68 SEBU8603-01

Maintenance Section

Refill Capacities

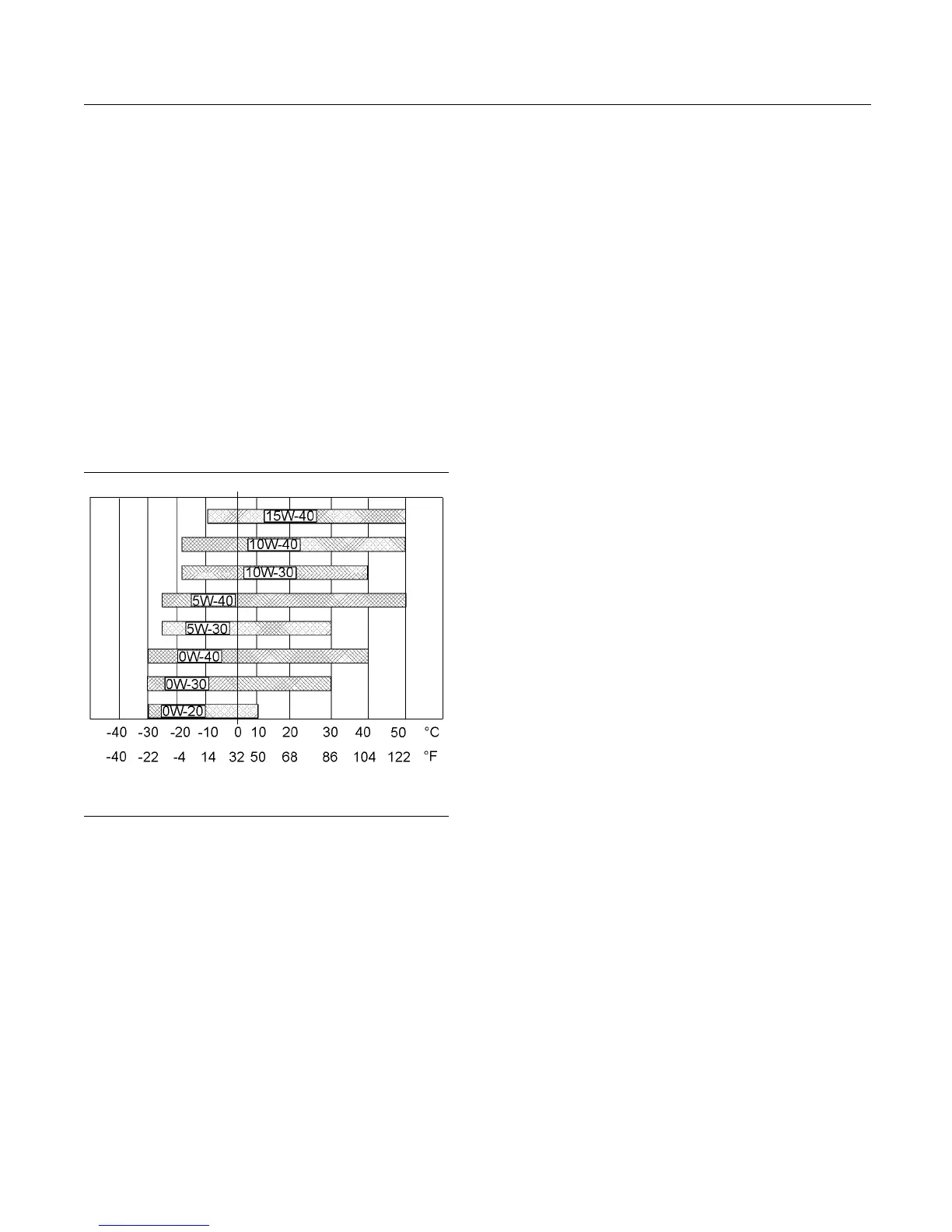

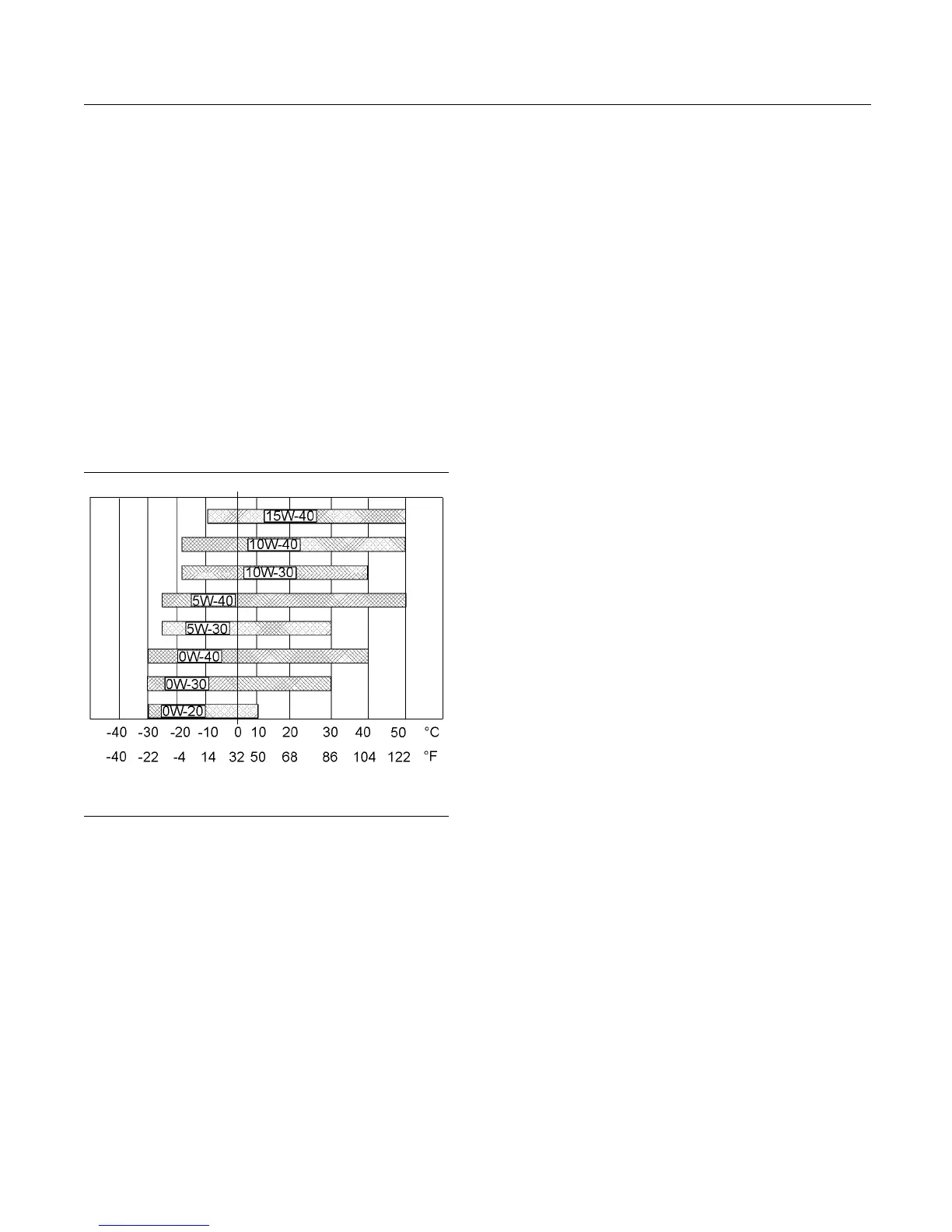

Lubricant Visc

osity Recommendations

for Direct Injection (DI) Diesel Engines

The correct SA

E viscosity grade of oil is determined

by the minimum ambient temperature during

cold engine start-up, and the maximum ambient

temperature

during engine operation.

Refertoillustration37(minimumtemperature)in

order to det

ermine the required oil viscosity for

starting a cold engine.

Refer to ill

ustration 37 (maximum temperature) in

order to select the oil viscosity for engine operation at

the highest ambient temperature that is anticipated.

Generally, use the highest oil viscosity that is

available to meet the requirement for the temperature

at start-u

p.

g02210556

Illustration 37

Lubricant Viscosities

Supplemental heat is recommended for cold soaked starts below

the m inimum am bient temperature. S upplemental heat may be

required for cold soaked starts that ar e above the minimum

temperature that is stated, depending on the parasitic load and

other factors. Cold soak ed starts occur when the engine has not

been operated for a period of time. This interval will allow the oil to

become more viscous due to cooler am bient temperatures.

Aftermarket Oil Additives

Perkins does not recommend the use of aftermarket

additives in oil. It is not necessary to use aftermarket

additives in order to achieve the engines maximum

service life or rated performance. Fully formulated,

finished oils consist of base oils and of commercial

additive packages. These additive packages are

blended into the base oils at precise percentages in

order to help provide finished oils with performance

characteristics that meet industry standards.

There are no ind

ustry standard tests that evaluate

the performance or the compatibility of aftermarket

additives in finished oil. Aftermarket additives may

not be compati

blewiththefinished oils additive

package, which could lower the performance of the

finished oil. The aftermarket additive could fail to mix

with the finis

hed oil. This failure could produce sludge

in the crankcase. Perkins discourages the use of

aftermarket additives in finished oils.

To achieve the best performance from a Perkins

engine, conform to the following guidelines:

•

See the appropriate “Lubricant Viscosities”. Refer

totheillustration37inordertofind the correct oil

viscosity

grade for your engine.

•

At the specified interval, service the engine. Use

new oil and

install a new oil filter.

•

Perform maintenance at the intervals that are

specified

in the Operation and Maintenance

Manual, “Maintenance Interval Schedule”.

Oil anal

ysis

Some engines may be equipped with an oil sampling

valve. I

f oil analysis is required, the oil sampling valve

is used to obtain samples of the engine oil. The oil

analysis will complement the preventive maintenance

progra

m.

The oil analysis is a diagnostic tool that is used to

determ

ine oil performance and component wear

rates. Contamination can be identified and measured

by using oil analysis. The oil analysis includes the

follo

wing tests:

•

The Wear Rate Analysis monitors the wear of the

engin

es metals. The amount of wear metal and

type of wear metal that is in the oil is analyzed. The

increase in the rate of engine wear metal in the

oil i

s as important as the quantity of engine wear

metal in the oil.

•

Test

s are conducted in order to detect

contamination of the oil by water, glycol, or fuel.

•

The

Oil Condition Analysis determines the loss of

the oils lubricating properties. An infrared analysis

is used to compare the properties of new oil to the

pro

perties of the used oil sample. This analysis

allows technicians to determine the amount of

deterioration of the oil during use. This analysis

al

so allows technicians to verify the performance

of the oil according to the specification during the

entire oil change interval.

Loading...

Loading...