20 – ENGLISH

5.6 CONNECTING OTHER DEVICES TO THE

CONTROL UNIT

In any additional devices belonging to the system (e.g.

transponder card reader, light for the key selector, etc.) must

be powered, they can be connected to the control unit using

terminals “SbS (positive)” and “Stop (negative)” (“Figure 41”).

The power supply voltage is 24 Vc with a maximum available

current of 200 mA.

l

The voltage available at the “SbS” and “STOP”

terminals remains even when the “Stand-by”

function is enabled on the board.

TESTING AND COMMISSIONING

6

6 TESTING AND COMMISSIONING

These are the most important phases of the automation’s

construction, as they ensure maximum safety of the system. The

test can also be used to periodically verify the devices making

up the automation.

m

Testing and commissioning of the automation must

be performed by skilled and qualied personnel,

who are responsible for the tests required to

verify the solutions adopted according to the risks

present, and for ensuring that all legal provisions,

standards and regulations are met, in particular

all the requirements of the EN 12445 standard,

which denes the test methods for checking gate

automations.

The additional devices must undergo specic testing, both in

terms of their functions and their proper interaction with the

control unit. Refer to the instruction manuals of the individual

devices.

6.1 TESTING

To run the test:

1. verify that all the instructions stated in the “GENERAL

SAFETY WARNINGS AND PRECAUTIONS” chapter

have been strictly observed

2. unlock the gearmotor as indicated in the “Manually

unlocking and locking the gearmotor” paragraph

3. make sure that the leaf can be moved manually during

both the opening and closing phases with a force not

exceeding 390N (roughly 40 kg)

4. lock the gearmotor

5. using the control devices (transmitter, control button,

key selector, etc.), test the gate’s opening, closing and

stoppage movements to make sure that the leaves move

as intended. Several tests should be carried out to assess

the movement of the leaves and detect any defects in

the installation and adjustment, besides any points of

excessive friction

6. check, one-by-one, that all safety devices mounted on the

system (photocells, sensitive edges, etc.) work properly.

Each time a device intervenes, the “Bluebus” LED on

the control unit will emit two faster ashes to conrm the

recognition

7. if potentially dangerous situations due to the movement

of the leaves have been prevented by limiting the impact

force, the latter must be measured according to the EN

12445 standard and, if the “motor force” control is used to

aid the system in reducing the impact force, it is necessary

to test various adjustments to nd the one that gives the

best results.

6.2 COMMISSIONING

a

Commissioning can only be performed after all

testing phases have been successfully completed.

a

Before commissioning the automation, ensure that

the owner is properly informed of all residual risks

and hazards.

a

The gate cannot be commissioned partially or under

“temporary” conditions.

To commission the automation:

1. compile the automation’s technical le, which must

include the following documents: overall drawing of the

automation, wiring diagram, risk assessment and relative

solutions adopted, the manufacturer’s declaration of

conformity for all devices used and the declaration of

conformity compiled by the installer

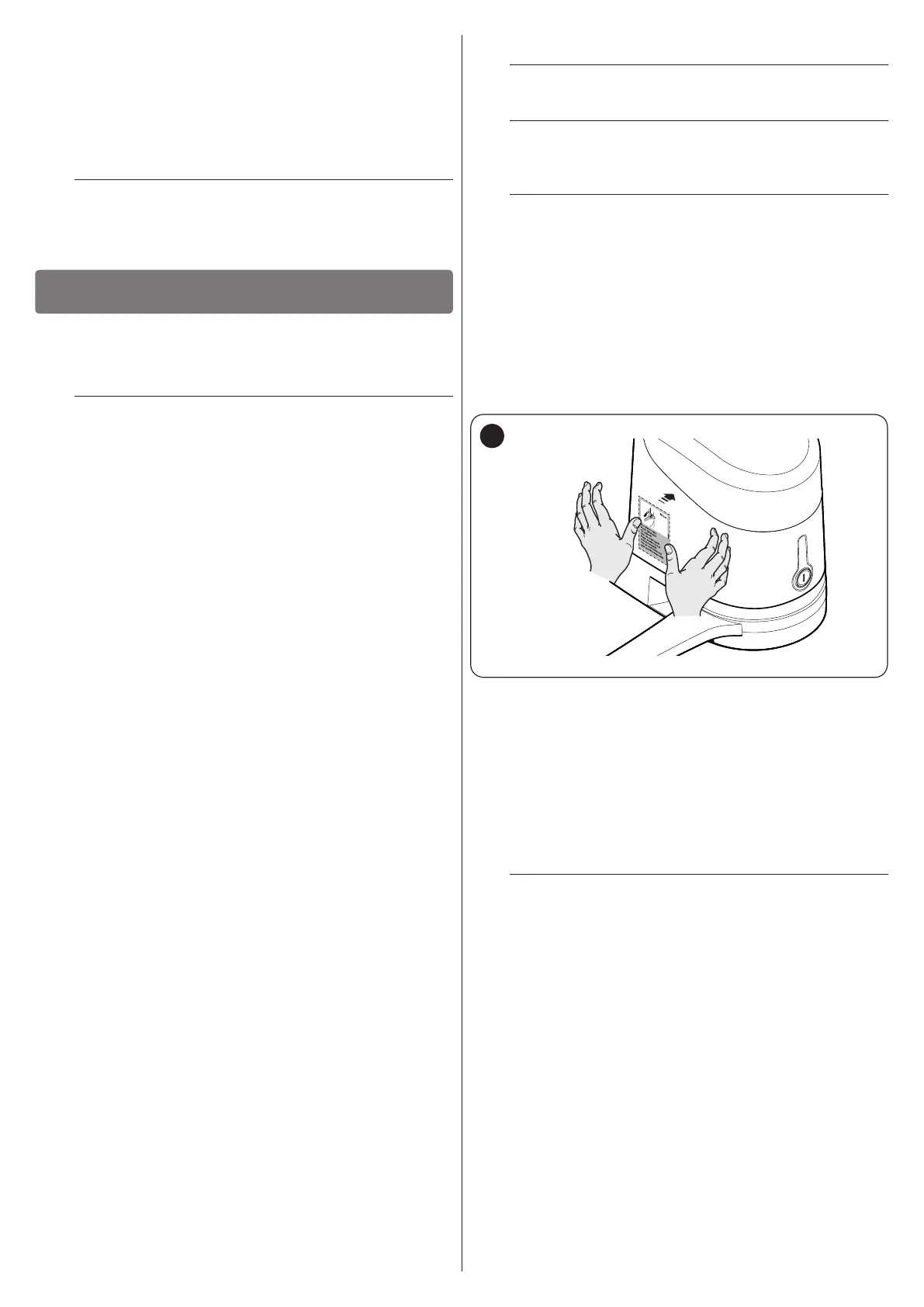

2. afx a permanent label or sign near the gate specifying

the operations for unlocking the gate and manoeuvring it

manually “Figure 49“

90°

49

3. afx a data plate on the gate specifying at least the

following data: type of automation, name and address of

the manufacturer (responsible for commissioning), serial

number, year of manufacture and CE mark

4. compile the declaration of conformity of the automation

and hand it to the owner of the automation

5. compile the User Manual of the automation and hand it to

the owner of the automation

6. compile and provide the owner with the automation’s

“Maintenance schedule”, containing the maintenance

instructions for all the automation’s devices.

l

For all the above-mentioned documentation, Nice –

through its technical assistance service – provides

the following: pre-completed forms.

Loading...

Loading...