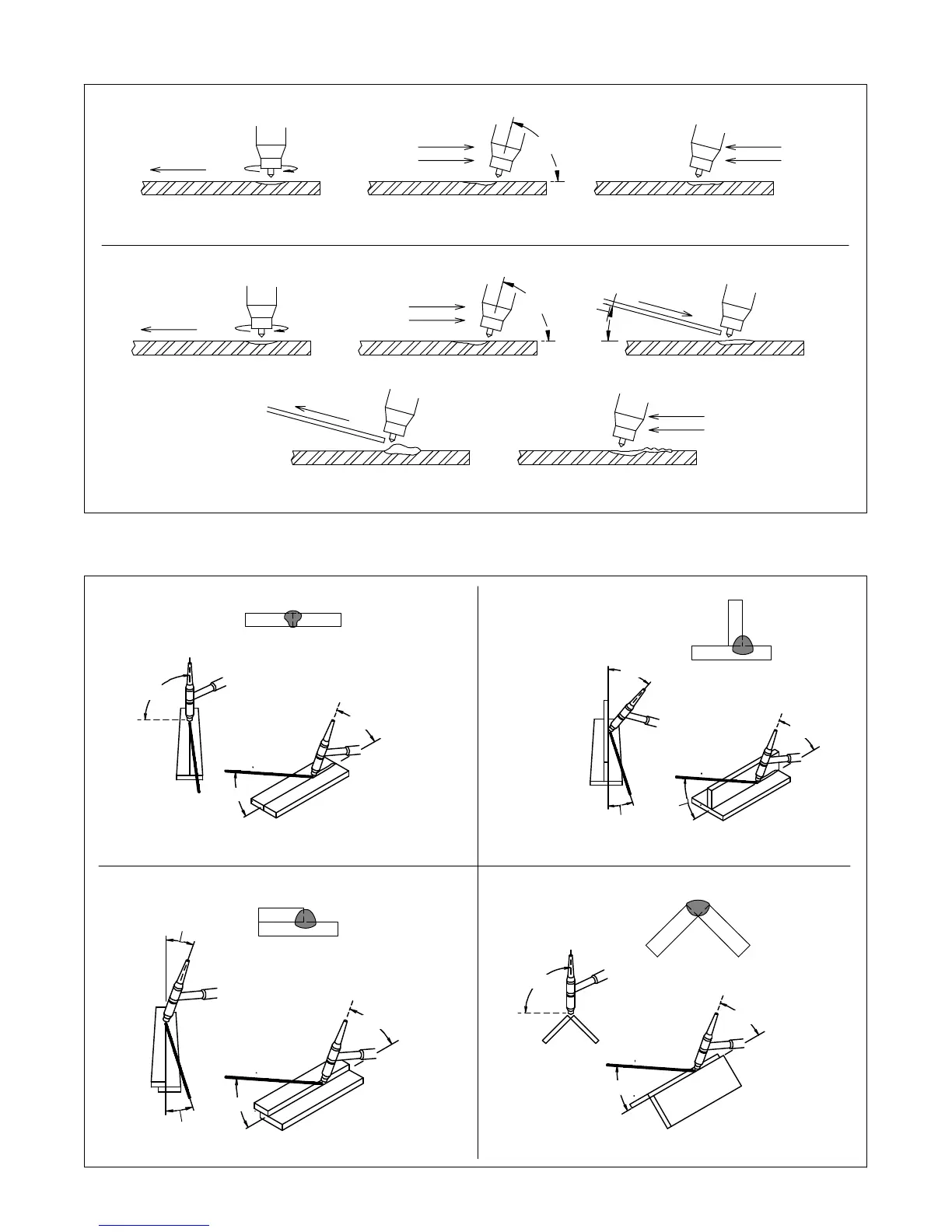

12-3. Positioning Torch Tungsten For Various Weld Joints

ST-162 003 / S-0792

75°

70°

90°

20°

20°

10°

15°

75°

20-40°

30°

15°

75°

90°

15°

Butt Weld And Stringer Bead

“T” Joint

Lap Joint

Corner Joint

Loading...

Loading...