44

Temposonics

®

R-Series SSI

Operation Manual

Temposonics

®

R-Series SSI

Operation Manual

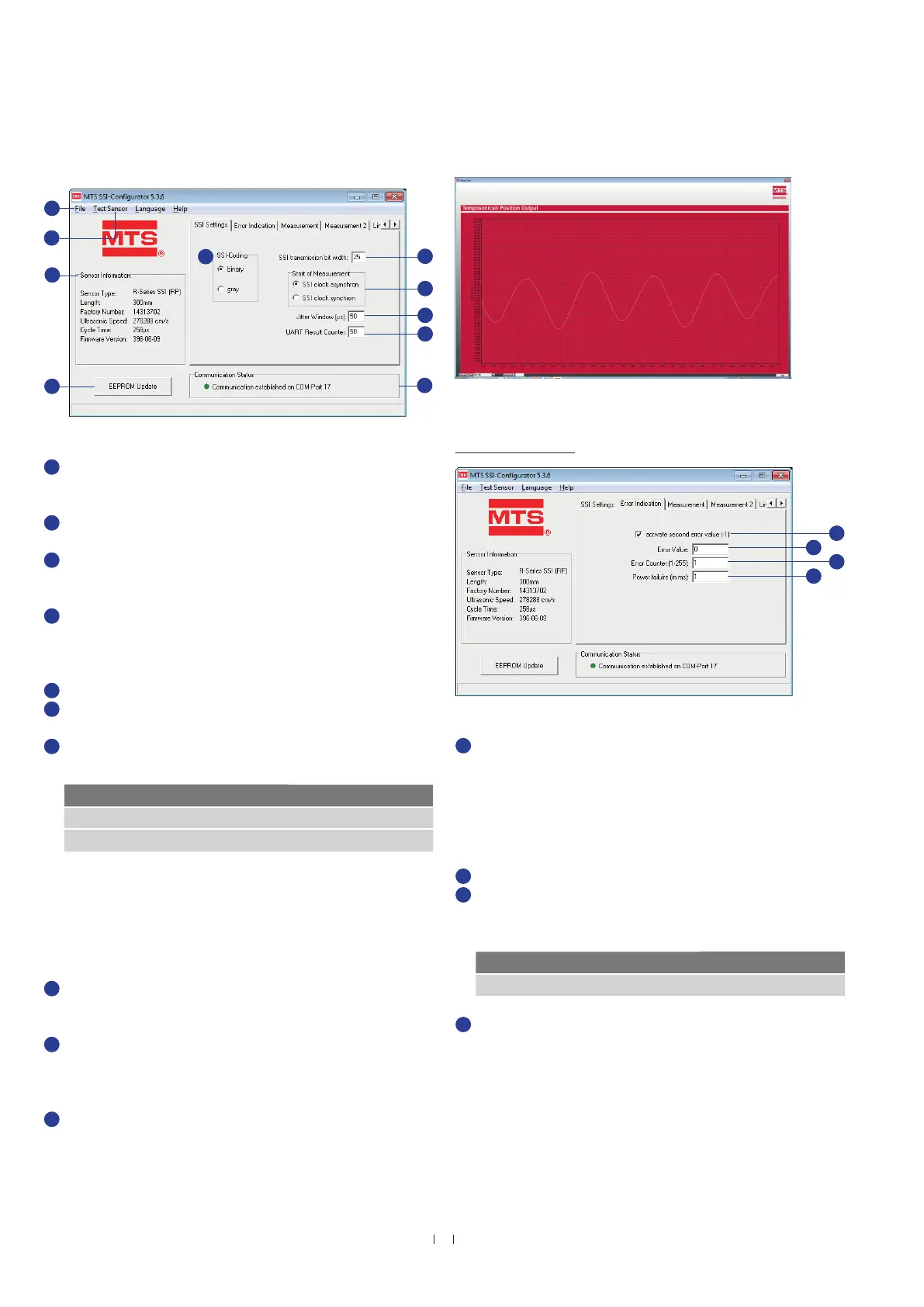

Fig. 57: MTS SSI-Configurator, SSI Settings

Fig. 58: Graphical display of position values via Test Sensor

Fig. 59: MTS SSI-Configurator, Error Indication

1

In the File menu, you can save the sensor configuration on

hard disk, print it out or load it into the sensor. Moreover, this

menu permits returning to the factory setting.

2

Via Test Sensor the position of the magnet is displayed graphically.

(Fig. 58).

3

Frame Sensor Information contains the invariable sensor

parameters, which are read in automatically when connecting the

sensor.

4

Click on EEPROM Update to send and store altered parameters

(highlighted with a blue background) permanently in the sensor.

Subsequently, the stored values are displayed again with a white

background.

5

Use the option box binary or gray to determine the SSI coding.

6

In this field you can set the SSI transmission bit width for the

position output.

7

Use the option box SSI clock asynchron and SSI clock synchron

to change the start of measurement.

In asynchronous mode the sensor starts measuring and provides

the position independent of the PLC.

In synchronous mode 1 the output of the position of the

Temposonics

®

SSI sensor is matched to the data request

cycle of the controller. The contouring error complies with the cycle

time of the stroke length.

8

The jitter specifies the time interval between the start of measuring

and the SSI clock, which is given by the PLC (for “SSI clock

synchron”).

9

Via

UART Result Counter you define a time interval for the function

Test Sensor to send a position value Fig. 58 (graphical presentation

of position values).

Example: If you choose “50” in the field UART

Result Counter, each 50. measurement will be displayed.

10

Communication Status indicates that the sensor is connected

successfully.

11

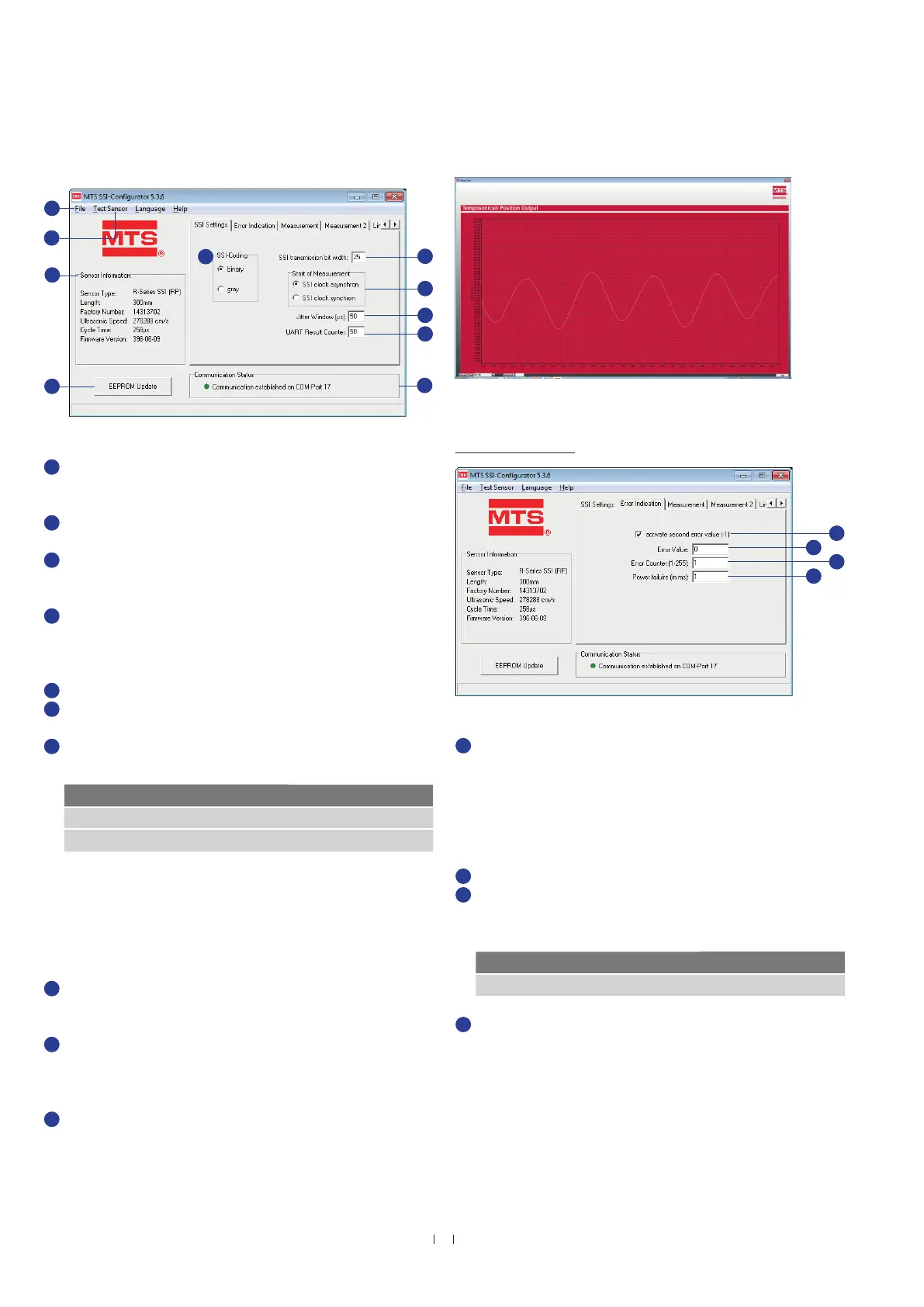

If the check box activate second error value (-1) is active, an error

value of “−1” is output if the sensor is used with more magnets as

specified before. If the check box is not active and the sensor is

used with more magnets as specified before, the value which was

defined in field Error Value will be displayed. The Error Value will

also display if the sensor is used with less magnets as determined

before.

12

In the case of failure the sensor transmits the Error Value.

13

Use the field Error Counter to determine how often in the case of

failure (1…255 times) the old measurement value will be repeated,

before the Error Value will be displayed.

14

In this field you can define a period (1…100 ms), during which the

power supply of the sensor can be fallen short of, without the Error

Value to display. Set the value to “0” to deactivate the function

Power failure (in ms).

MTS SSI-Configurator user interface

MTS SSI-Configurator R-Series order code

Error counter complies with Error delay

10

6

MTS SSI-Configurator R-Series order code

SSI clock asynchron complies with Asynchronous mode

SSI clock synchron complies with Synchronous mode 1

2

5

8

9

7

Tab “Error Indication”

11

12

13

14

1

3

4

Loading...

Loading...