MX-5050 Operation and Maintenance Manual

May 1992

Section 6 Transport Adjustment and Parts Replacement

6 - 11

6.9 Head Position Adjustment

Whenever replacing a head, the following head position adjustments are

necessary. If the tape does not contact the heads properly, perform the

following adjustments.

NOTE: If the tape does not contact the heads properly due to improper

alignment, any one of the following problems may occur.

Reproduce Head Wrong Position

High Frequency Level Decreasing

Level Fluctuation

Record Head Wrong Position

High Frequency Level Decreasing

Level Fluctuation

Erase Head Wrong Position

Deterioration of the Erase Ability

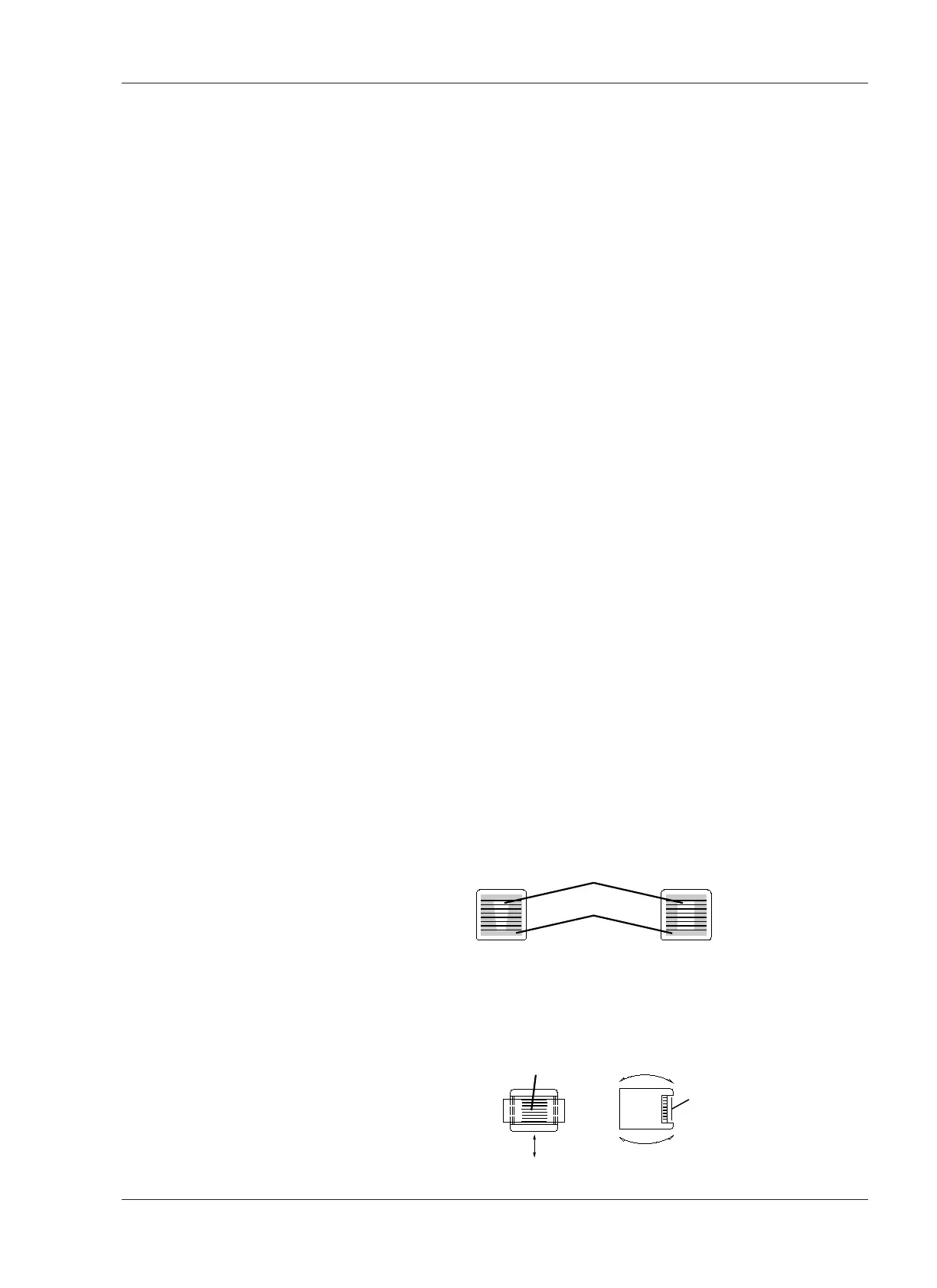

❏ Height /Zenith Adjustment

Perform the following adjustment after raising the head cover.

1. Thread the machine with a tape that can be disposed of after use.

2. Adjust the head height and zenith visually by turning the screws marked "T"

and "H" in Figure 6-9 to move the tape to the middle of the head.

3. After the adjustment, mark the head surface with Head Marker Ink or a

Marker Pen.

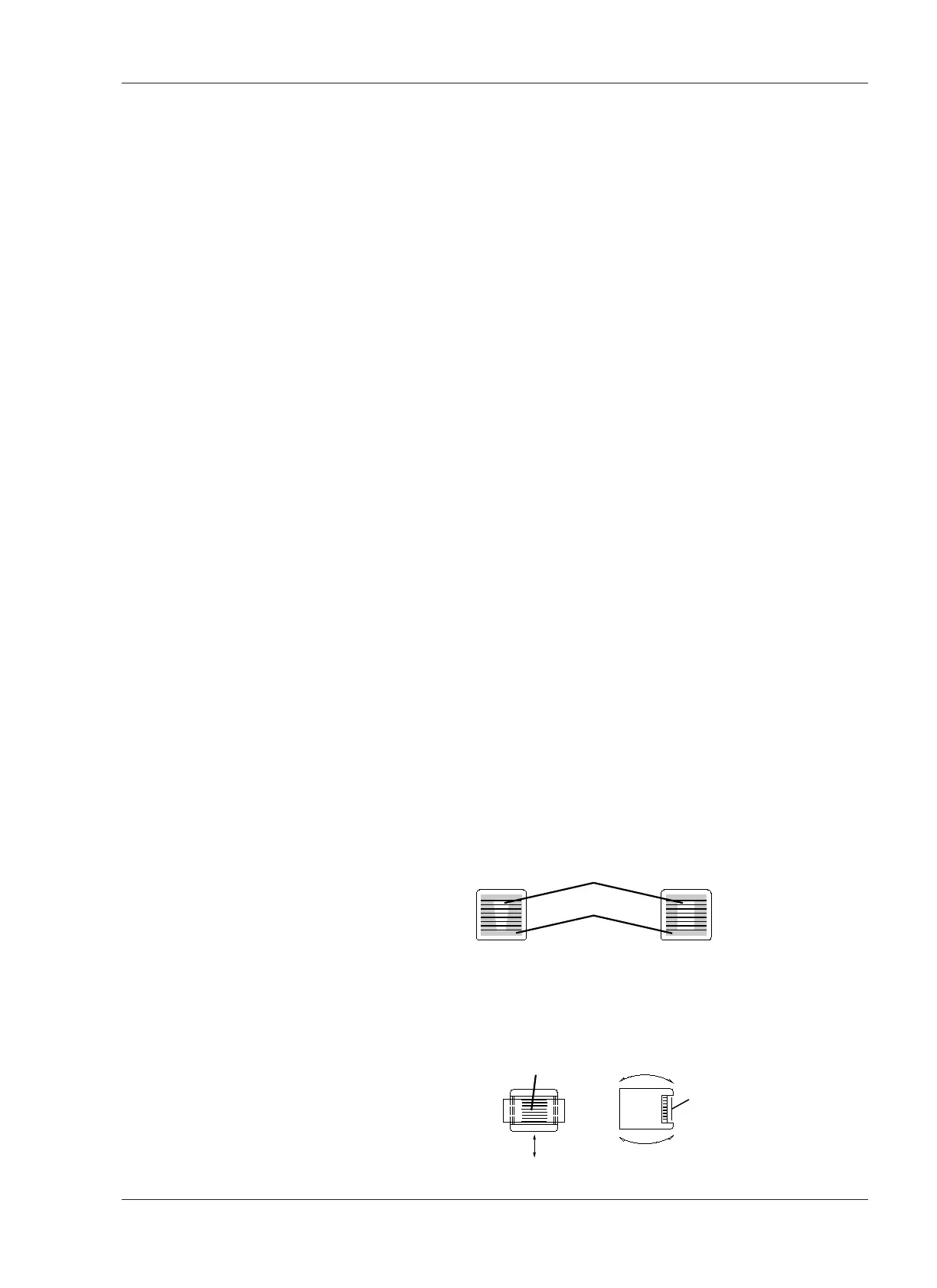

4. Play the tape for about ten seconds.

5. Inspect the face of each head where the passage of the tape has worn away

the ink. If the wear pattern does not match that shown in Figure 6-10,

readjust the screws " T" and " H ".

6. After reapplying the ink, play the tape as in step 4, and again inpsect the face

of each head. Repeat this process until the wear pattern is correct.

Loading...

Loading...