ENGLISH – 7

Before starting the installation, it is necessary to determine

the length of the gearmotor arm – refer to the paragraph “

Determining the length of the gearmotor arm”.

3.5.1 Determining the length of the gearmotor arm

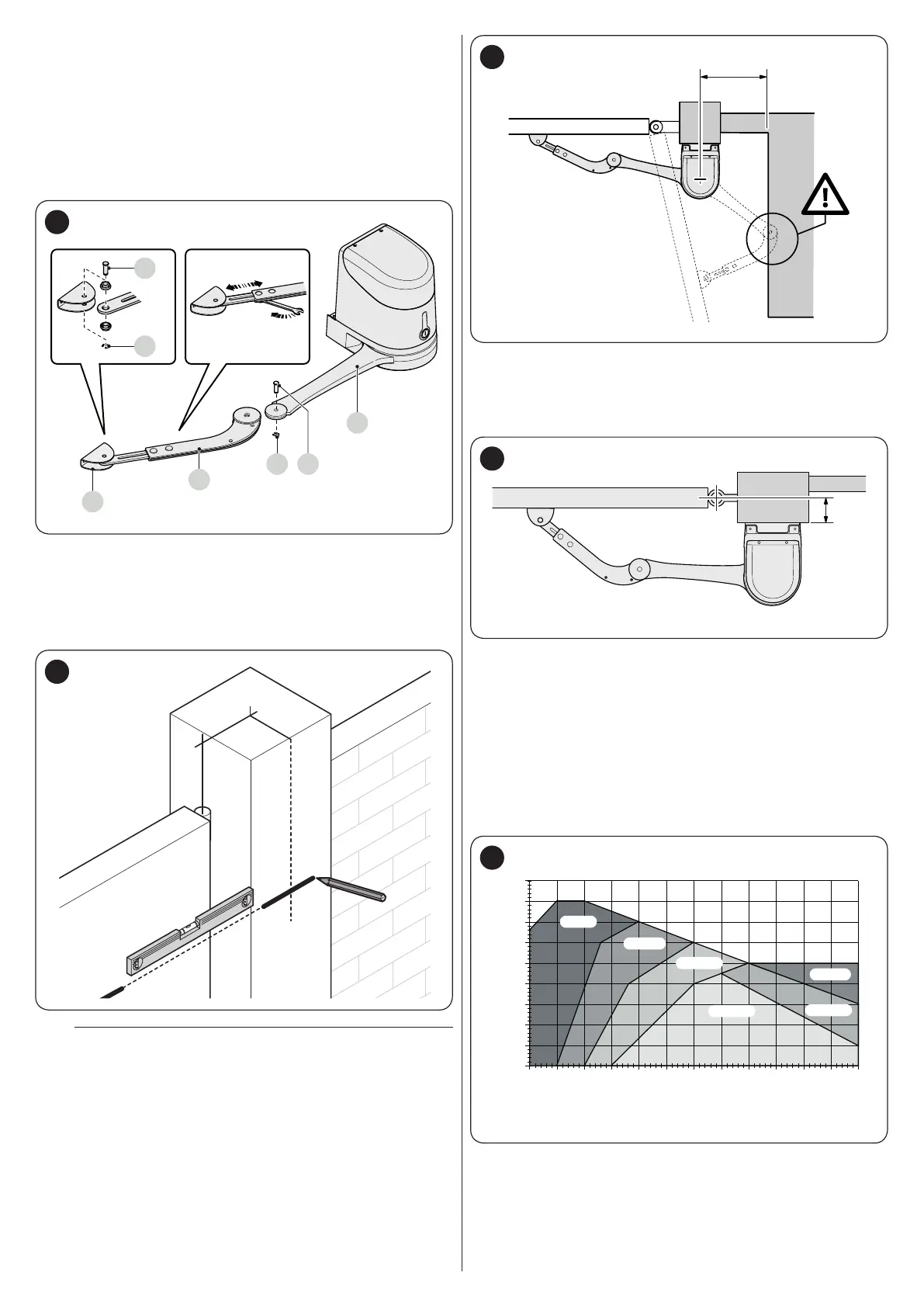

Assemble the components making up the motor arm::

1. attach the curved arm (A) to the straight arm (B) using the

pin (C) and retaining ring (D). likewise, attach the xing

bracket for the gate leaf (E) to the curved arm (A)

B

D

C

A

C

D

7

2. to dene the position of the gearmotor VERTICALLY,

draw a horizontal line on the pillar at the same height at

which the arm’s xing bracket will be on the leaf, after the

installation

3. dene the position of the gearmotor HORIZONTALLY

[level A].

A

8

a

If there is a xed obstacle (wall, tree, etc.) near the

installation area, measure distance E then proceed

as follows:

– If distance (E) is equal to or above 650 mm, consult

the paragraph “Installing the gearmotor with FULL-

LENGTH ARM”

– If distance (E) is between 300 mm (minimum) and 650

mm (maximum), consult the paragraph “Installing the

gearmotor with REDUCED-LENGTH ARM”.

9

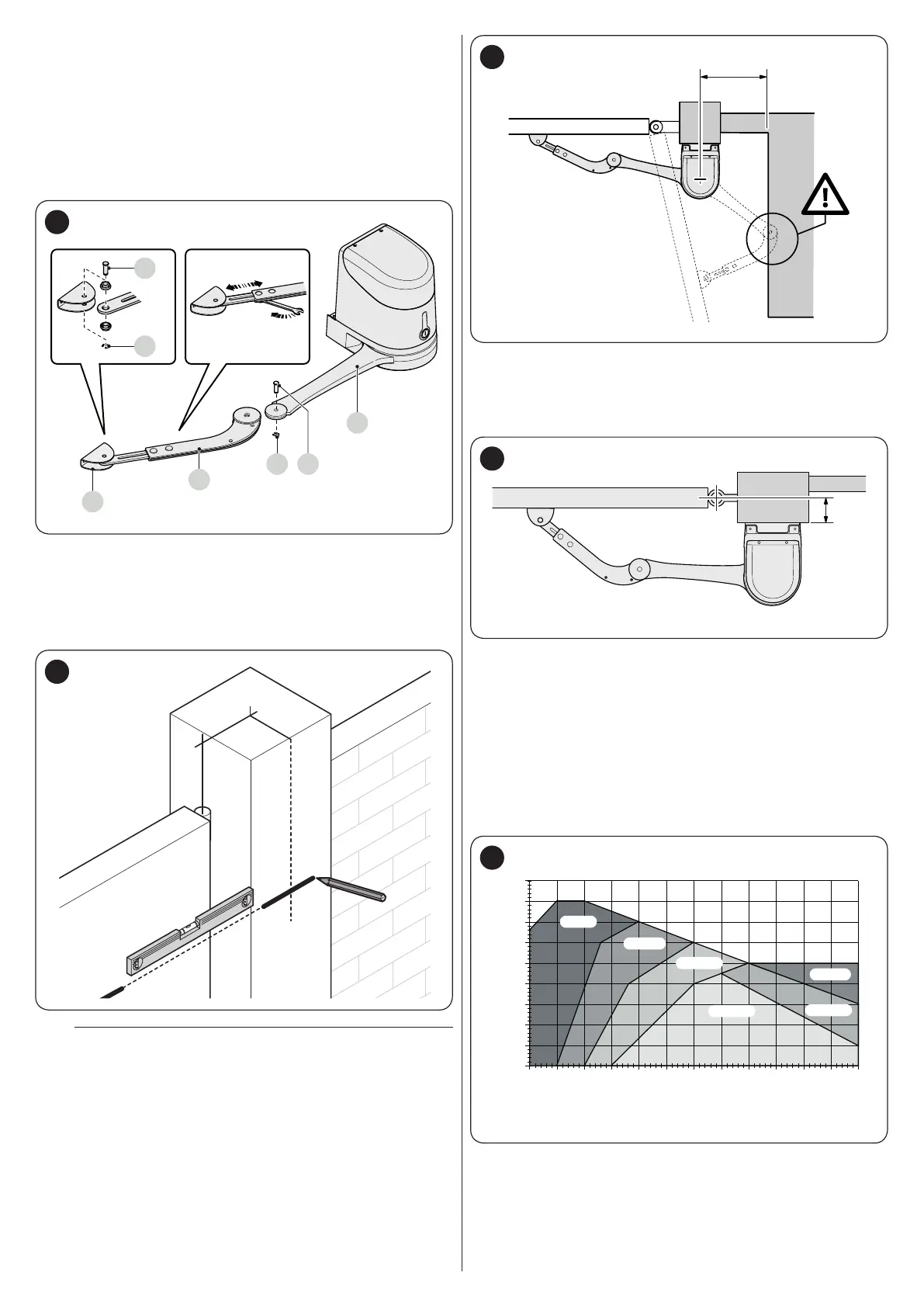

3.5.2 Installing the gearmotor with FULL-LENGTH ARM

To install HYKE:

1. measure the distance (B)

B

10

2. move the leaf to the desired maximum opening position

(maximum 110°) and check the resulting opening angle

3. mark the resulting distance (B) on the graph and, from

this point, draw a horizontal line intersecting the area that

includes the value of the measured opening angle

4. in the points of intersection between the horizontal line

and the area, draw a few vertical lines to determine the

values that can be used for level (A); choose in this range

a value for level (A). For example: if (B) is 200 mm and the

desired angle is 110°, level (A) will be between 300 mm

and 345 mm

0

150 175 200 225 250 275 300 325 350 400375 425

50

100

150

200

250

300

350

400

90°-95°

95°-100°

100°-105°

105°-110°

95°-105°

90°-95°

11

Loading...

Loading...