Maintenance

OPTIMUM

MASCHINEN - GERMANY

© 2008

GB

Page 36 Metal belt saw S210G; S275G; S210G Vario; S275G Vario version 1.3.1 4 February 2008

If there have been

curved cuts, brea-

kage of teeth, war-

ping or breakage of

the guide rollers.

Saw arch

Adjusting the pres-

sure of the saw

arch

Place the saw arch in the upper position and close

the shut-off tap on the hydraulic cylinder.

Place a level in the work-holder vice.

Let the saw arch descend slowly.

Fully open the shut-off tap on the hydraulic cylinder

once the saw belt has made contact with the level.

The support force of the saw arch on the level should

come to 15 - 16 kg.

If necessary, correct the value by changing the posi-

tion of the spring using the setscrew.

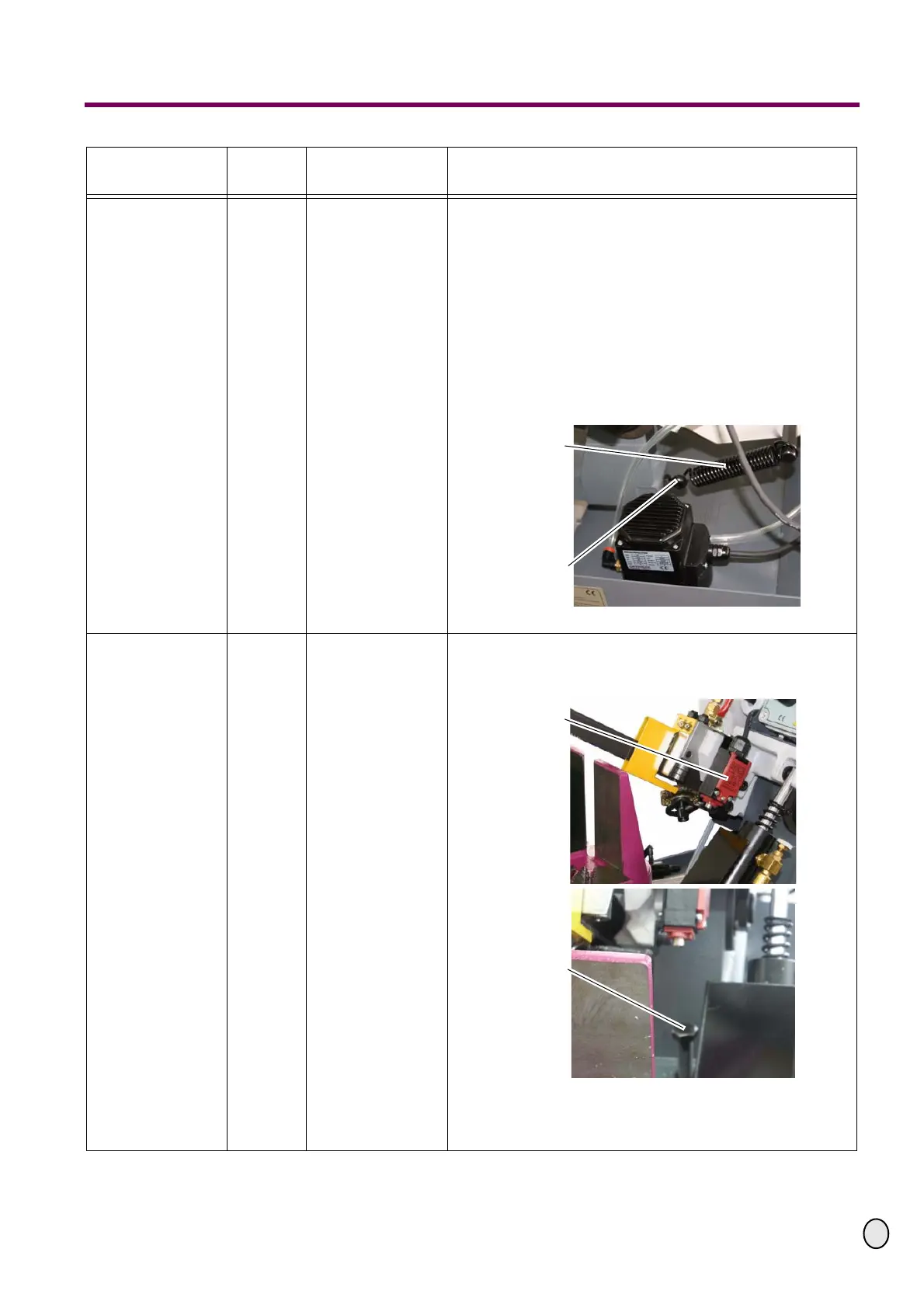

Illustr.6-2: Pressure of the saw arch

If the metal belt

saw and the coo-

ling pump continue

to operate after the

sawing process is

complete.

If the metal belt

saw and the coo-

ling pump discon-

nect before the

sawing process is

complete.

Adjusting the end

stop switch

Turn the screw on the end stop switch up or down so

that it comes into contact with the end stop switch

when the sawing process finishes.

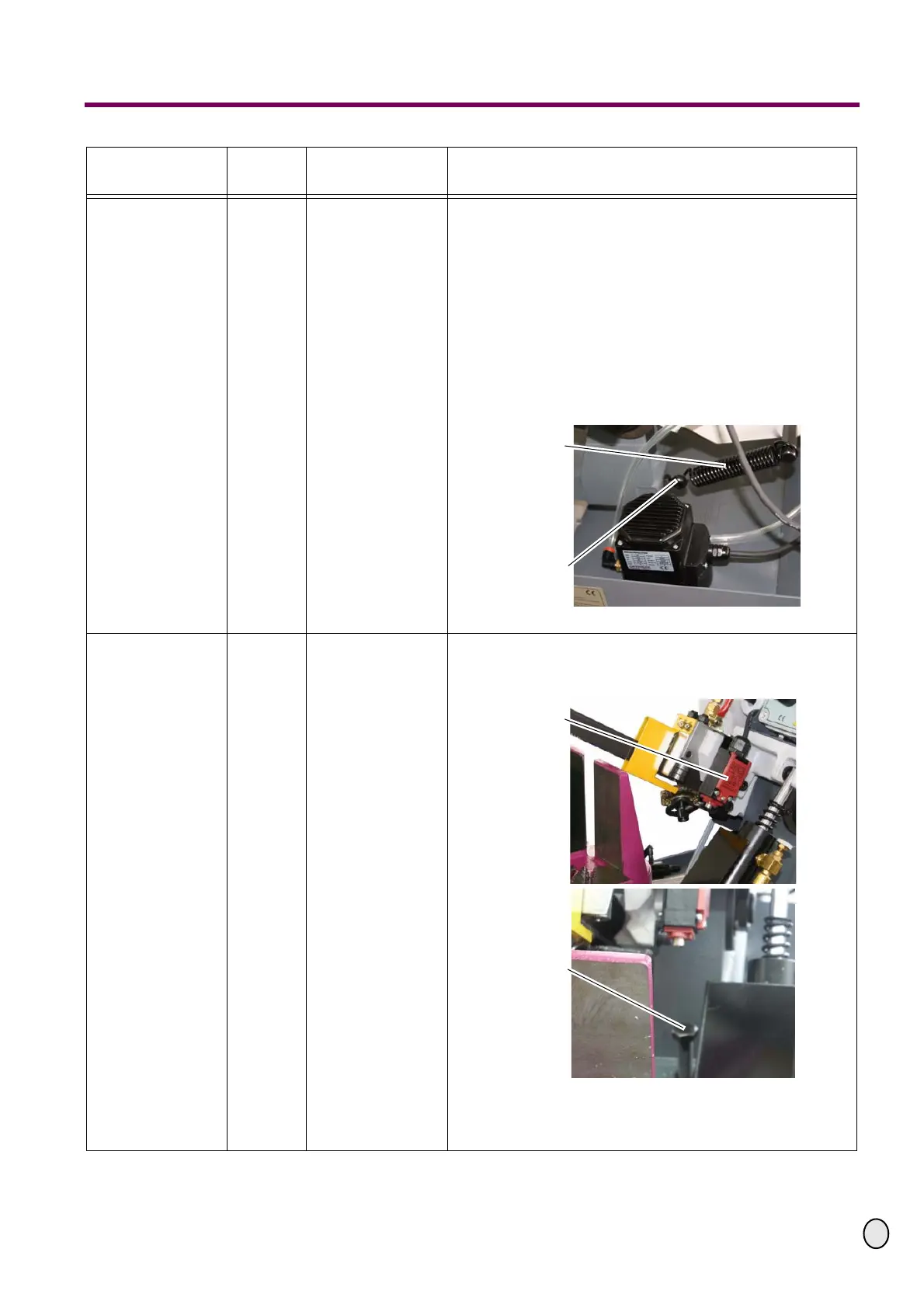

Illustr.6-3: End stop switch

Check the end stop of the saw arch. It should coin-

cide with disconnection of the end stop switch.

Intervals /

When?

Where? What? How?

Spring

Setscrew

End stop switch

Adjustable end stop

disconnection

Loading...

Loading...