35

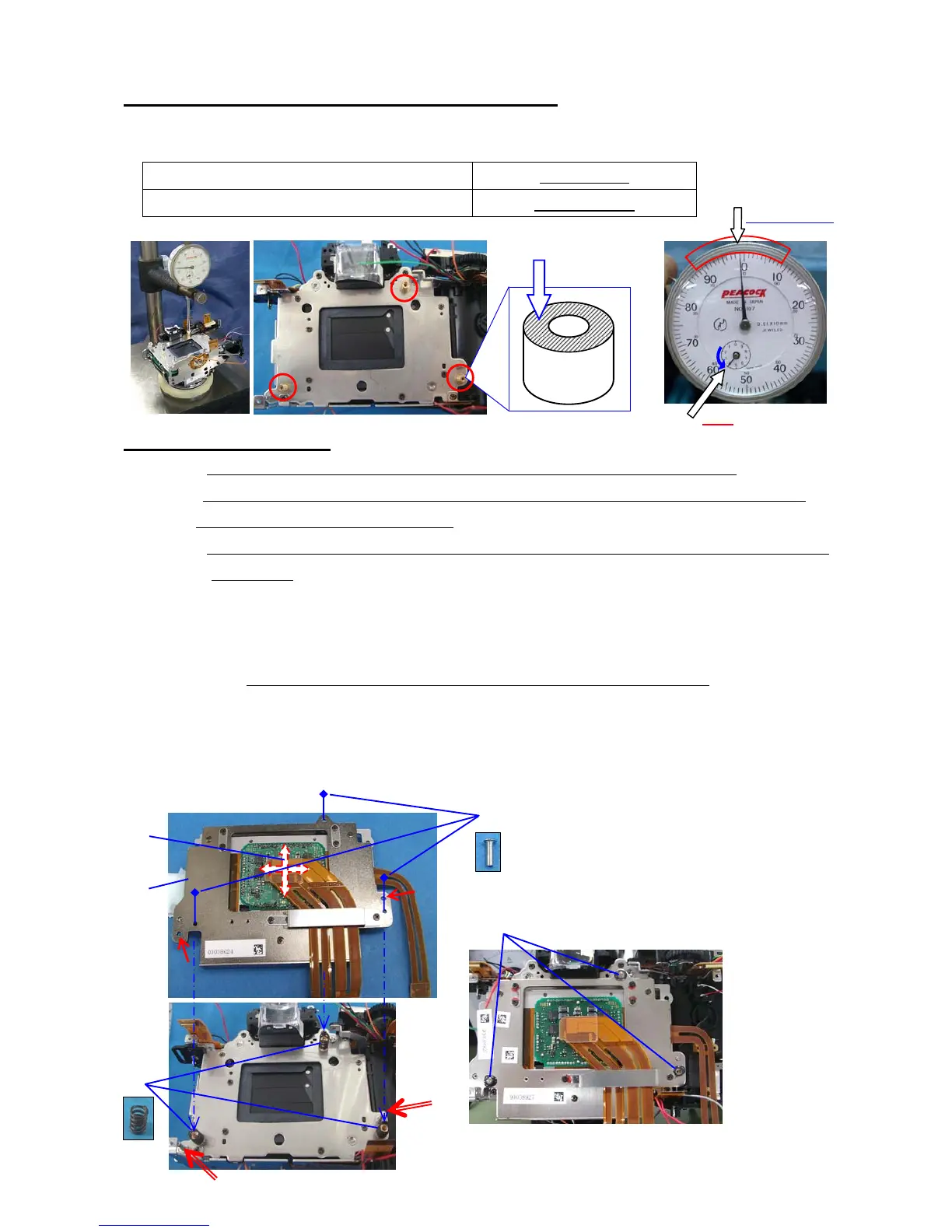

13. [CONFIRM] CCD BASE PLATE SUPPORT PILLAR

[Required equipment] Block gauge for 35mm, Dial gauge comparator, etc. (same as *istD or K100D )

① Measure height of the CCD base support pillar (3 places) from the mount surface as shown in the figure.

Tolerance (For 76830 only): 49.45±0.1 mm

With using Block gauge for 35mm (45.46mm):

+3.89~4.09 mm

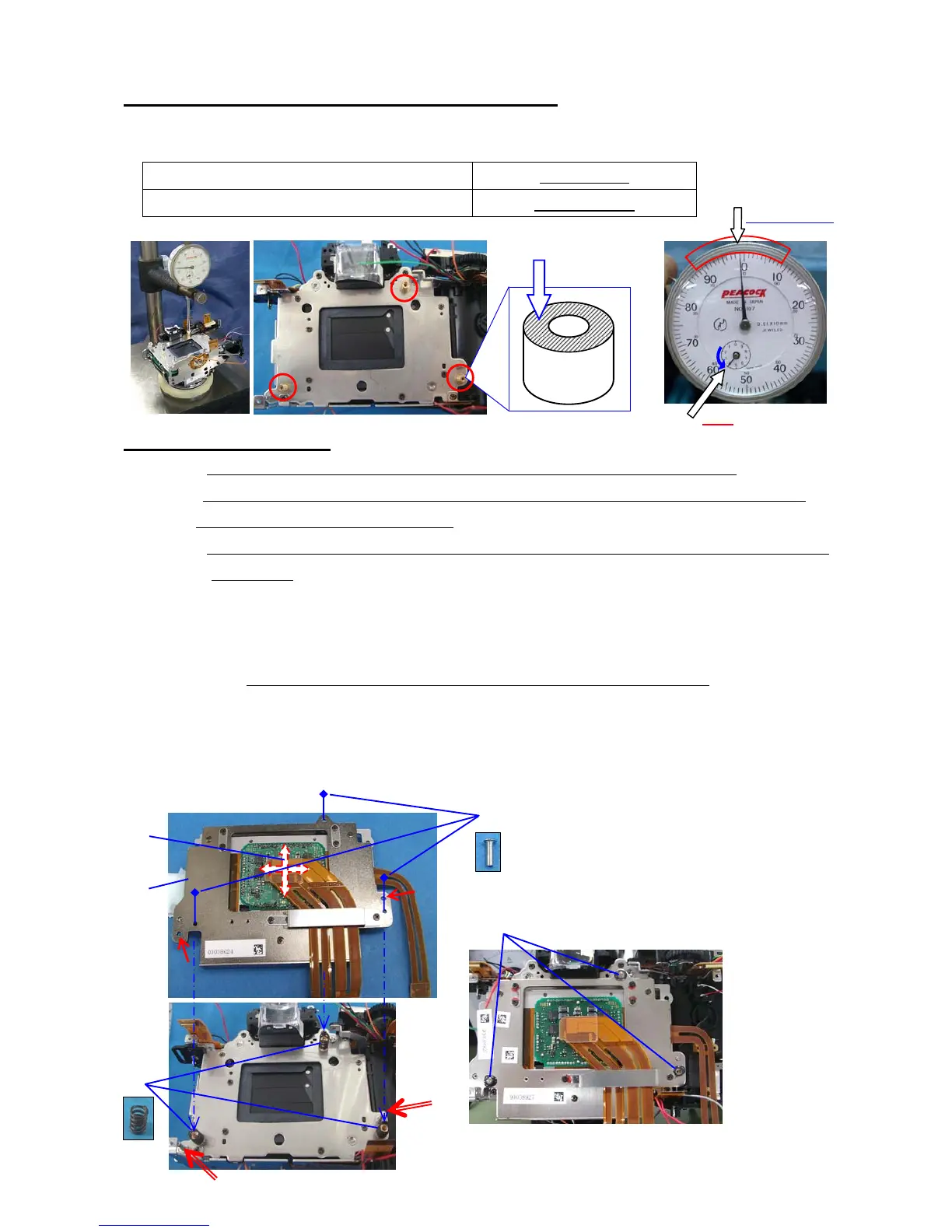

14. 0-C000 (SR/CCD block)

[Caution-1] CCD/SR block has strong magnet inside, therefore caution for adsorption of parts.

[Caution-2]Since a performance is spoiled, a CCD/SR block cannot be disassembled and also don't apply

the external pressure to a movable part

[Caution-3] The flex from SR/CCD should be take care carefully, otherwise it will effect the performance of

SR function.

[Caution-4] There is no scratch or dust on the CCD surface.

*To prevent the damage of SI-LED, attach mount cover. Then put downward.

① A32 Coil spring x3 – install to pillar.

② [Confirmation] Center plate must move up and down and right and left by own weight.

③ Arrange lead wire and flex then install CCD/SR block according to the guide pin of the plate.

[Caution] A32 must not come off and adsorption to magnet.

④ A31 adjusting screw x3 – Tighten A31 until stop while pressing to main body.

⑤ [Adjustment] Height of 0-C000, temporally adjustment by A31 x3 - Screw back two turns.

+3.

+0.89~1.09

④

③

①

②

⑤

Loading...

Loading...