SEBU8603-01 83

Maintenance Section

Cooling System Coolant (ELC) - Change

Flush

1. Flush the cool

ing system with clean water in order

to remove any debris.

2. Close the drai

n cock or install the drain plug in the

engine. Close the drain cock or install the drain

plug on the radiator.

NOTICE

Do not fill the cooling system faster than 5 L

(1.3 US gal) per minute, in order to avoid air locks.

Cooling system air locks may result in engine damage.

3. Fill the co

oling system with clean water. Install the

cooling system filler cap.

4. Start and

run the engine at low idle until the

temperature reaches 49 to 66 °C (120 to 150 °F).

5. Stop the

engine and allow the engine to cool.

Loosen the cooling system filler cap slowly in

order to relieve any pressure. Remove the cooling

system fi

ller cap. Open the drain cock or remove

the drain plug on the engine. Open the drain cock

or remove the drain plug on the radiator. Allow

the wat

er to drain. Flush the cooling system with

clean water.

Fill

1. Close

thedraincockorinstallthedrainplugonthe

engine. Close the drain cock or install the drain

plug on the radiator.

NOTI

CE

Do not fill the cooling system faster than 5 L

(1.3 US gal) per minute, in order to avoid air locks.

Cooling system air locks may result in engine damage.

2. Fil

l the cooling system with Commercial

Heavy-Duty Coolant. Add Supplemental Coolant

Additive to the coolant. For the correct amount,

re

fer to the Operation and Maintenance Manual,

“Fluid Recommendations” topic (Maintenance

Section) for more information on cooling system

sp

ecifications. Do not install the cooling system

filler cap.

3

.

S

tart and run the engine at low idle. Increase

the engine rpm to high idle. Operate the engine

in order to open the engine thermostat. This

p

rocedure will allow any air in the system to be

purged. Decrease the engine speed to low idle.

Stop the engine.

4. Maintain the co

olant level at the maximum mark

that is correct for your application.

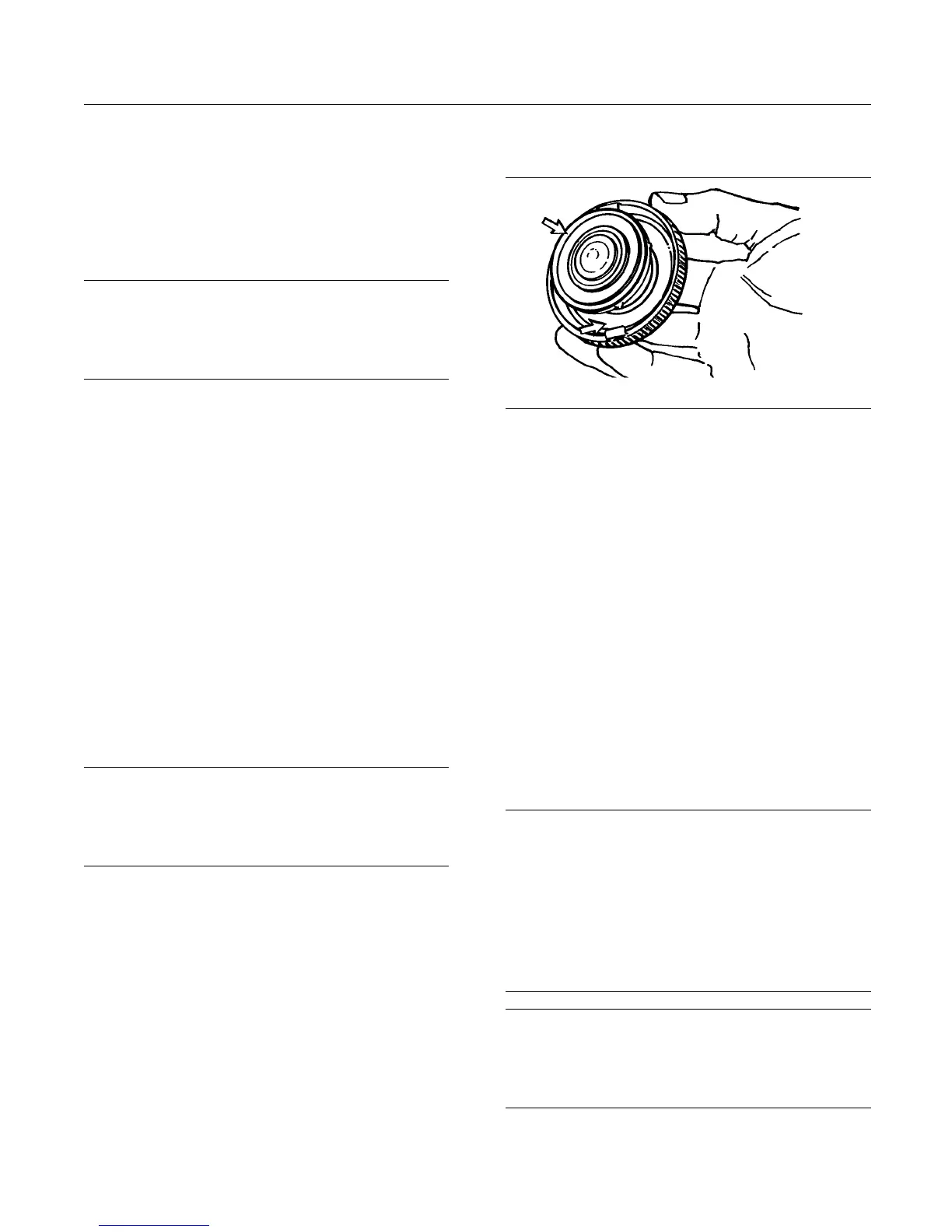

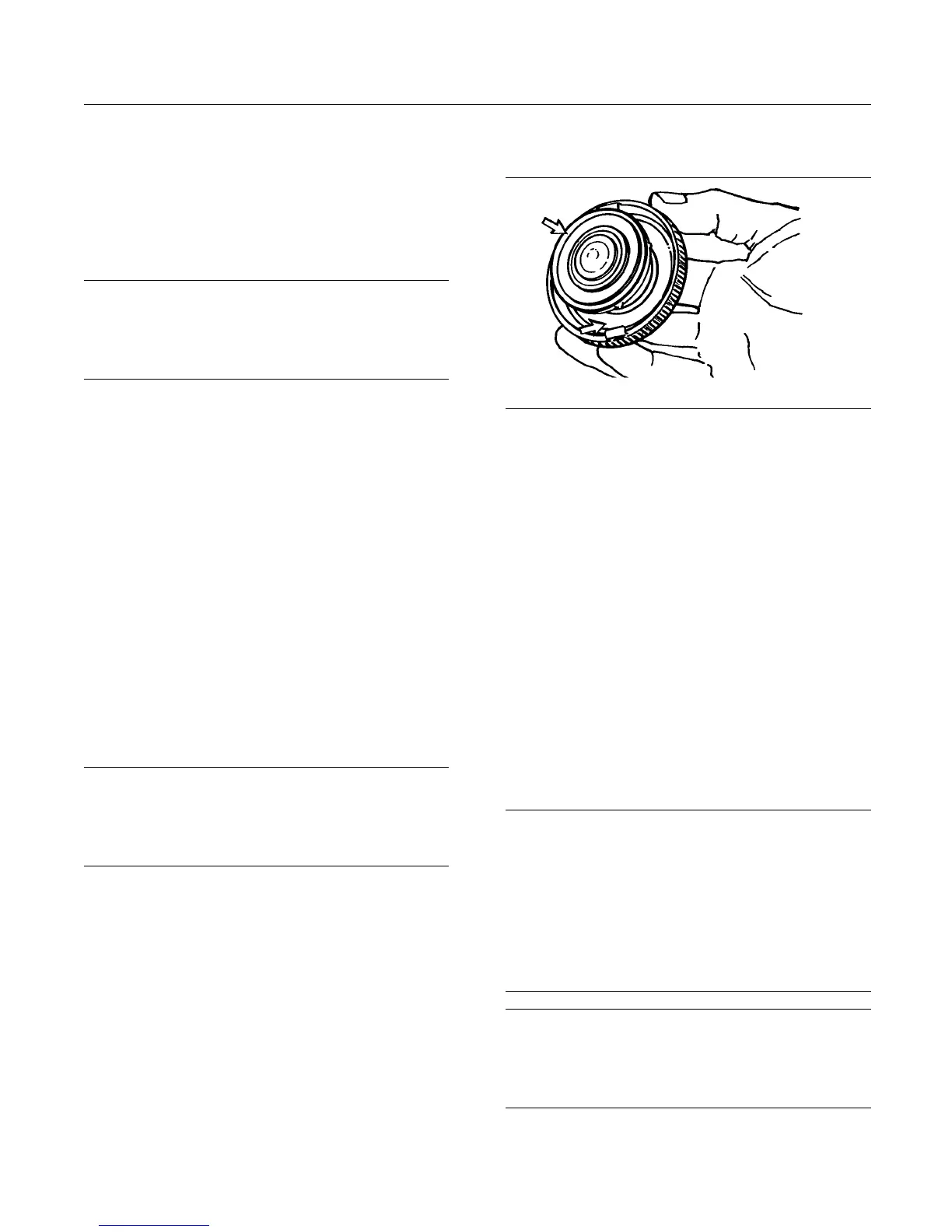

g00103639

Illustration 43

Filler cap

5. Clean the cooling system filler cap and inspect the

gasket. If the gasket is damaged, discard the old

filler cap and install a new filler cap. If the gasket

is not damaged, use a suitable pressurizing pump

in order to pressure test the filler cap. The correct

pressure is stamped on the face of the filler cap. If

the filler cap does not retain the correct pressure,

install a new filler cap.

6. Start the engine. Inspect the cooling system for

leaks and for correct operating temperature .

i04007109

Cooling System Coola nt (ELC)

-Change

NOTICE

Care must be taken to ensure that fluids are contained

during performance of inspection, maintenance, test-

ing, adjusting and repair of the product. Be prepared to

collect the fluid with suitable containers before open-

ing any compartment or disassembling any compo-

nent containing fluids.

Dispose of all fluids according to Local regulations and

mandates.

N

OTICE

Keep all parts clean from contaminants.

C

ontaminants may cause rapid wear and shortened

component life.

Clean the cooling system and flush the cooling

system before the recommended maintenance

interval if the following conditions exist:

Loading...

Loading...