Parker Hannifin S.p.A. - S.B.C. Division HPD N User’s Manual

63

4.8.2. Examples and applications

The following examples illustrate possible functionalities obtained by suitable

programming of the HPD pico-PLC. The suggested solutions offer the possibility of reducing

the components required to build the machine or part of the machine while, in many cases,

also cutting the overall cost of the application. Note that the pico-PLC scanning time is 6.144

msec and the maximum number of instructions is 64; moreover, the PLC is designed

principally to manage the drive’s digital inputs and outputs.

In addition to a concise description of the application, the examples show the settings

required for HPD parameters and the pico-PLC program. The program is shown in ladder

diagrams and instruction listings.

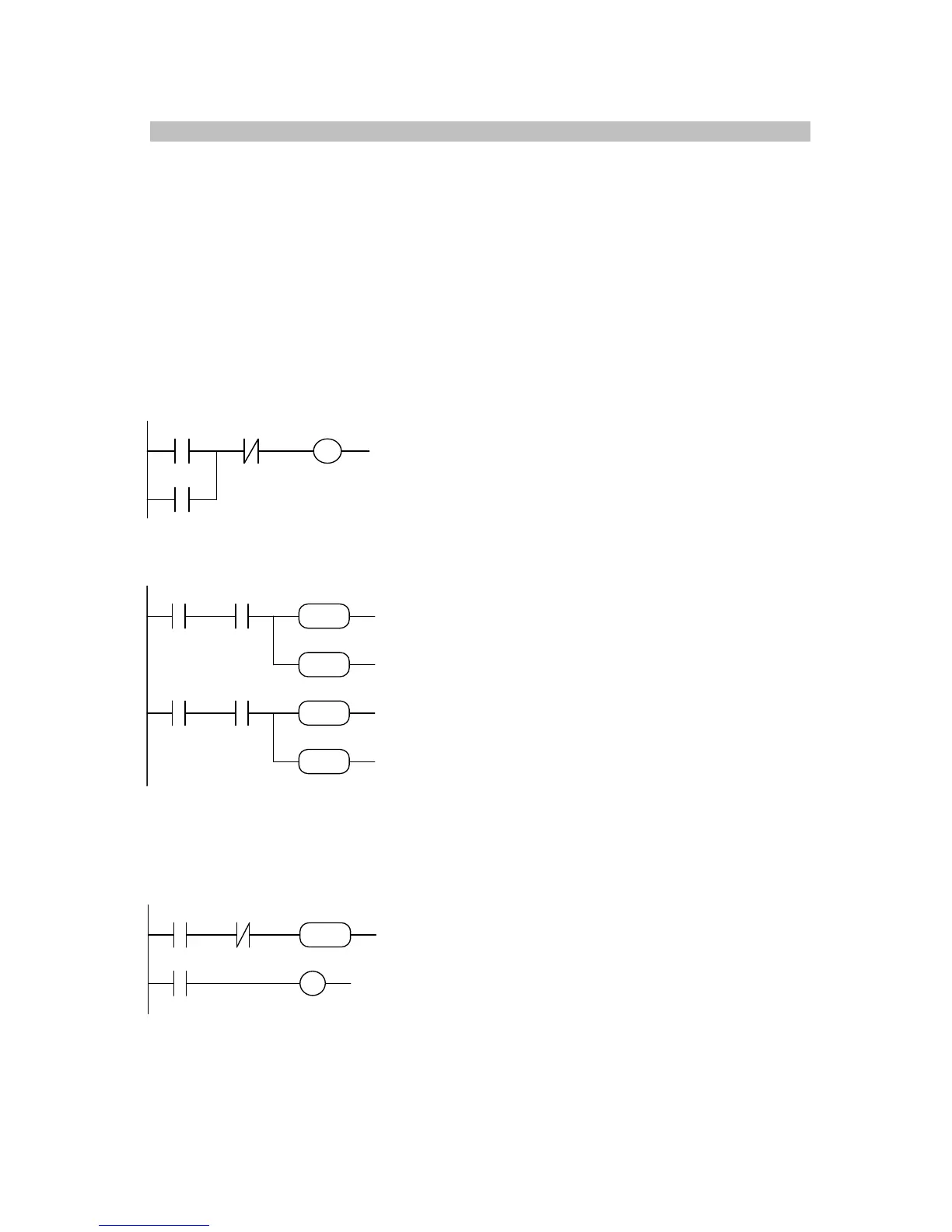

Example 1: two inputs for on/off functions

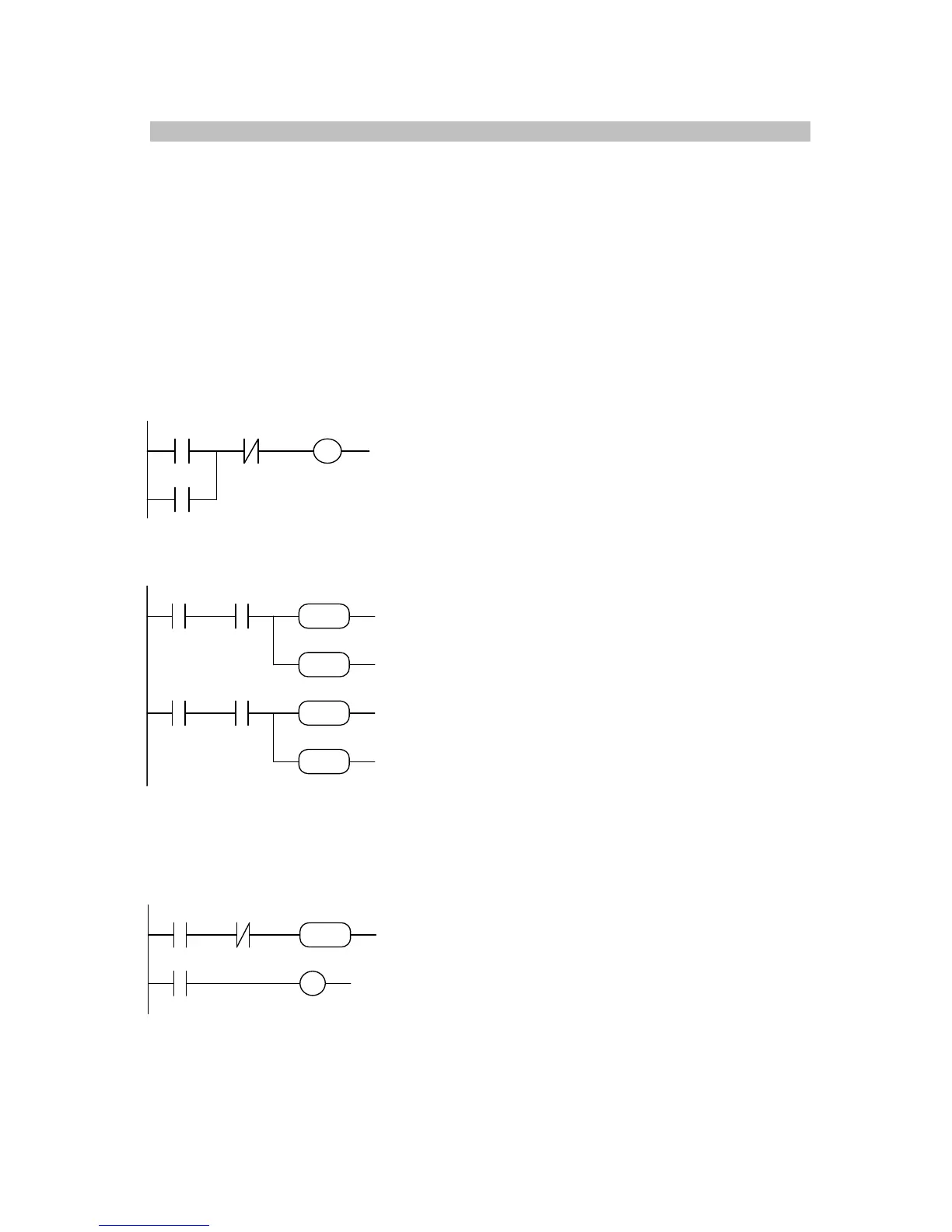

Example 2: changing a parameter value with the up/down keys

Example 3: command on positive front of a digital input

90.1 90.2 91.2

91.2

digital input 1 sets bit b91.2 to on

digital input 2 sets bit b91.2 to off

LD 90.1

OR 91.2

ANDN 90.2

OUT 91.2

LD 09.1

AND 99.0

ADD 05.73.05

ADD 92.76.92

LD 90.2

AND 99.0

ADD 05.71.05

DD 92.76.92

digital input 1 in high status increases

parameter Pr5 by one unit every 614

msec

digital input 2 in high status decreases

parameter Pr5 by one unit every 614

msec

ADD

ADD

92 76 92

05 73 0590.1 99.0

ADD

ADD

92 76 92

05 71 0590.2 99.0

LD 90.1

ANDN 90.10

SET 70.8

LD 90.1

OUT 90.10

digital input 1 sets bit b70.8 just once

when the signal changes from low to

hi

Loading...

Loading...