5-160

5-12 Simple Position Control Function

SYSDRIVE MX2 Series USER'S MANUAL (3G3MX2-A@@@@)

5

Functions

Simple Position Control Mode

When Pulse Train Input Terminal RP Selection (P003) is set to "01: Feedback pulse," the pulse

train signals are used as feedback information from the encoder. (Enabled for Control 1 only)

The position reference is specified by the combination of multi-function input terminals. Up to

eight position references can be specified.

The speed for a position command conforms to the Output Frequency Setting (F001). For data

with many digits, such as position commands, only the higher four digits are displayed. A run

command (FW or RV) is required separately as well as the position command. (Set A002 to

01.) This is needed to enable DC injection braking when stopping. During Digital Operator

operation (A002 = 2), DC injection braking does not function. DC injection braking functions

when A002 is 03 and A002 is 04.) For information on DC injection braking (DB), refer to

"Brake

Settings" on page 5-135

. (DC Injection Braking Power (A054) must be set. Set A051 to 00. Even

with these settings, DC injection braking will function for simple position control when external

DC injection braking is selected. For position control, external DC injection braking takes

priority, so do not set A051 to 01 or 02.)

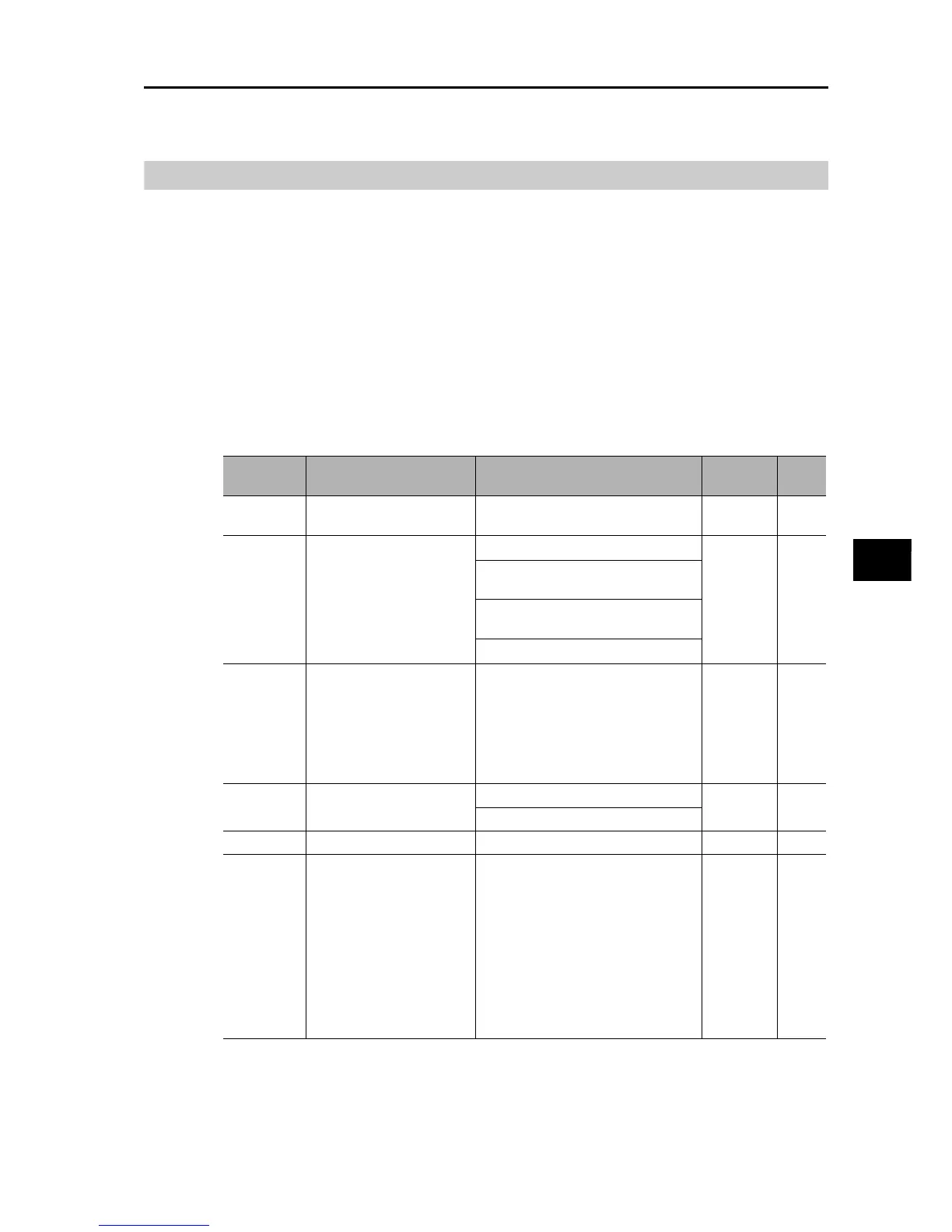

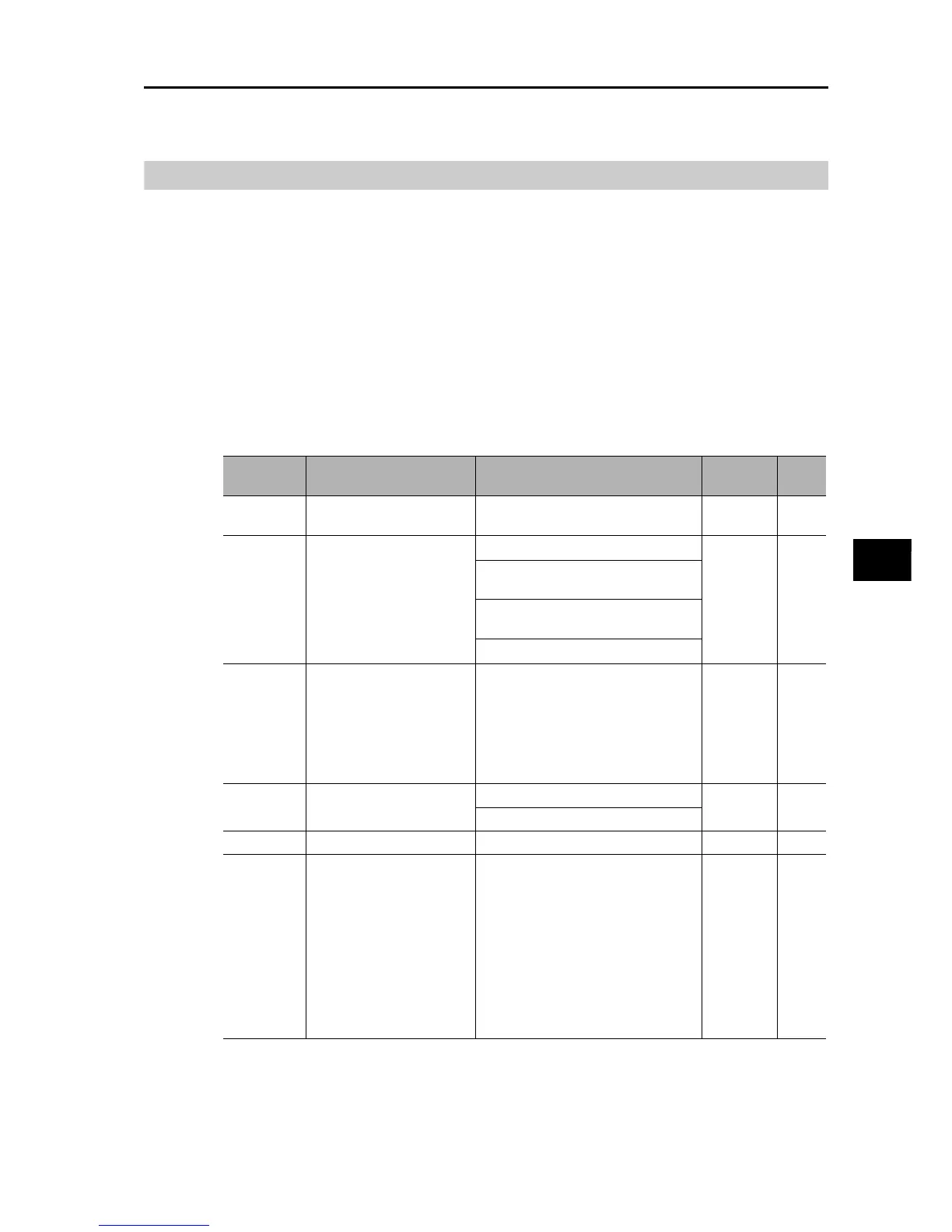

Parameter

No.

Function name Data

Default

setting

Unit

P003

Pulse Train Input Terminal

RP Selection

01: Feedback pulse

00 −

P004

Feedback Pulse Train Input

Type Selection

00: 1-phase pulse train

*2

00 −

01: Dual-phase pulse train with 90

°

phase difference 1

*1 , *2

02: Dual-phase pulse train with 90

°

phase difference 2

*1, *2

03: 1-phase pulse train + direction

*1, *2

P011 Number of Encoder Pulses

32. to 1024.

Set the calculated number of pulses

per motor rotation for each

connected encoder phase. This

setting is used for speed detection

and position control by calculating

pulse to stop.

512.

Pulse

P012

Simple Position Control

Selection

00: Simple position control disabled

00 −

02: Simple position control enabled

P015 Creep Speed Setting Starting frequency to 10.00 (100.0) 5.00 Hz

P026

Overspeed Error Detection

Level

0.0 to 150.0

The Inverter will be tripped if the

motor speed detected by the encoder

exceeds the maximum frequency

times the Overspeed Error Detection

Level (P026) during operation when

P003 is set to 01 (encoder feedback)

and P026 is not set to 0.

This does not depend on whether

simple position control of V/f control

with FB is ON or OFF.

115.0 %

Loading...

Loading...