30 SEBU8603-01

Operation Section

Lifting and Storage

i04195469

Product Lifting

(Clean Emissi

on Module)

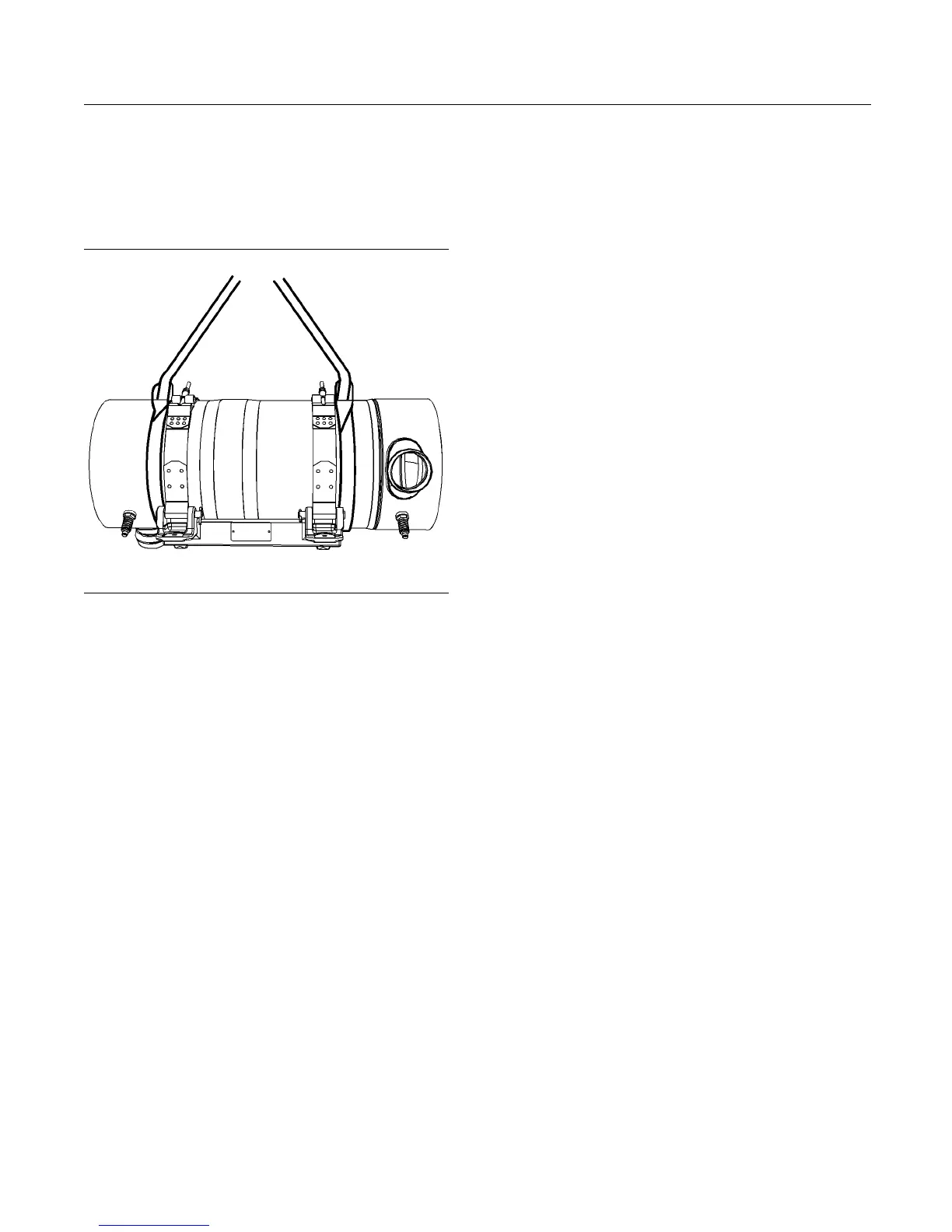

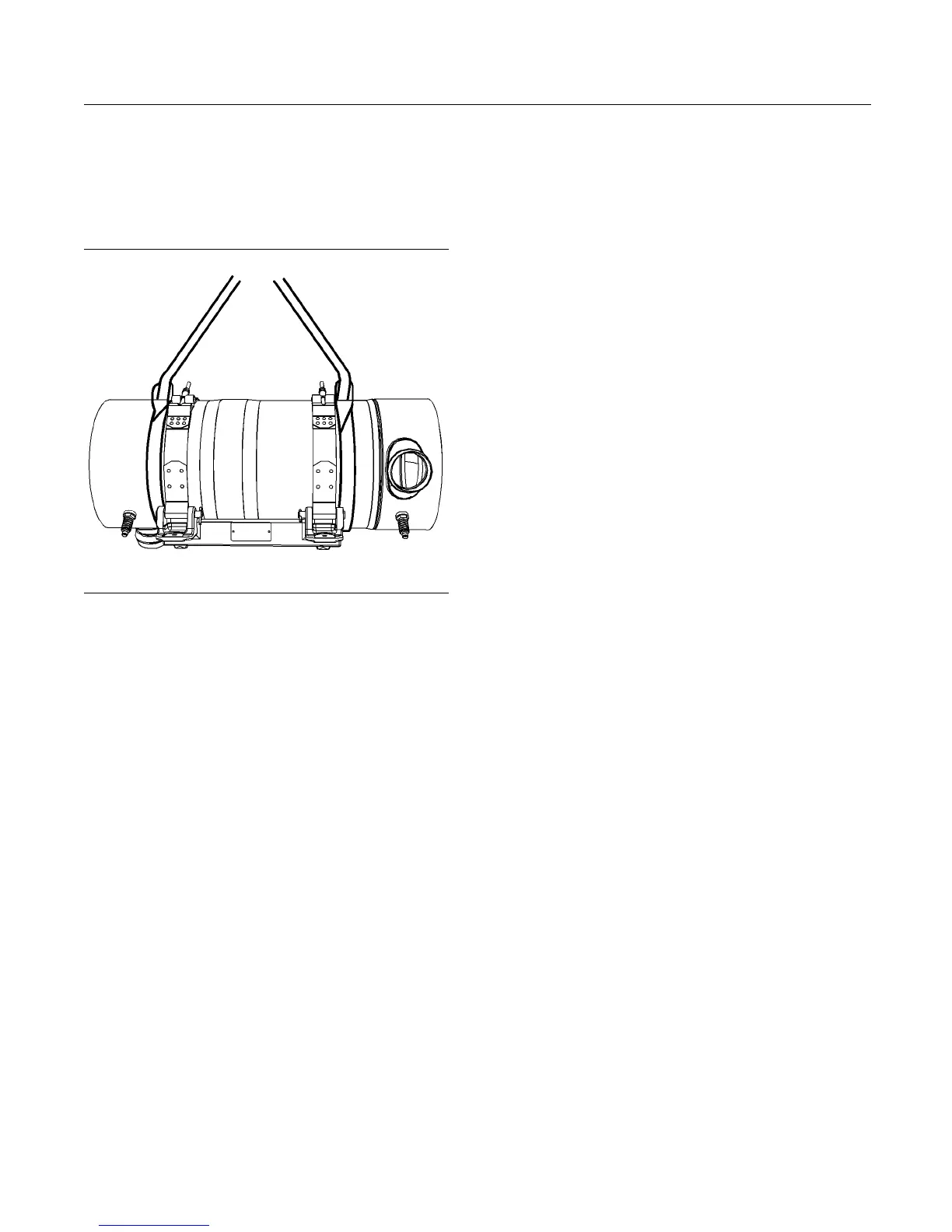

g02385036

Illustration 27

Ensure that the correct clothing is worn, refer to

this Operation and Maintenance Manual, “General

Hazard Information”.

The weight of the clean emission module (CEM)

when laden is approximately 50 kg (110 lb). Two

suitable double looped slings are required in order to

lift the CEM. Also a suitable hoist will be required in

order to remove and install the assembly.

The slings must be attached to the CEM in the

positions as shown in illustration 27.

Ensure that the slings only contact the body of the

CEM. A test lift may be required in order to achieve

the correct balance of the assembly.

Some applications may require a frame or jig in order

to lift the CEM. A frame or jig must only be connected

to the cradle of the CEM. Refer to the OEM for more

information.

i04084189

Product Storage

(Engine and Af

tertreatment)

Perkins are not responsible for damage which may

occur when an engine is in storage after a period in

service.

Your Perkins dealer or your Perkins distributor can

assist in pr

eparing the engine for extended storage

periods.

Condition for Storage

The engine

must be stored in a water proof building.

The building must be kept at a constant temperature.

Engines that are filled with Perkins ELC will have

coolant p

rotectiontoanambienttemperatureof

−36° C (−32.8° F). The engine must not be subjected

to extreme variations in temperature and humidity.

Storage Period

An engin

e can be stored for up to 6 months provided

all the recommendation are adhered to.

Storag

e P rocedure

Keep a record of the procedure that has been

comple

ted on the engine.

Note: Do not store an engine that has biodiesel in

the fu

el system.

1. Ensure that the engine is clean and dry.

a. If the engine has been operated using biodiesel,

thesystemmustbedrainedandnewfilters

inst

alled. The fuel tank will require flushing.

b. Fill the fuel system with an ultra low sulfur fuel.

For m

ore information on acceptable fuels refer

to this Operation and Maintenance Manual,

“Fluid recommendations”. Operate the engine

for

15 minutes in order to remove all biodiesel

from the system.

2. Dra

in any water from the primary filter water

separator. Ensure that the fuel tank is full.

3. Th

e engine oil will not need to be drained in

order to store the engine. Provided the correct

specification of engine oil is used the engine

ca

n be stored for up to 6 months. For the

correct specification of engine oil refer to this

Operation and Maintenance Manual, “Fluid

r

ecommendations”.

Loading...

Loading...