23

INTELLIPRO

®

Variable Speed Pump Installation and User’s GuideINTELLIPRO

®

Variable Speed Pump Installation and User’s Guide

Alerts and Warnings

The IntelliPro

®

Variable Speed Pump displays all alarms

and warnings on the control panel display. When an alarm

or warning condition exists, the corresponding light will

be lit on the display.

Allcontrolpanelbuttonsaredisableduntilthealarmor

warningisacknowledgedwiththeEnterbutton.Pressthe

Resetbuttontoclearthealarmoncethefaultcondition

has been resolved.

Note: The pump will not start if the impeller is rotating.

Power Out Failure

Theincomingsupplyvoltageislessthan170VAC.

The drive faults to protect itself from over current. The

drivecontainscapacitorsthatkeepitpowereduplong

enough to save the current run parameters. If power is

restoredduringthisprocess,approximately20

seconds, the drive will not restart until completed.

Priming Error

If the pump is not dened as primed within the“Max

Priming Time” it will stop and generate a “Priming

Alarm”for10minutes,thenattempttoprimeagain.The

“Max PrimingTime” is set by the user on the priming

menu as discussed on page 14. If the pump cannot

prime within five attempts it will generate a permanent

alarm that must be manually reset.

Overheat Alert

Ifthedrivetemperaturegetsabove54.4°C(130°F)

the pump will slowly reduce speed until the over

temperature condition clears.

Anti-Freezing

Whenactive,themotorwillrunatthepresetRPMuntil

the drive temperature increases above the minimum. The

pump’s internal antifreeze protection is disabled when

connectedtoanautomationsystem.Freezeprotection

isprovidedbyselectingYESattheONWITHFREEZE

portion of the circuit function menu in the IntelliTouch

®

Control System. To re-enable the internal antifreeze

protection, the power to the drive must be cycled off

then backon.Important: See explanation of Anti-

Freeze mode on page 16.

Over Current

Indicated that the drive is overloaded or the motor has

anelectricalproblem.Thedrivewillrestart20seconds

after the over current condition clears.

Over Voltage

Indicates excessive supply voltage or an external

water source is causing the pump and motor to rotate

thereby generating an excessive voltage on the drives

internalDCbuss.Thedrivewillrestart20seconds

after the over voltage condition clears.

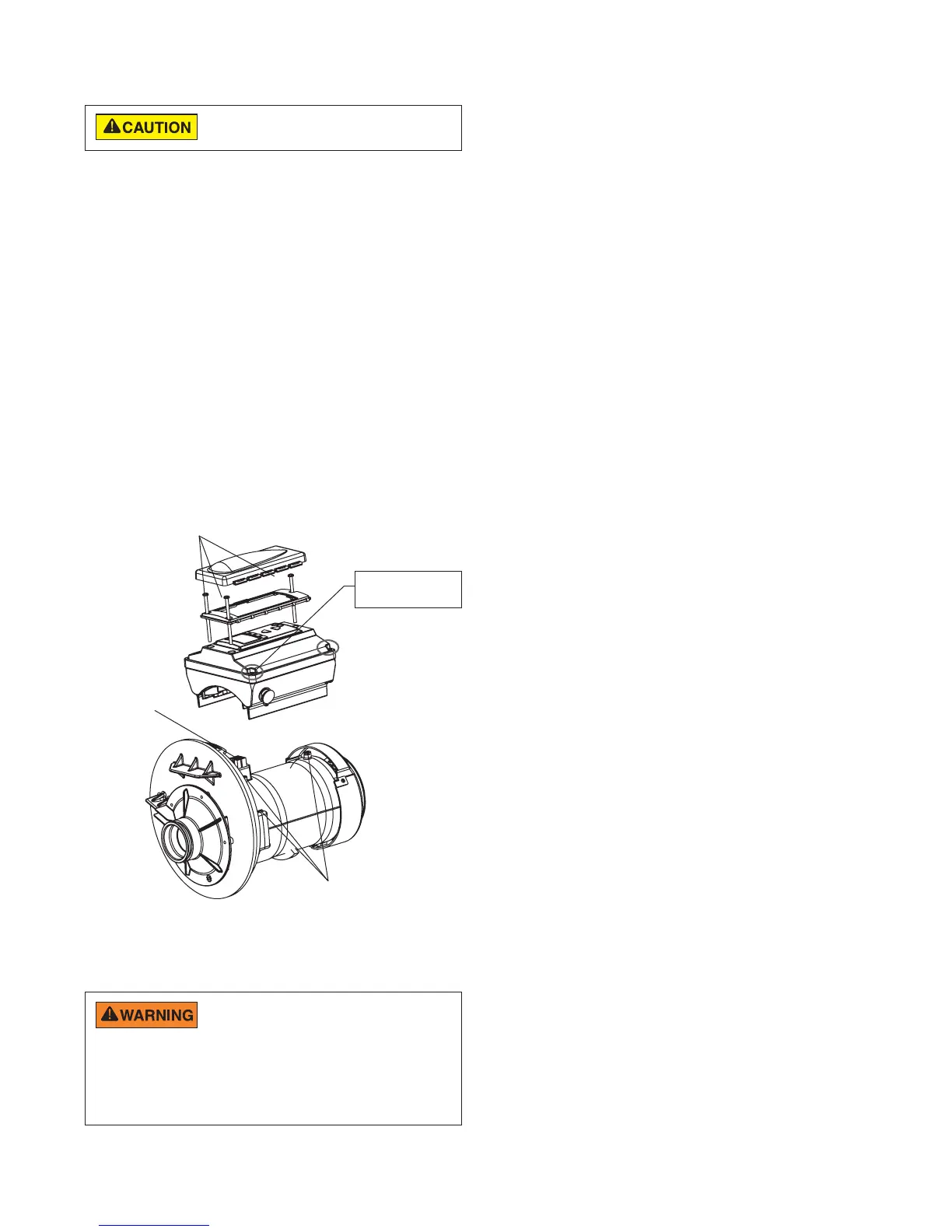

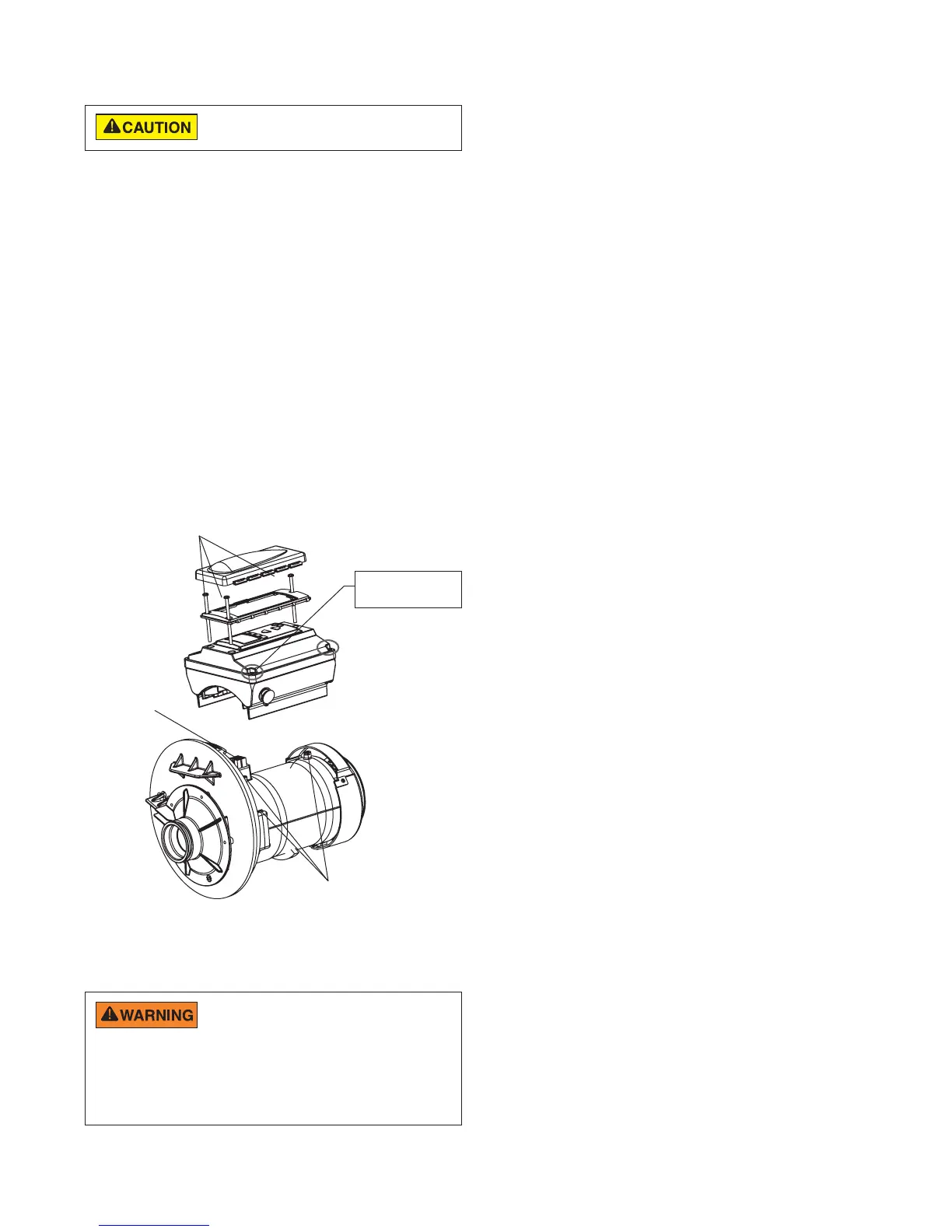

Drive Assembly Removal and Installation

To install the drive assembly onto the motor

assembly:

1. Be sure all electrical breakers and switches are

turned off before installing the drive.

2. Besurethatthegasketbetweenthedriveandmotor

isinplace.Itiscriticalinkeepingmoistureoutofthe

driveandmotor.Replacethegasketifdamaged.Do

notreassemblewithadamagedormissinggasket.

3. Verifythatthethree(3)orangemotorpostcapsare

in position before placing the drive on the motor

assembly(seeillustrationbelow).

4. Alignthedriveassemblywiththemotoradapterand

seat the drive on the motor assembly.

5. Secureandtightenthedriveassemblywiththethree

Phillips head screws.

DriveAssemblyandRemoval

Illustrated Parts View

FIRE and BURN HAZARD - The pump motor

may run at a high temperatures. To reduce the

risk of fire, do not allow leaves, debris, or foreign matter to collect

around the pump motor. To avoid burns when handling the motor, shut

off the motor and allow it to cool for 20 minutes before servicing. The

pump provides an automatic internal cutoff switch to protect the motor

from heat damage during operation.

Before installing this product, read and follow all

warning notices and instructions on page ii - iii.

Do not remove

these screws

PhillipsHead

Screw(3)

Adapter

Connector

andGasket

OrangeMotorPost

Caps(3)

Loading...

Loading...