. A complete Parts List is available at www.MillerWelds.com

OM-261726 Page 24

150A

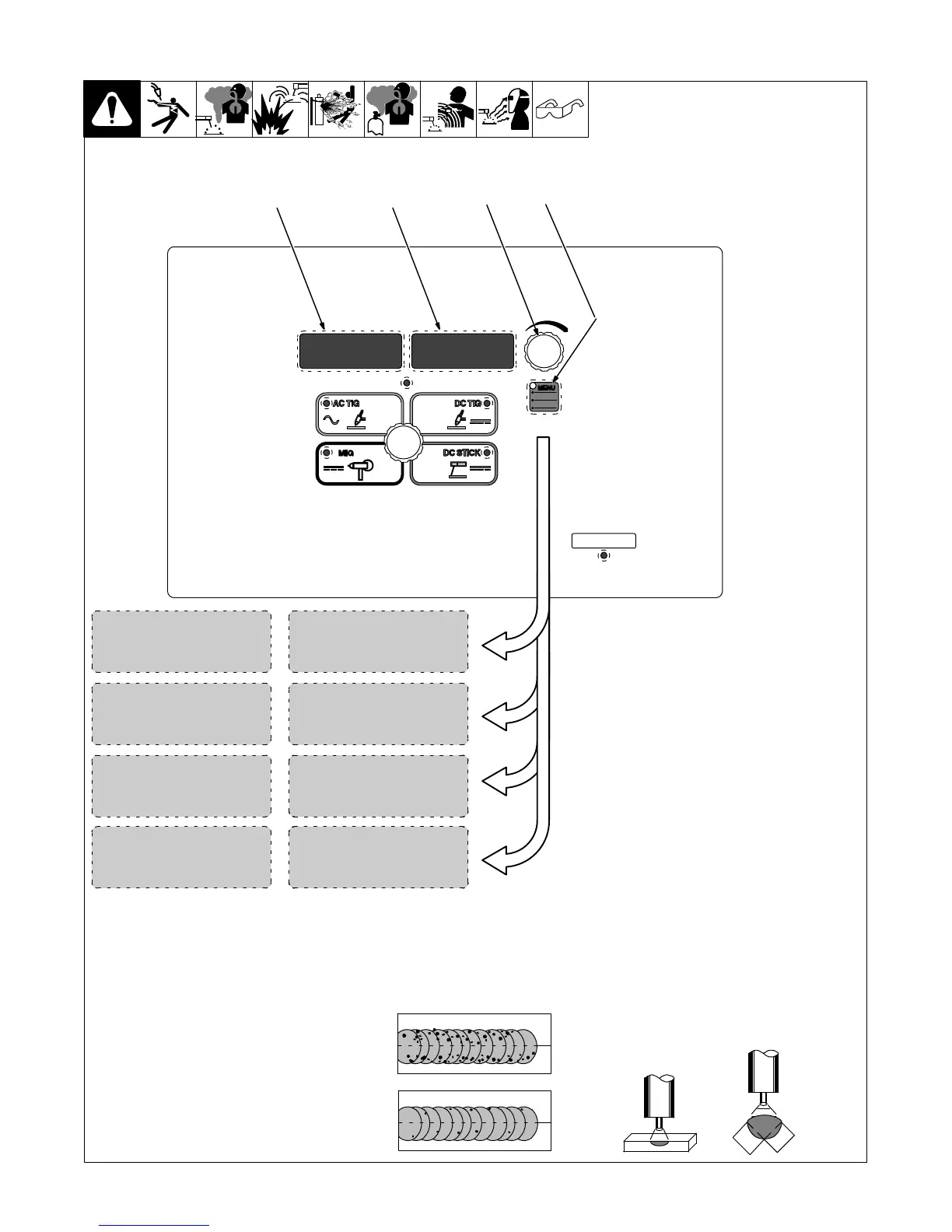

6-2. Accessing Control Panel Menu: AC TIG

268890-B

1 Menu Button

Press Menu button to cycle through

parameters that can be set.

2 Parameter Display

3 Setting Display

4 Encoder

Rotate Encoder to adjust parameter

setting.

1

OFF

75%BAL

234

[BAL] Balance Control:* (% EN)

Controls Oxide Cleaning

Increasing setting reduces oxide cleaning. Range is

60 to 80%. (See tips below)

[PULS] Pulse Control:

Reduces heat input to minimize distortion and in-

crease travel speed. Set PPS (pulses per second).

The range is OFF−50 PPS. The background amper-

age and peak amperage are not adjustable. Back-

ground amperage equals 25% of peak amperage.

Peak amperage time equals 40%.

Amperage Control:

Controls the average AC welding amperage output.

Limits the maximum output of a remote amperage

device.

150A

AC.AV

PPS

120HFREQ

[FREQ] Frequency Control:*

Increasing setting narrows arc width range 60 to 150

Hertz. (See tips below)

*PRO−SET provides PROfessionally de-

veloped SETtings for the weld process.

To use PRO−SET, press the menu button

to display the parameter and adjust the

encoder until PRO−SET flashes on the

display. PRO−SET flashes one time and

reveals the professional setting for the

parameter.

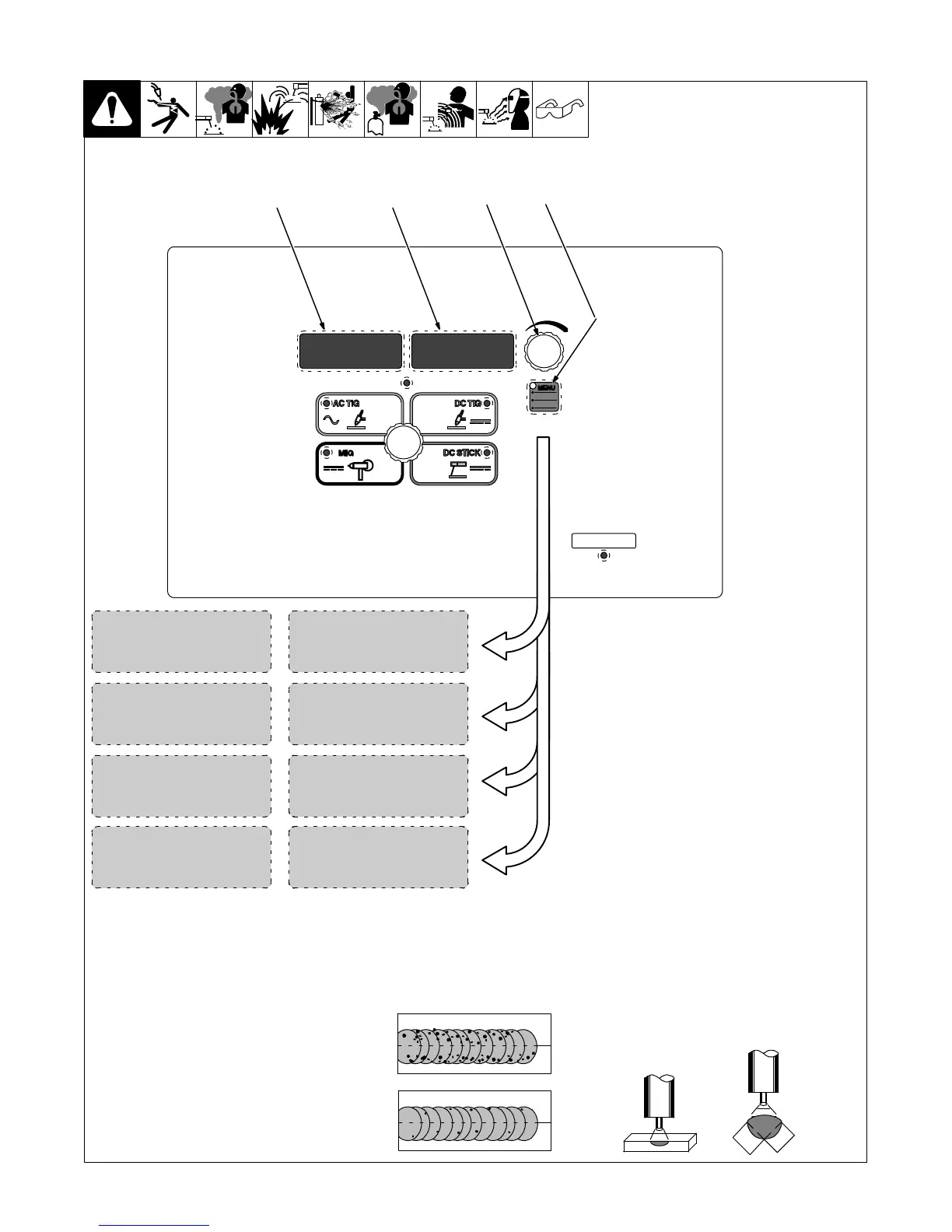

TIP: AC Balance controls the cleaning

action. If floating black spots appear in the

puddle, the balance setting is too high.

Turn the balance down until puddle be-

comes clear.

TIP: AC Frequency controls the width of

the arc cone. For thin fillet welds (less

than 1/4 in.) set the frequency to 120 Hz.

This frequency setting provides a focused

stable arc and produces a narrow weld.

For outside corner or groove welds on

heavy material, a wide weld may be re-

quired. Lower the frequency to between

70 and100 Hz. This frequency setting pro-

duces a wider weld.

Loading...

Loading...