16 – ENGLISH

ELECTRICAL CONNECTIONS

Terminals Description

Stop

Input for devices that through their intervention trigger the immediate stoppage of the current manoeuvre followed

by a brief reversal. NO (normally open) contacts, NC (normally closed) contacts or devices with 8.2 kΩ xed

resistor output, such as sensitive edges, can be connected to this input. Each device connected to this input

will be individually recognised by the control unit during the learning phase (see “Device learning” paragraph).

During this phase, if the control unit detects any variation with respect to the learned status, it triggers a STOP.

One or more devices, even different from one another, can be connected to this input: any number of NO inputs in

parallel; any number of NC inputs in series; 2 devices with 8.2 kΩ xed resistor output in parallel. If there are more

than 2 devices, they must all be connected in cascade mode with a single 8.2 kΩ terminating resistor; 2 NO and

NC devices in parallel, putting an 8.2 kΩ resistor in series with the NC contact (this also allows for combining 3

devices: NO, NC and 8.2 kΩ).

SbS

Input for a NO (normally open) button, for sending commands in step-by-step mode.

Open

Input for command devices that trigger the opening manoeuvre only, when they intervene. NO (normally open)

contacts can be connected to this input.

Close

Input for command devices that trigger the closing manoeuvre only, when they intervene. NO (normally open)

contacts can be connected to this input.

FINAL CHECKS AND START-UP

5

5 FINAL CHECKS AND START-UP

It is advisable to position the leaf approximately halfway along its

path before starting the automation check and start-up phases,

so that the leaf is free to open and close.

5.1 POWER SUPPLY CONNECTION

a

The power supply connections must only be made

by qualied and experienced personnel possessing

the necessary requirements and in full conformity

to the laws, regulations and standards in force.

As soon as the product is powered, a few simple checks should

be carried out:

1. check that the “BlueBUS” LED ashes regularly with one

ash per second

2. check that the LEDs on the photocells (both the TX and

RX) also ash; the type of ashing is irrelevant, since it

depends on other factors

3. check that the warning light connected to the FLASH

output is off.

If the above conditions are not satised, immediately switch

off the power supply to the control unit and carefully check the

electrical connections.

Further useful information on searching and diagnosing faults is

included in the “TROUBLESHOOTING GUIDE” chapter.

5.2 DEVICE LEARNING

After the initial start-up, the control unit must recognise the

devices connected to the “Bluebus” and “Stop” inputs.

l

The learning phase must be carried out even if no

device is connected to the control unit.

The control unit can individually recognise the various devices

connected, thanks to the learning procedure, and detect

possible anomalies.

For this to occur, the device learning procedure must be carried

out whenever a device is added or removed.

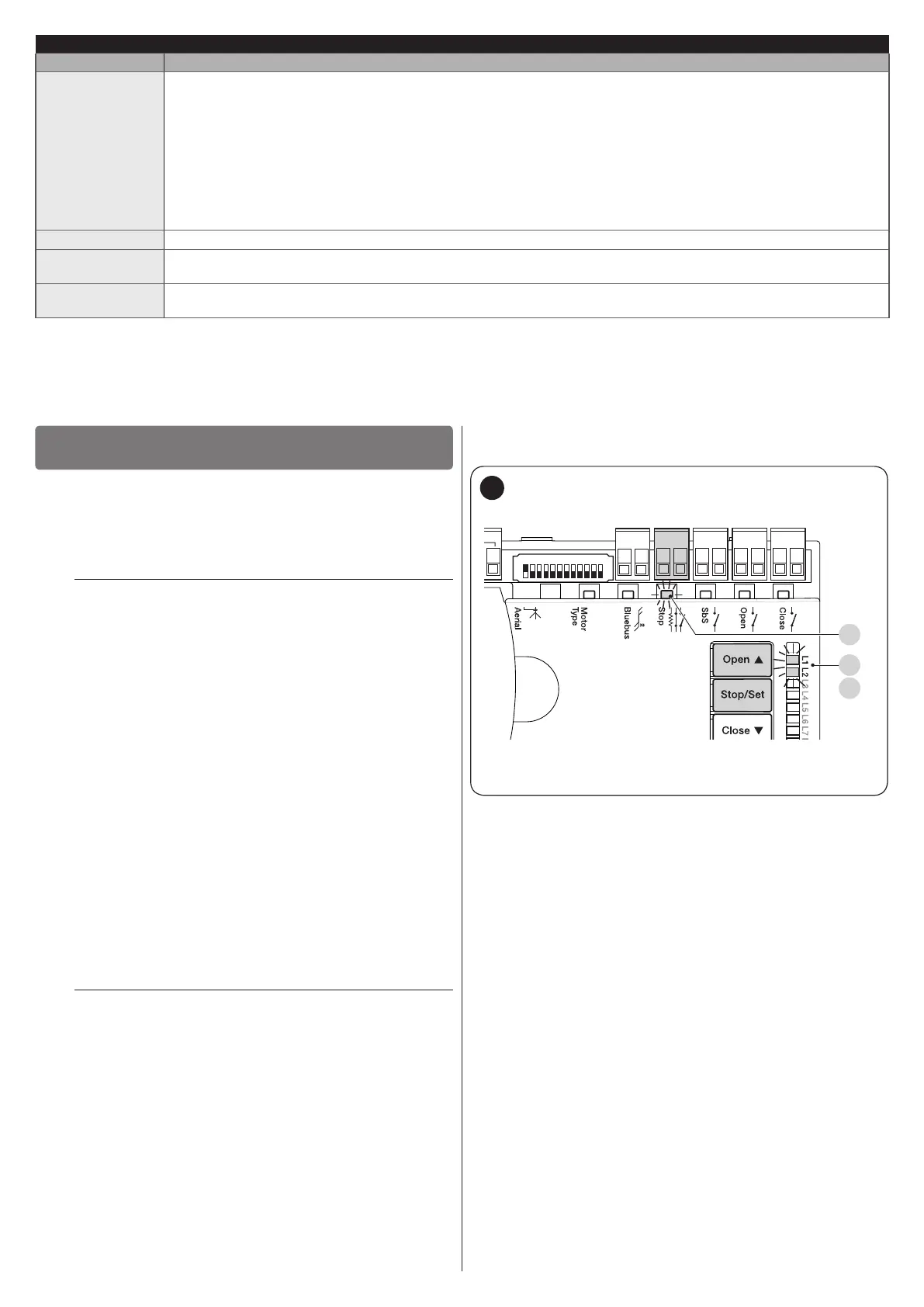

CloseOpenSbSStop

Bluebus

1 2 3 4 5 6 7 8 9

10 11 12

L1

L2

S

42

LEDs “L1” and “L2” on the control unit (“Figure 42”) emit

some slow ashes to signal that the learning procedure must

be carried out.

To do this:

1. simultaneously press and hold the

f

and

g

buttons

2. release the buttons when LEDs “L1” and “L2” start

ashing quickly (after roughly 3 seconds)

3. wait a few seconds until the control unit has completed the

device learning phase

4. once this phase terminates, the “Stop” (S) LED must be lit

and LEDs “L1” and “L2” must switch off (LEDs “L3” and

“L4” could start ashing).

Loading...

Loading...