4. Slide the enclosure through the panel cutout

untilitsangecontactsthepanel.

5. Insertmountingscrewsthroughtheange

mounting holes and tightly secure.

6. Reconnect all panel cable(s)/wire(s) and re-

secure the front panel using 6-32 x 3/8”

screws provided.

Caution: Do not use 6-32 x 1/2” used on “picture

frame” front panel models.

C. OEM MECHANICAL INSTALLATION

This section provides the recommended procedures for properly

installing the OEM 750 Series II Conductivity/Resistivity Monitor/

controller.

NOTE: Mounting of the OEM monitor/controller circuit board

is left up to the OEM. It is recommended that the following be

noted and observed.

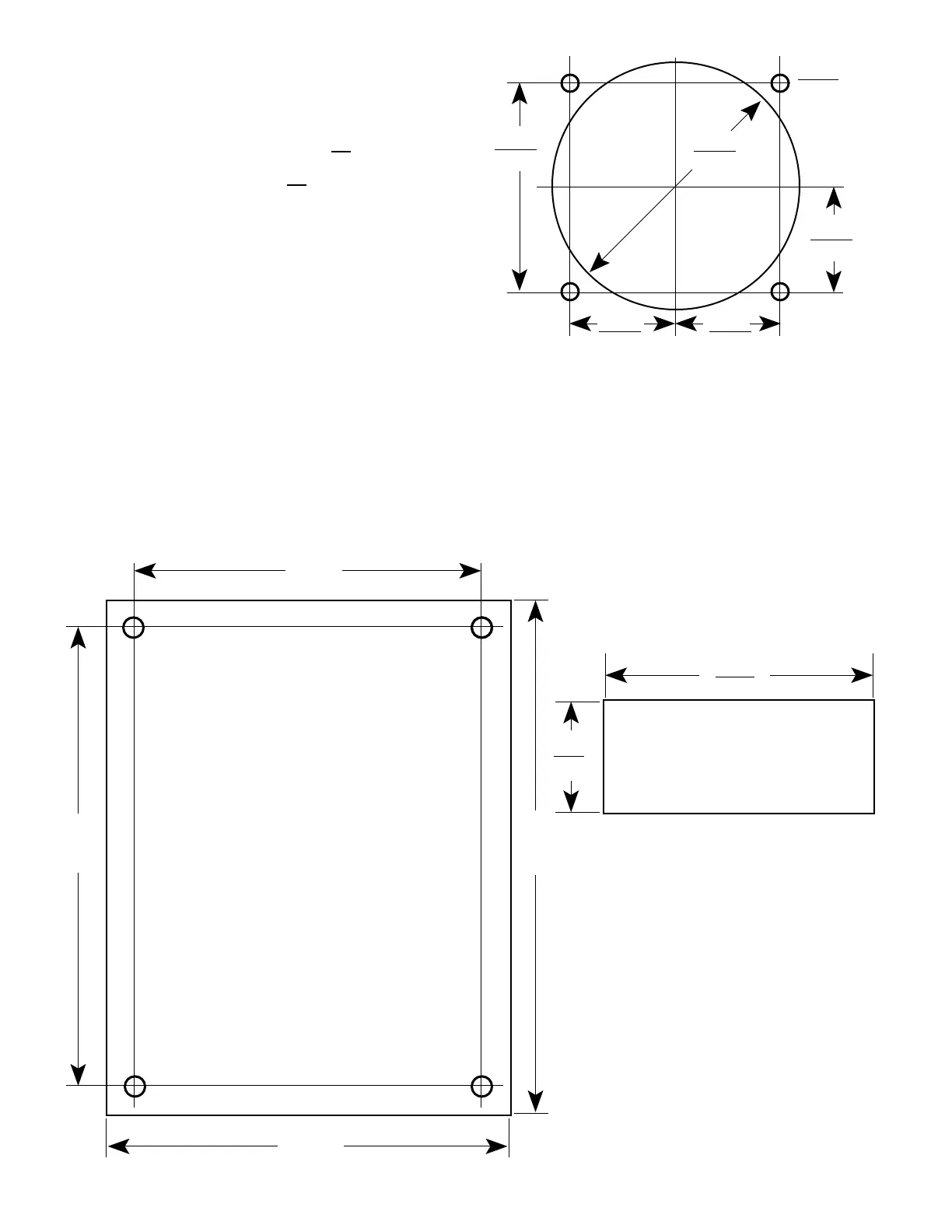

1. CIRCUIT BOARD

Total height of CB is 1.40” (36mm).

The circuit board has four (4) .175” (4.4 mm) holes for mount-

ing. The centers are 3.10” (78.7 mm) x 4.10” (104.1 mm) see

gureII.C.1.CBmustbemountedonatleast.250”(6.35mm)

standoffs to prevent shorting to metal chassis (standoffs user

supplied). CB must be mounted in a clean and dry environment.

Allow working room for inserting wires, testing and calibration.

Indicator lights and switches require 1/4” (6.35mm) holes.

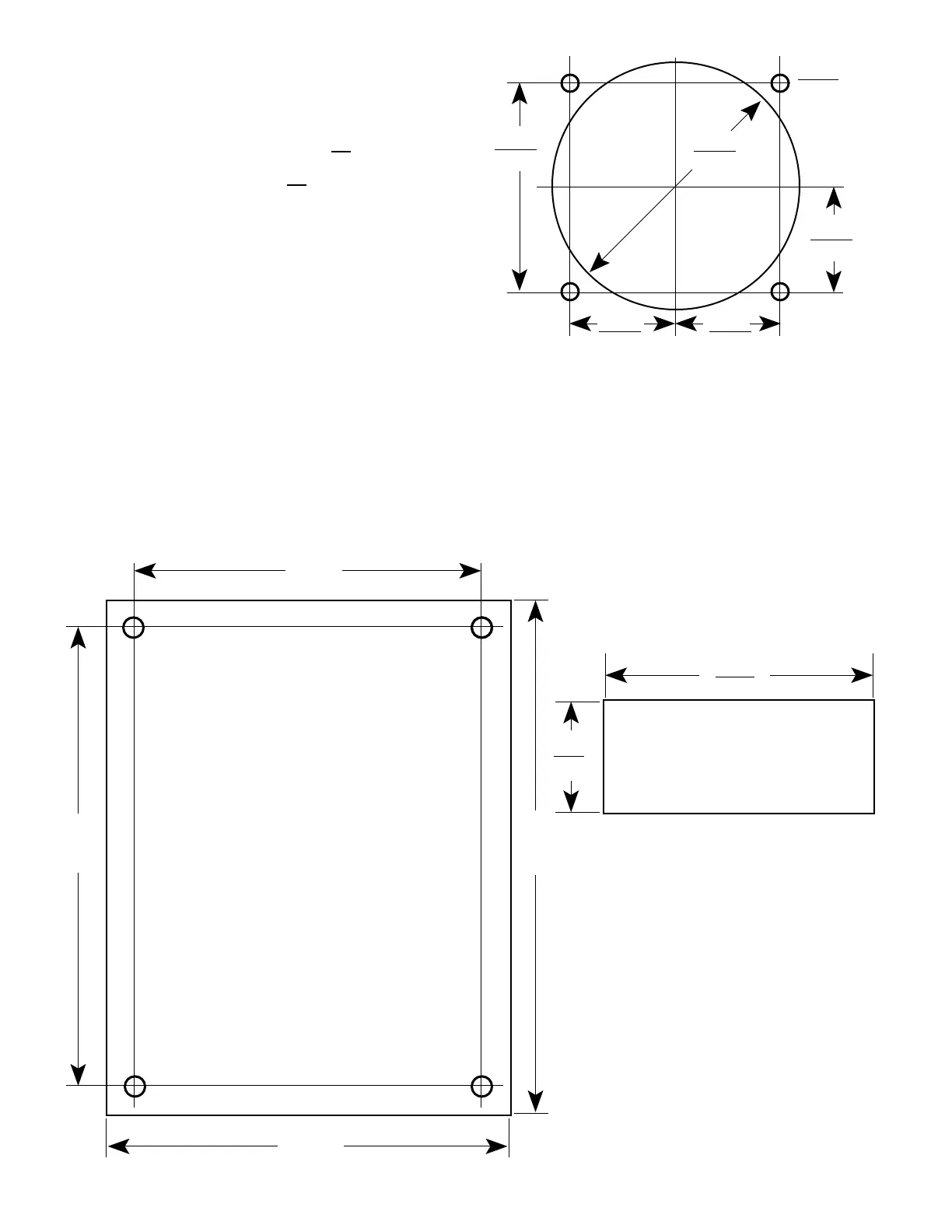

2. METER MOVEMENT

RefertogureII.C.2fordimensions.

1. Cut opening in user panel.

2. Drill four (4) holes at locations as shown.

3. Install meter movement using supplied

hardware.

4.585

3.600

4.100

(78.74)

Figure 11.C.1

10

2.218 Dia.

.940

1.880

.940

.940

(23.88)

(3.125)

56.34

Analog Meter Hole Pattern

Figure II.C.2

2.390

(60.71)

.980

DIGITAL DISPLAY CUTOUT

PATTERN

Figure II.C.3

3. DIGITAL DISPLAY

RefertogureII.C.3fordimensions.

1. Cut opening in user panel

2. Install LCD with brackets

supplied.

Loading...

Loading...