106 SEBU8603-01

Maintenance Section

Turbocharger - Inspect

Check the start

ing motor for correct operation. Check

the electrical connections and clean the electrical

connections. Refer to the Systems Operation, Testing

and Adjusting

Manual, “Electric Starting System -

Test” for more information on the checking procedure

and for specifications or consult your Perkins dealer

or your Perki

ns distributor for assistance.

i04287011

Tu rb oc harger - Ins pe ct

Hot engine components can cause injury from

burns. Be

fore performing maintenance on the

engine, allow the engine and the components to

cool.

NOTICE

Turbocharger bearing failures can cause large quanti-

ties of oil to enter the air intake and exhaust systems.

Loss of engine lubricant can result in serious engine

damage.

Minor leakage of oil into a turbocharger under extend-

ed low idle operation should not cause problems as

long as a turbocharger bearing failure has not oc-

curred.

If a turbocharger failure is suspected do not operate

the engine. A failure of the turbocharger can be sig-

naled by significant loss of engine performance and

erratic RPM at no load. Also, large quantities of en-

gine oil could pass into the engine air intake. This oil

would have been seen as smoke from the engine ex-

haust. Applications that have a DPF installed will filter

theengineexhaust.

A visual inspection of the turbocharger or

turbochargers can minimize unscheduled downtime.

A visual inspection of the turbocharger or

turbochargers can also reduce the chance for

potential damage to other engine parts. Do not

inspect the engine with the engine in operation.

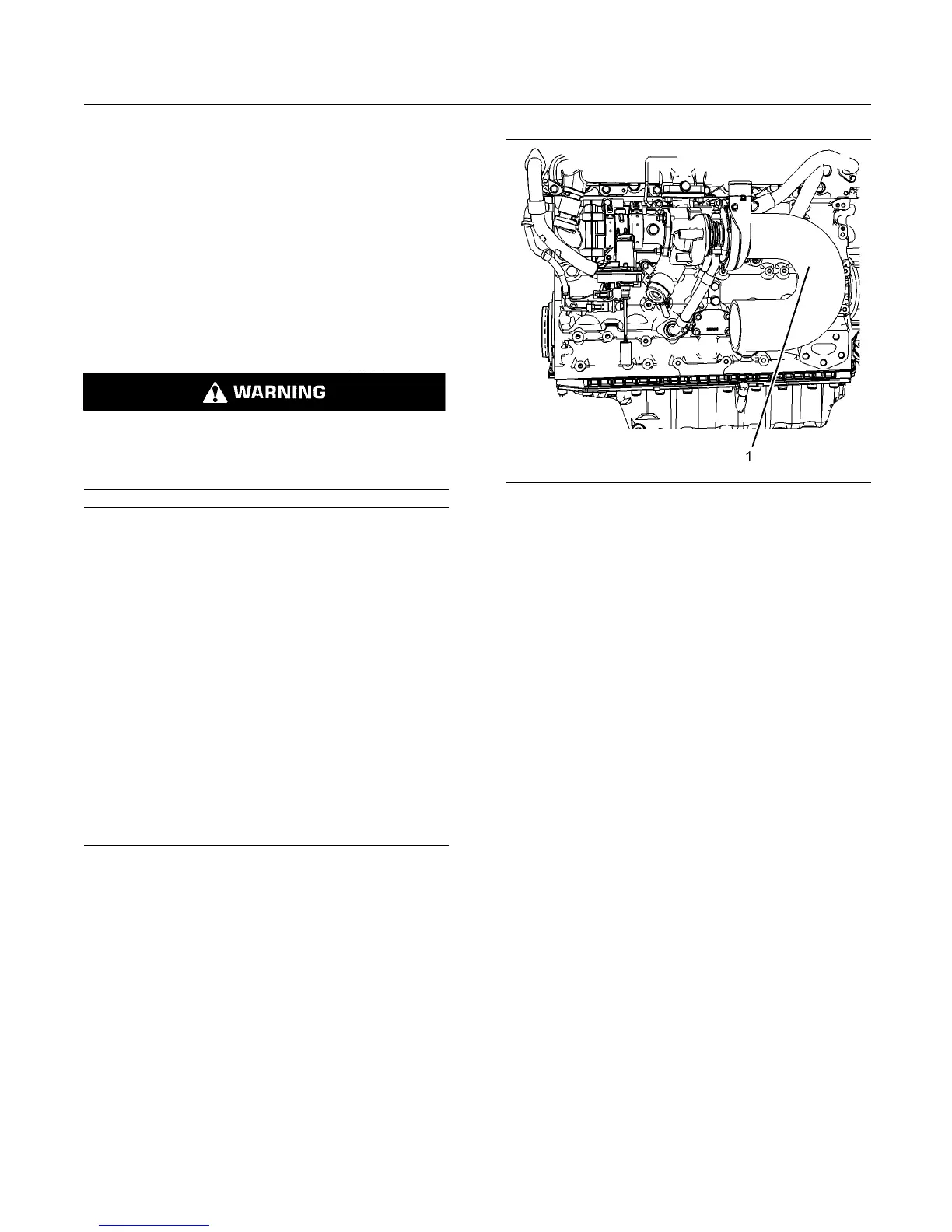

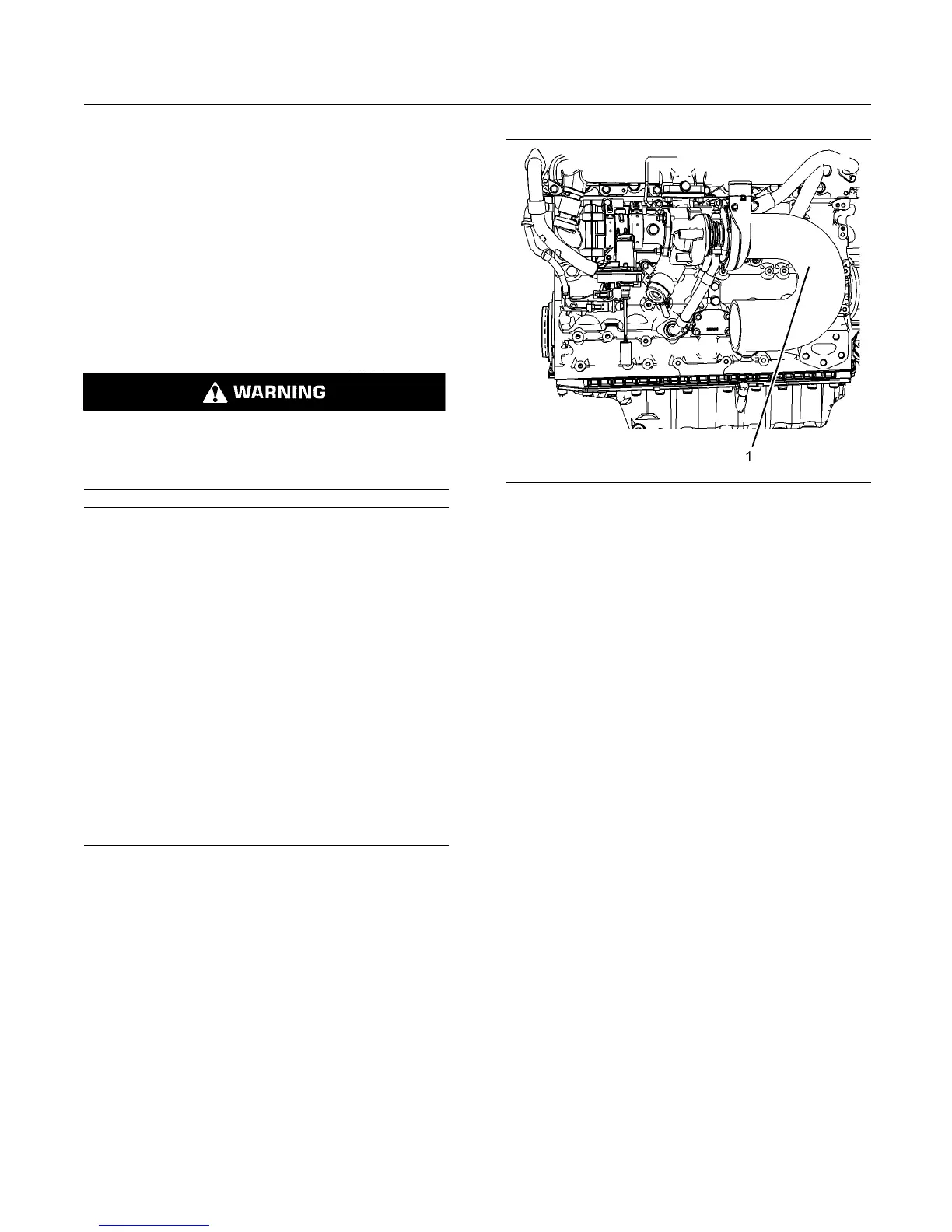

g02178129

Illustration 69

Typical example

1. Ensure that the turbocharger is clean and free from

dirt before removing components for inspection.

2. Remove the pipe from the turbocharger exhaust

outlet and remove the air intake pipe (1). Visually

inspect the piping for the presence of oil. Clean

the interior of the pipes in order to prevent dirt

from entering during reassembly.

3. Check for abnormal heat discoloration of the

turbocharger. Check for any loose bolts or any

missing bolts. Check for damage to the oil supply

line and the oil drain line. Check for cracks in

the housing of the turbocharger. Ensure that the

compressor wheel can rotate freely. Check for

signs of damage to the compressor wheel, or

contact of the compressor wheel to the body of

the compressor housing.

4. Check for the presence of oil. If oil is leaking from

the back side of the compressor wheel, there is a

possibility of a failed turbocharger oil seal.

The presence of oil may be the result of extended

engine operation at low idle. The presence of

oil may also be the result of a restriction of the

line for the intake air (clogged air filters), which

causes the turbocharger to slobber. For more

information, refer to Systems Operation, Testing,

and Adjusting, “Turbocharger - Inspect”.

Loading...

Loading...