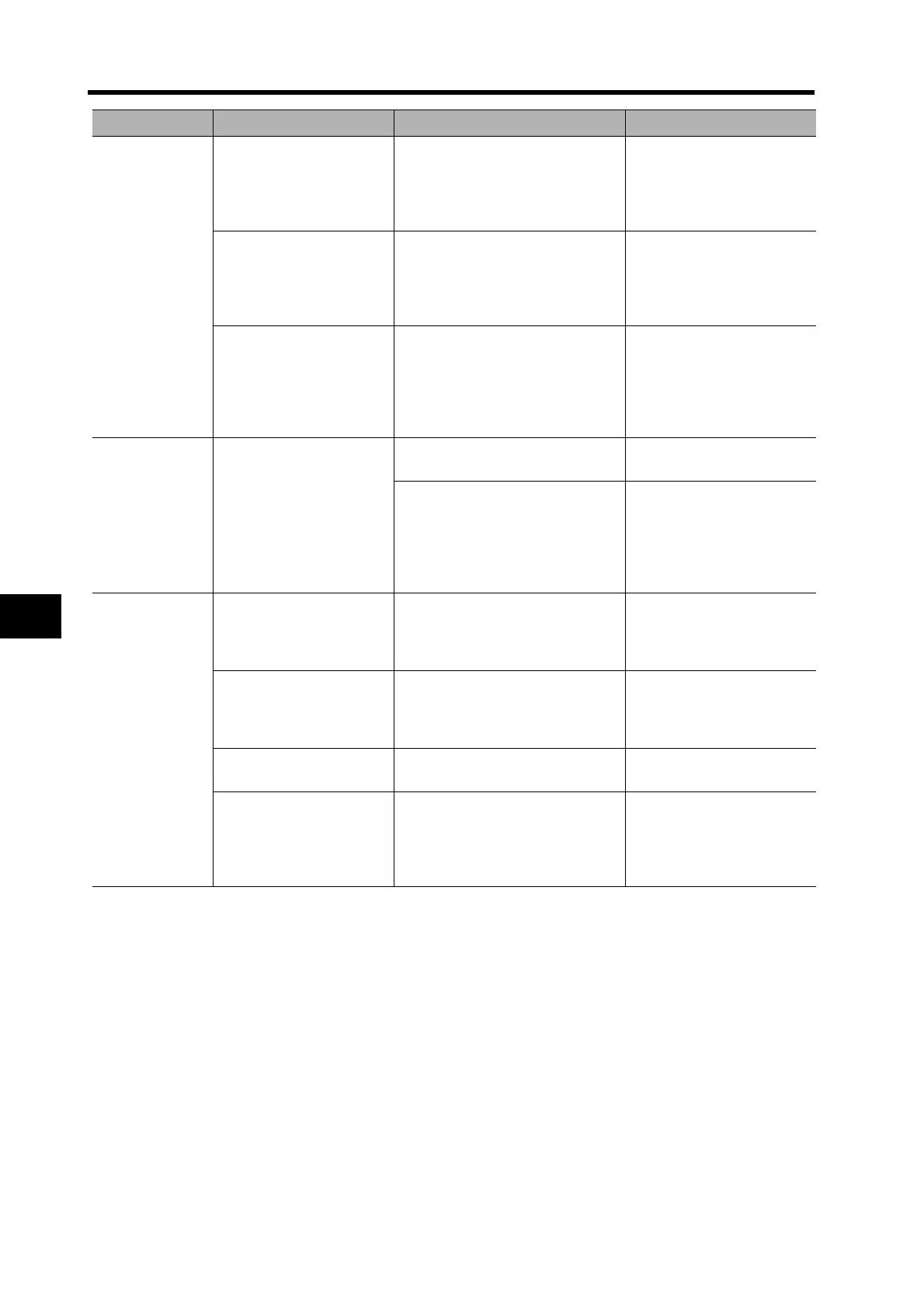

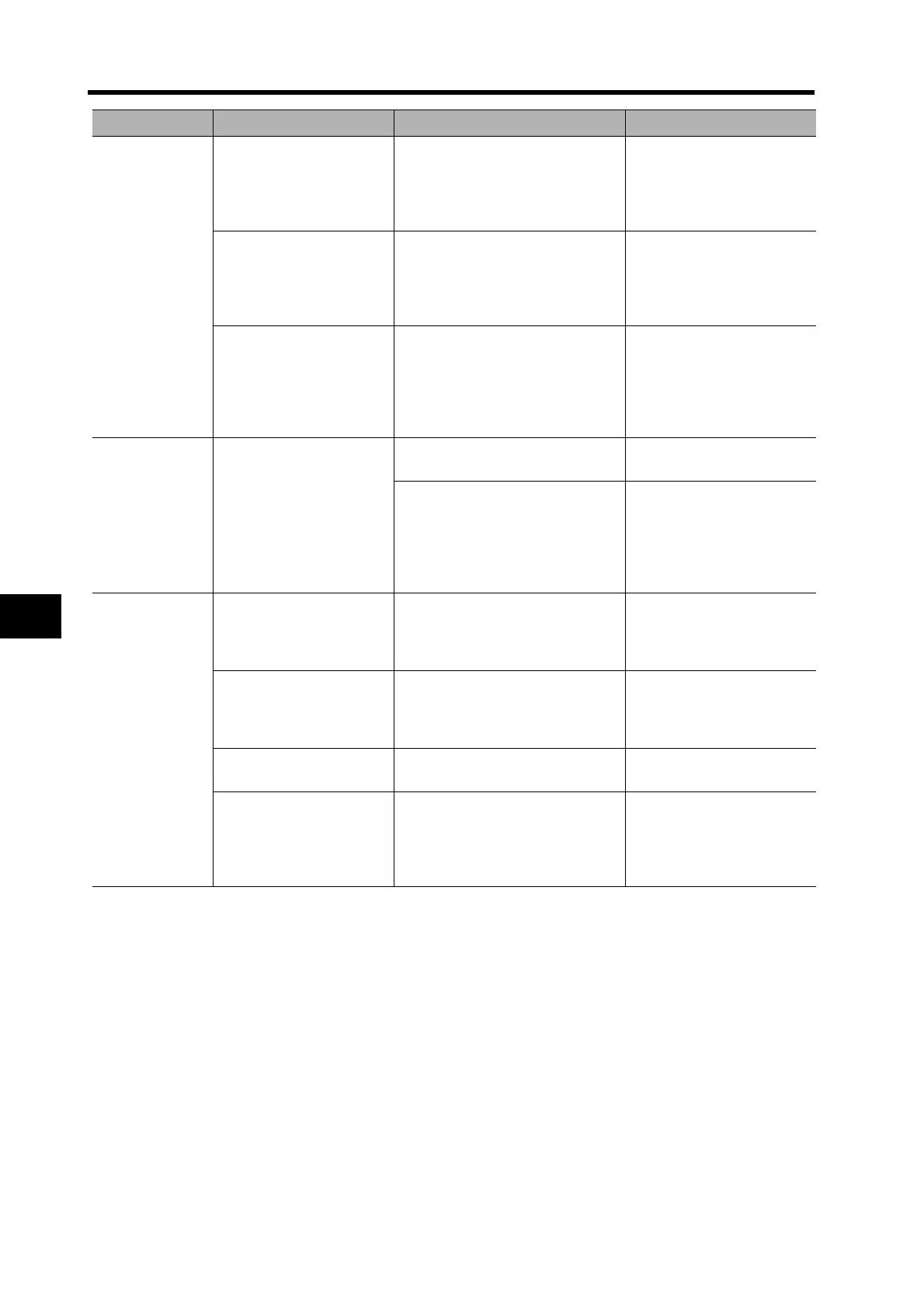

8-15

8-3 Troubleshooting

8

Troubleshooting

The Servomotor

is producing

unusual noises

or the machine is

vibrating.

(Continued from

previous page.)

The FG’s potential is fluc-

tuating due to devices near

the Servomotor, such as a

welding machine.

Check for grounding problems (fail-

ure to ground or incomplete

grounding) at devices such as a

welding machine near the Servo-

motor.

Ground the equipment prop-

erly and prevent currents

from flowing to the encoder

FG.

Errors are being caused by

excessive vibration or

shock on the encoder.

There are problems with mechani-

cal vibration or motor installation

(such as the mounting surface pre-

cision, attachment, or axial mis-

alignment).

Reduce the mechanical vi-

bration or correct the Servo-

motor’s installation.

The machine and the Ser-

vomotor are resonating.

Check whether the machine is res-

onating.

• Readjust the Torque Com-

mand Filter Time Constant.

• If there is resonance, set

the Notch Filter 1 Frequen-

cy (Pn1D) and Notch Filter

1 Width (Pn1E).

Vibration is

occurring at the

same frequency

as the power

supply.

Inductive noise is occur-

ring.

Check whether the Servo Drive

control signal lines are too long.

Shorten the control signal

lines.

Check whether control signal lines

and power supply lines are bundled

together.

• Separate control signal

lines from power supply

lines.

• Use a low-impedance

power supply for control

signals.

The position is

misaligned.

(Position mis-

alignment occurs

without an alarm

being output.)

There is an error in the

coupling of the mechanical

system and the Servomo-

tor.

Check whether the coupling of the

mechanical system and the Servo-

motor is misaligned.

Couple the mechanical sys-

tem and the Servomotor cor-

rectly.

Noise is entering the Devi-

ation Counter Reset Input

(ECRST).

Check whether the control signal

lines and power supply lines are

bundled together.

Take measures against

noise, such as separating

the control signal lines and

power lines.

The gain is does not

match.

--- • Use autotuning.

• Perform manual tuning.

The load inertia is too

large.

Check the following:

• Check whether the load is too

large.

• Check whether the rotation speed

of the Servomotor is too high.

• Adjust the gain.

• Review the load condi-

tions, and replace the Ser-

vomotor and Servo Drive

with appropriate models.

Symptom Probable cause Items to check Countermeasures

Loading...

Loading...