24

FATAL TO PERSONNEL. ONLY QUALIFIED PERSON-

NEL SHOULD INSTALL ELECTRICAL EQUIPMENT.

Physical

If the front panel has all ready been removed from the enclosure

skip to #3.

1. Using a standard slot screwdriver remove the four (4)

screws on the front panel.

2. Carefully wiggle the front panel to loosen and pull gently

toward you. Do not pull more than about 8 inches/

20CM or you could damage the wiring harness.

3. Turn the front panel around so that the back side is

facing you.

4. Using a standard slot screwdriver remove the four (4)

screws holding the plastic display retainer plate to the

front panel. When the screws have been removed, the

plastic display retainer plate and the display will be free

from the front panel.

5. Set front panel down or carefully allow to hang from the

harness. Do not drop as the harness connector will pull

out allowing the front panel to fall.

6. While holding the display and the plastic display retainer

plate, carefully remove the display harness connector.

Do not drop the display. Remove and discard the plastic

display retainer plate.

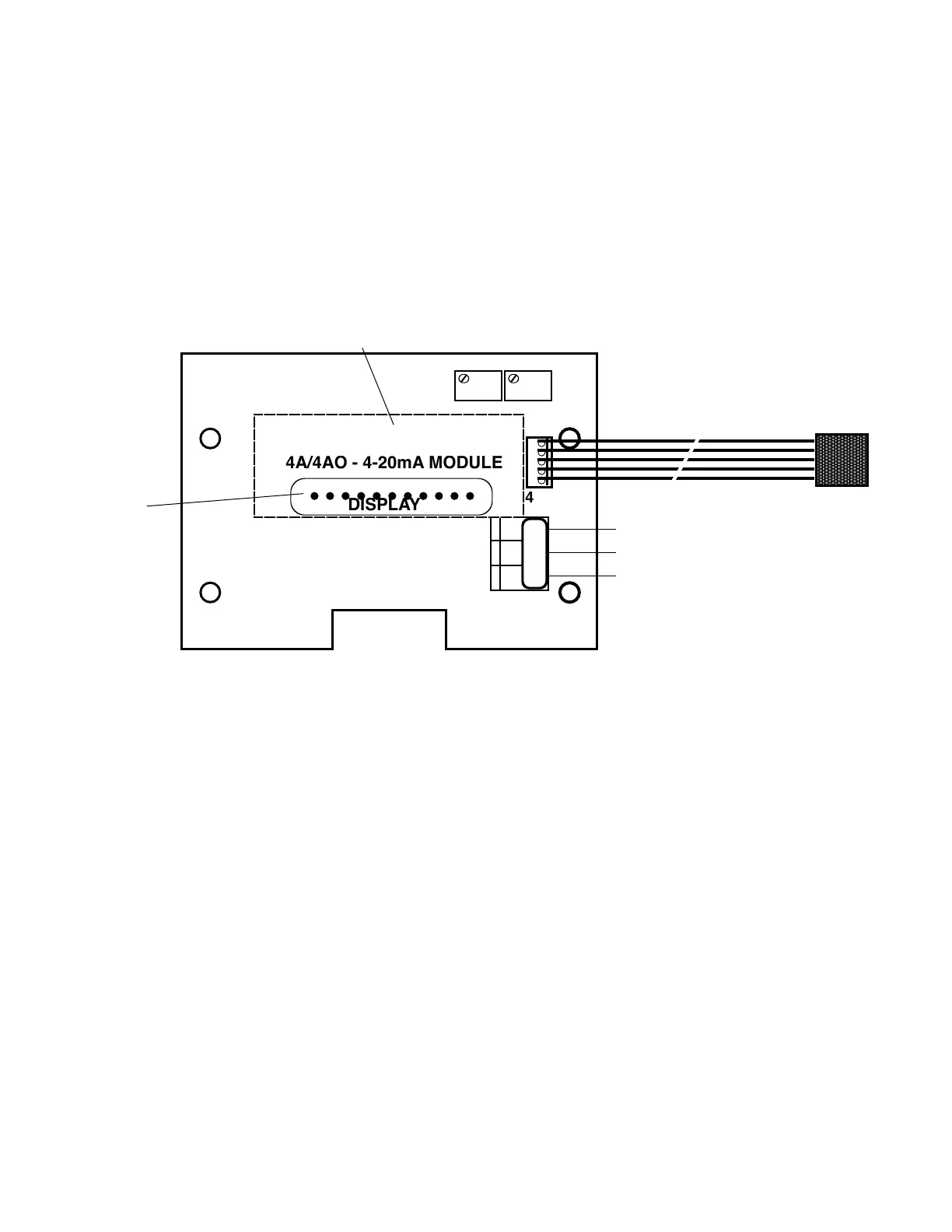

7. While still holding the display in the palm of your hand,

set the 4-20 Module over it with the display pins

protruding through the center opening as shown in

gureIII.B.3.

8. Reconnect the harness to the display as shown in

gureIII.B.3.

9. While holding the front panel, align the display to the

opening while at the same time align the 4-20 Module

mounting holes to the front panel.

10. Reinstall the four (4) screws and tighten.

Electrical

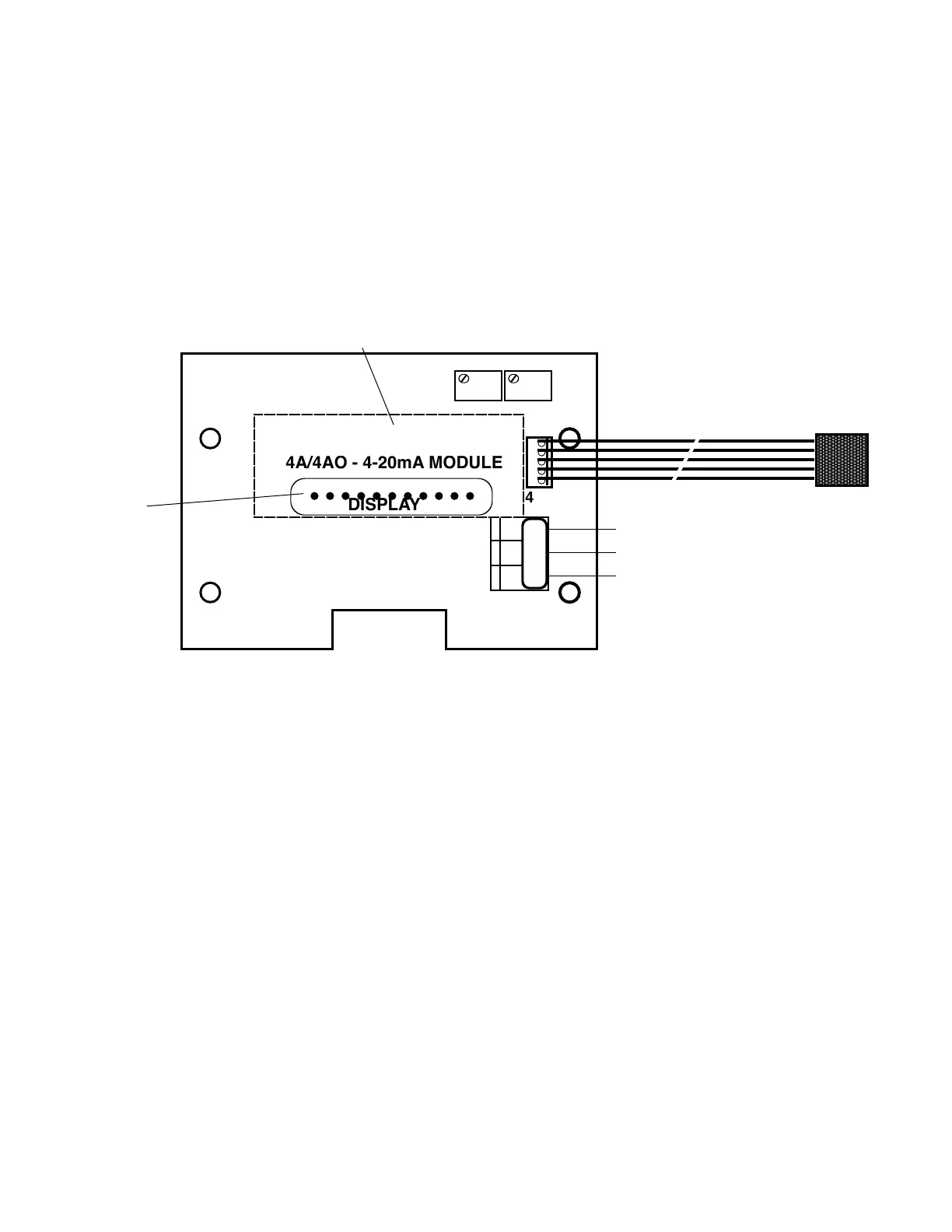

1. Connectthe4-20Module(ve)5wireharnesstothe

main circuit board at the location next to the display

harness marked “4-20”asshowningureIII.B.4.

2. Connect the signal and power wires as required, as

showninguresIII.B.1.&III.B.2.Thisassumesyou

have already connected the other end of the wires as

required.

a. Place the remote interface cable and user supplied

watertightcablerestraintintotheenclosure’s

appropriate access hole.

b. Neatly connect the signal cable wires to the

Monitor’sappropriateconnectorsasshownin

gureIII.B.3.

3. To test, turn power ON.

4. Press the Full Scale Test switch and monitor the output

atyourremotesite,orwithaDVMsettoDCmilliamps.

AttachtheDVMtotheoutputconnectorsperyour

requirements, i.e. self-powered or remote-powered, see

guresIII.B.1.&III.B.2.Ifthe4Amoduleisconnected

properly it will indicate 20mA.

5. Turn power OFF.

6. Carefullyreinstallthefrontpanel,bottomrst,ensureno

wires have been pinched between enclosure and front

panel.

7. Reinstall the four (4) screws and tighten.

8. To operate, turn power ON.

3. RECALIBRATION

The 4-20 Module was calibrated at the factory; however, if you

wish to check the calibration the following procedure will help

you to accomplish this task. Exercise caution while performing

this procedure.

Requirements; aDVMsettoDCmilliamps,atweakerorsmall

standard slot screwdriver.

This procedure assumes the front panel is removed.

For Resistivity models, please follow special notes (*)

1. If sensor is connected, disconnect sensor wires from

sensor terminal block. (* For Resistivity models,

connect the sensor wires (red, green, & neutral)

into the sensor terminal block. Use a jumper to

bridge the black and white terminals together.)

2. AttachtheDVMtotheoutputconnectorsperyour

requirements, i.e. self-powered or remote-powered,

seegureIII.B.5.

3. FORRESISTIVITYONLY:Addjumperbetween

Black(BK) and White(WT) connectors, see Figure III.B.4.

For Conductivity, go to step 4.

4. Turn power ON, with the front panel meter/display at

ZERO,theDVMshouldindicate4milliamps.

DISPLAY IS ON BACK SIDE OF 4-20 MODULE

RECONNECT

DISPLAY

CONNECTOR

HERE

SO PO PI

Loading...

Loading...