INTELLIPRO

®

Variable Speed Pump Installation and User’s Guide

22

INTELLIPRO

®

Variable Speed Pump Installation and User’s Guide

Drive Assembly Removal and Installation

To remove the drive assembly and control panel from

the pump’s motor assembly:

1. DisconnecttheRS-485communicationcablefrom

the pump.

2. Openthecontrolpanelcover.

3. RemovethethreePhillipsheadscrewssecuringthe

drive to the motor assembly as shown.

4. Liftupthedriveassemblyandremoveitfromthe

motor adapter located on top of the motor assembly.

To avoid electrical hazard, do not remove the four

tamper proof screws from the motor assembly.

To avoid dangerous or fatal electrical shock

hazard, switch OFF power to motor before working

on pump or motor.

Continue onto next page

Pump Reassembly/Installing New Seal

1. Cleantheceramicseatofdirt,grease,dust,etc.

Wet the outer edge of the rubber cup on the ceramic

seat with water. Press the ceramic seat into the seal

plate firmly and squarely with finger pressure. See

seal image below.

2. Placeceramicseatfaceuponbenchandreclean

thecavityifseatdoesnotlockproperly.

3. If the seat still does not lock properly, place a

cardboard washer over the polished face and use

apieceof3/4”(19mm)standardpipeforpressing

purposes.

4. Remountsealplateonthemotor.Tightenthebolts

to60-80inch-lbs.(69-92kg/cm)torque.

5. Apply a small amount of liquid detergent to the

inside diameter of rotating half of seal.

6. Slidetherotatingsealmember,polishedfacelast,

over impeller sleeve until the rubber drive ring

contacts the shoulder. Note: Besurenottonickor

scratchthepolishedsealface.Thesealwillleakif

the face is damaged.

7. Screwtheimpellerontotheshaft(clockwise);this

will automatically lock the seal in the seal plate.

Note: Onmodelswithanimpellerscrew:Installthe

impellergasketandlockscrew(left-handthread-

turncounter-clockwise).Torquelockscrewto50-55

inch-lbs.(57.6-63kg/cm).

8. Mountthediffuseronthesealplate.Tightenscrews

to10-14inch-lbs.(11.2-16.1kg/cm)torque.

9. Assemblethemotorandsealplatetothevolute.

Be sure the clamp is properly seated

Note: Clampknobcanbelocatedinanyposition

aroundvolute;ifitismovedafterassembly,tighten

knobwhiletappingaroundclamptoassistsealing.

Donotmoveclampwhilepumpisfullofwater.

10. ReconnecttheRS-485communicationcabletothe

pump.

11. Fillthepumpwithwater.

12. Reinstallthepumplidandplasticclamp.See“Pump

StrainerBasket”onpage20fordetails.

13. Primethepump.See“PrimingthePump,”onpage

4formoreinformation.

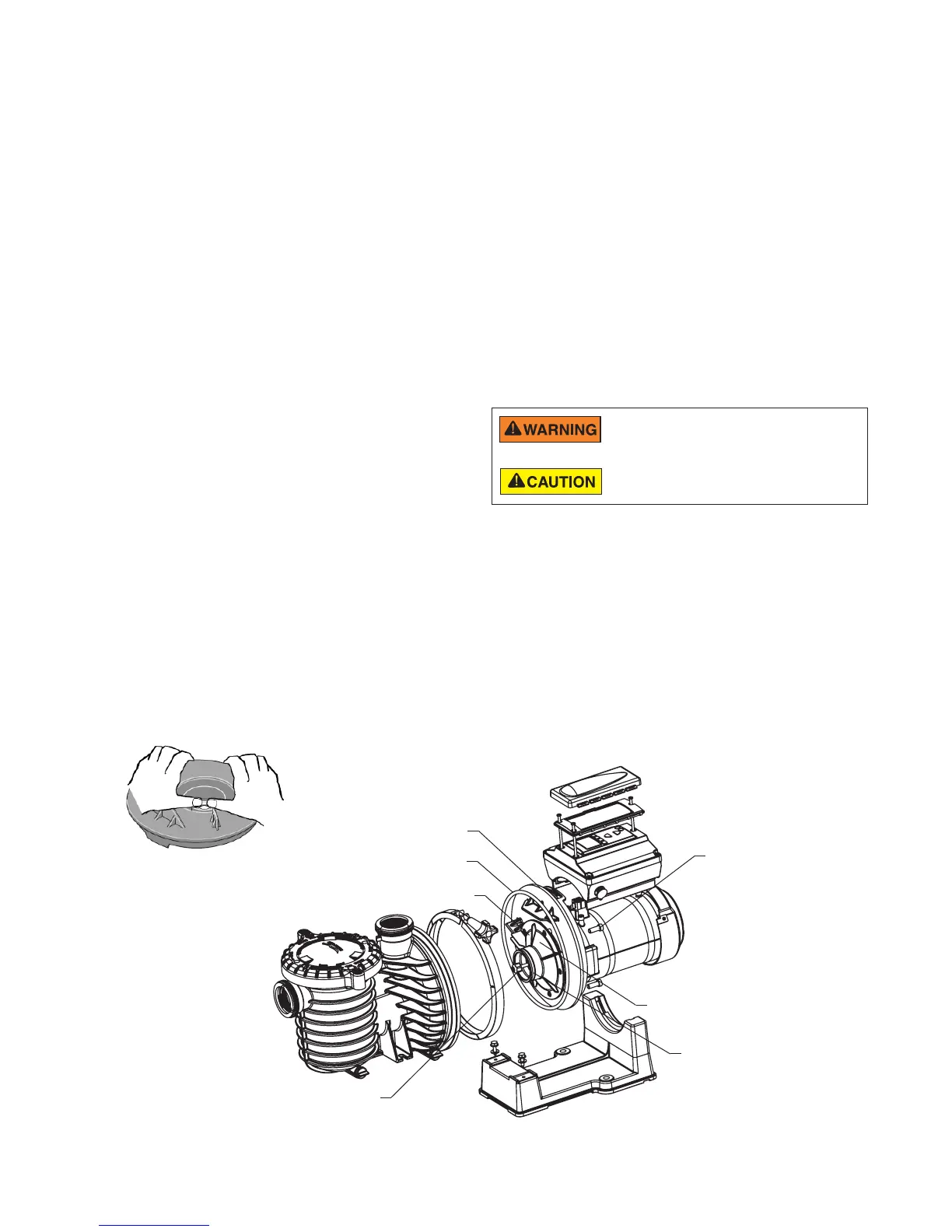

Illustrated Parts View

Seal Plate

O-Ring

Diffuser

Impeller Screw

MotorBolts(4x)

Impeller(notshown)

O-Ring

Press Seal into plate firmly

Loading...

Loading...