14 - FORM NO. 56043098 - Convertamatic

™

24, 26, 28, 32 / BA 625, 725, 825

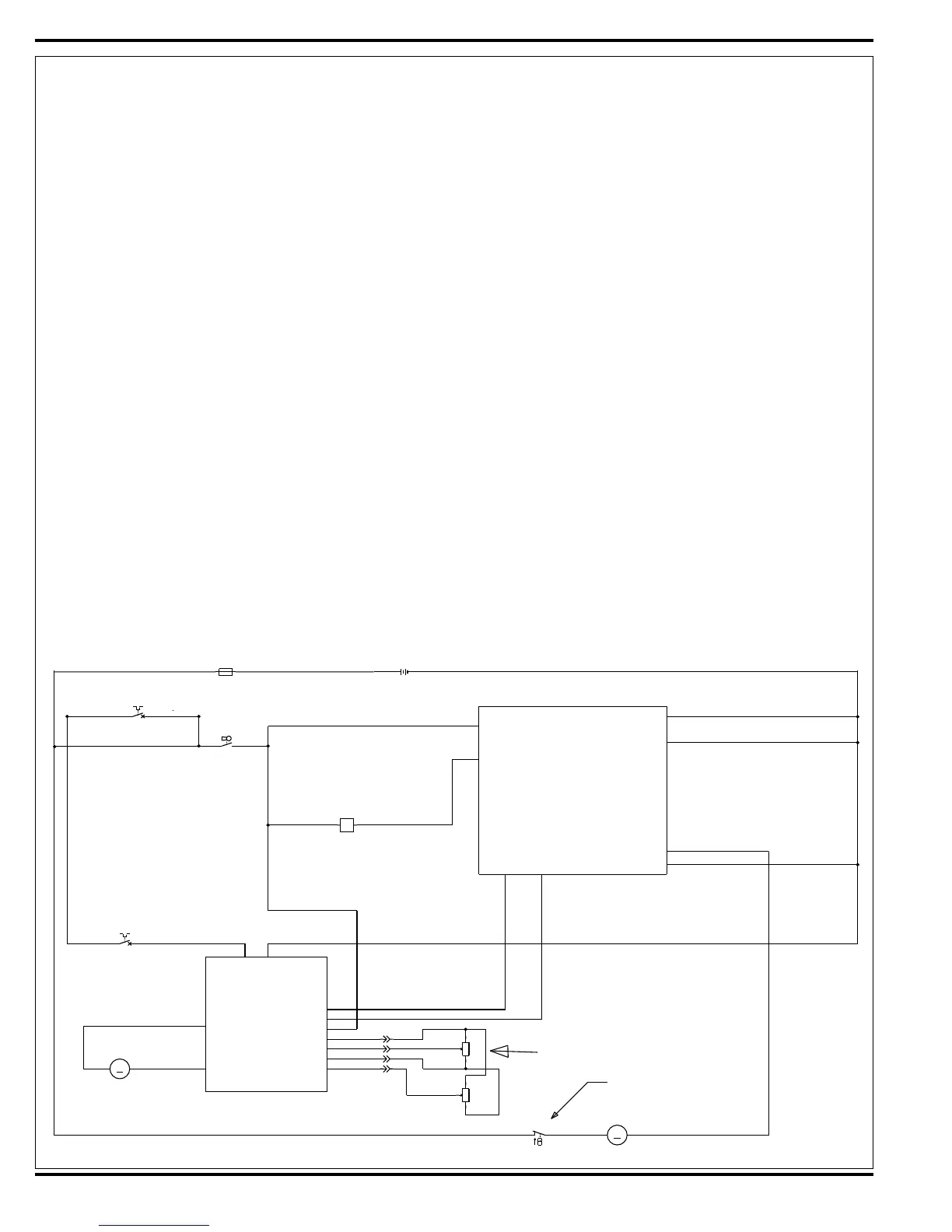

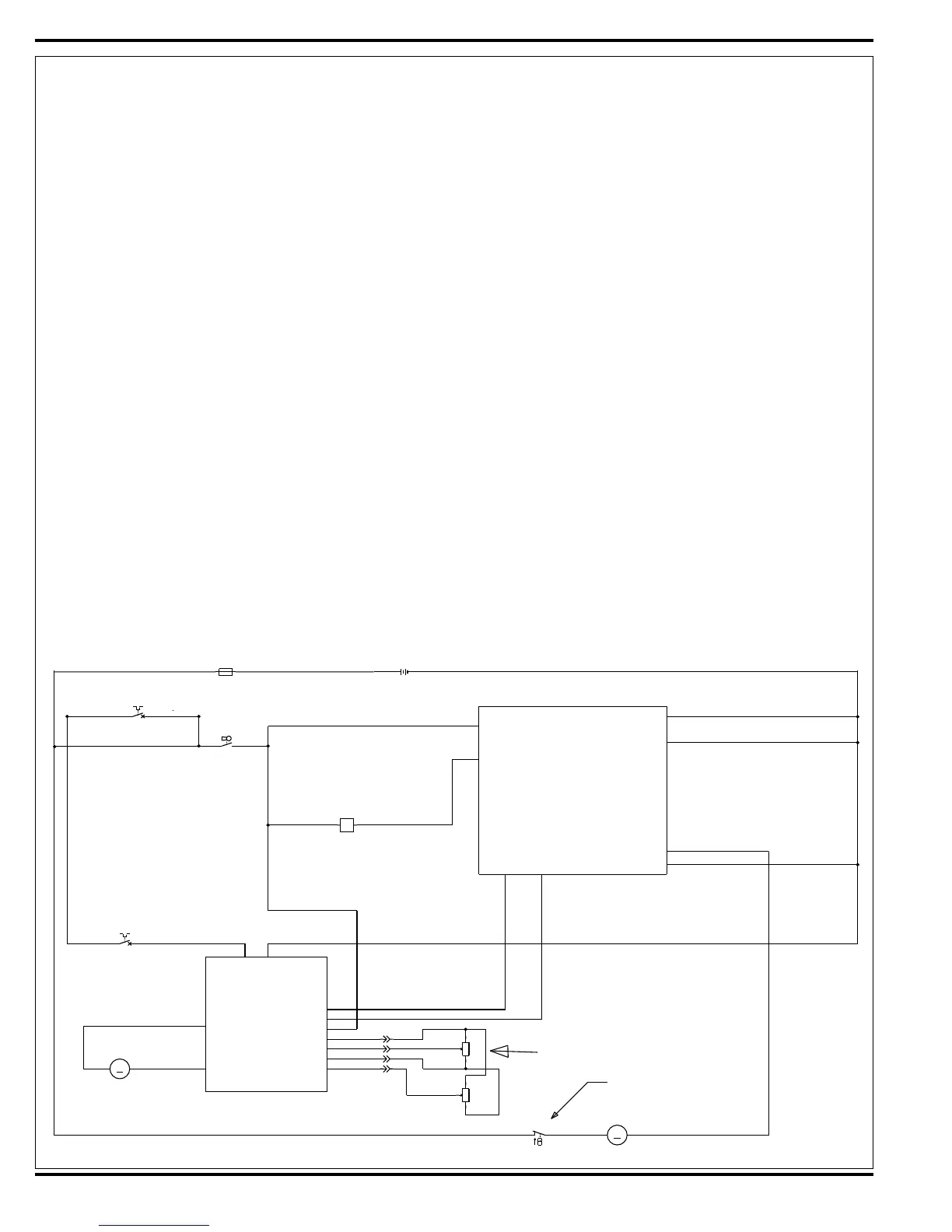

SOLUTION SYSTEM

CIRCUIT OVERVIEW SOLUTION AUTO MODE (SOLENOID VALVE CIRCUIT)

See Figure 2.

+ (Positive) circuit input starts with:

• A closed S3 key switch will direct the needed positive voltage (BRN wires) to the L1 solenoid coil and A1 control board terminal #J1-13.

- (Negative) circuit input starts with:

• A battery negative ground input at the A1 control board terminal #B2 (J1-9)

• The A1 control board solution button enabled.

• A negative voltage output from the A2 speed controller’s (pin #6) Red/Blk wire to the A1 control board Red/Blk wire (terminal J1-5). Note: The A2 speed controls

brake output (pin #6) occurs whenever the R1 direction throttle pot is moved off its neutral setting.

• A negative voltage output from the A1 board’s terminal J1-11 Red/Grn wire is direct to the L1 solenoid coil turning it on to allow fl ow through the valve body.

CIRCUIT OVERVIEW SOLUTION AUTO MODE (SOLUTION PUMP CIRCUIT)

See Figure 2.

+ (Positive) circuit input starts with:

• With the batteries connected the needed positive voltage (Red wires) to the M7 Solution Pump.

- (Negative) circuit input starts with:

• A battery negative ground input at the A1 control board terminal #B4 (J2-6)

• The A1 control board solution button enabled.

• A negative voltage output from the A2 speed controller’s (pin #6) Red/Blk wire to the A1 control board Red/Blk wire (terminal J1-5). Note: The A2 speed controls

brake output (pin #6) occurs whenever the R1 direction throttle pot is moved off its neutral setting.

• A negative voltage output from the A1 board’s terminal J1-8 Grn/Blk wire is direct to the M7 Solution Pump turning it on to allow fl ow to the L1 Water Valve

Solenoid. NOTE: The solution pump’s output volume is controlled by the A1 board’s programmable capability and changes the pulsing of the negative battery

connection to the pump.

Electrical Diagram

*For complete description of all callouts see Electrical System Wiring Diagram.

FIGURE 2

S1

M7

SOLUTIONPUMP

M

12

-+

GRN/BLK

RED

NOTE:SWITCHISPARTOF

PUMPASSEMBLY

R1

POT.5KOHMTHROTTLE

R2

POT.100KOHMSPEEDLIMIT

S3

SW,SPSTKEY

M1

MOTOR,WHEELDRIVE

M

F3

CIRCUITBREAKER,30AMP

F2

CIRCUITBREAKER,5AMP

L1

COIL,SOLUTIONSOLENOID

1

2

3

1

2

3

12

12

12

WHT

BRN/BLK

YEL/RED

RED

GRN

BRN

BLU

BLK

RED/BLK

BRN

RED/BLK

WHT/YEL

BRN

RED/GRN

RED

BLU/BLK

BLK

GRN/BLK

BLK

BLK

BLK

BLU/BLK

BRN

WHT

BLU

BLK

BRN

WHT

BLK

+-

B+1

SOLUTION

FOR/REV.

J1-13

J1-11

REVERSE

B-1

SOL.PUMP

B-4

B-2

A1

CONTROLBOARD

J1-5

J1-6

J1-7

J1-8

J2-6

J1-9

A2

B+ B-

1210SPEEDCONTROLLER

M1

M2

PIN3-POT.HI

PIN4-POT.WIPER

PIN13-POT.LO

PIN5-KSI

PIN16-REV

PIN6-BRAKE(-)

(1228FOR36V)

PIN9-STATUS

PIN18-SPEEDLIMITPOT

F1

FUSE,150A.

BT1

BATTERY

12

+-

RED

RED

BLK

24VDCOR36VDC

Loading...

Loading...