Mixing Pump PFT G4

Operation

2007-09-05 41

Check the mortar consistency

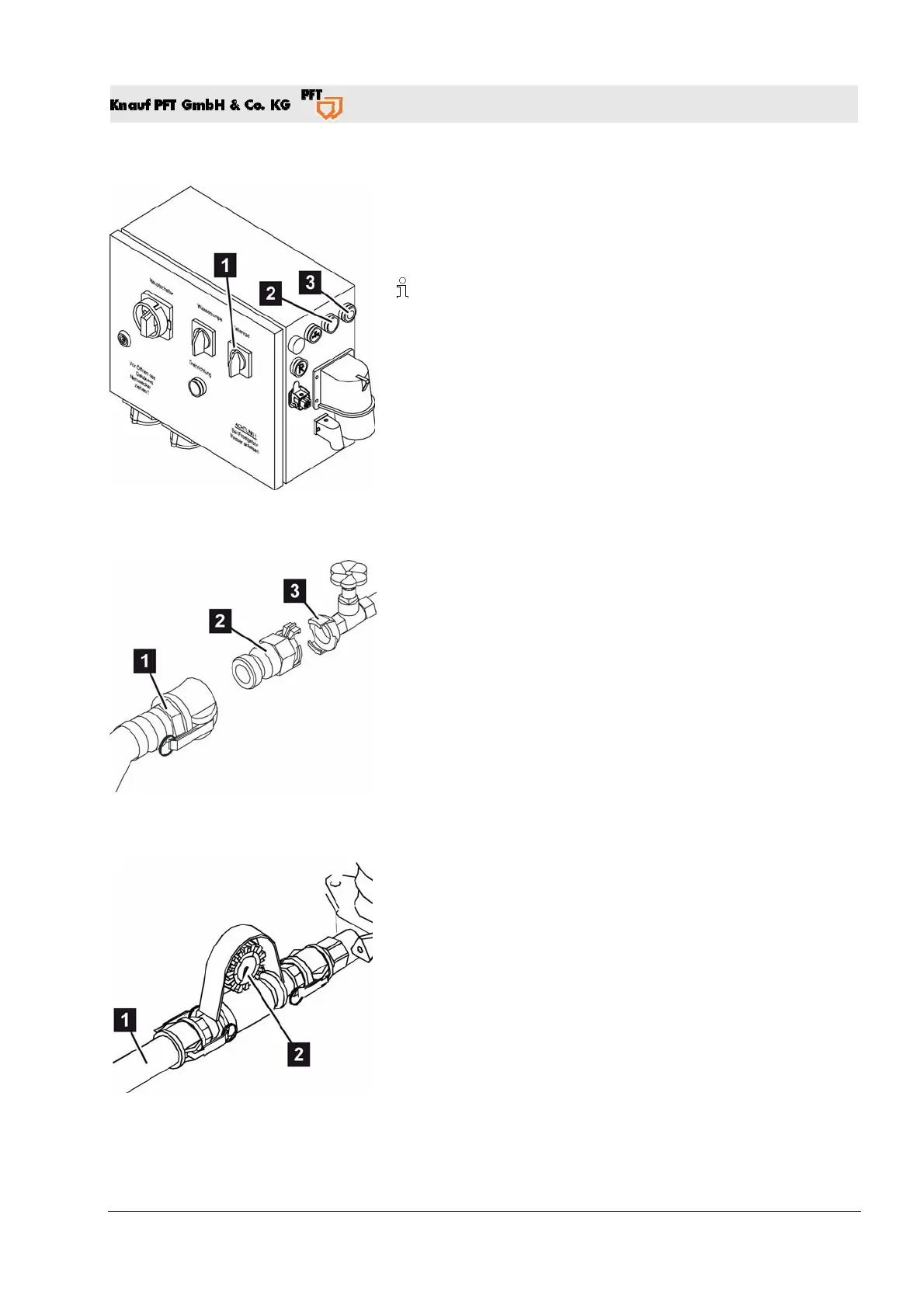

Fig. 30: Controls

5. Position the selector switch for cellular wheel (Fig. 30/1)

"Manual-O-Auto" to "AUTO".

6. Switch on the machine via the green pushbutton (Fig. 30/2).

The mortar will run out of the material connection.

7. Check the consistency of the mortar.

Correct mortar consistency is achieved when the material

merges on the surface being sprayed (we recommend applying

from top to bottom on wall surfaces). If the water quantity is

insufficient, uniform mixing and spraying is no longer ensured.

This can cause blockage in the hose and increased wear on the

pumps.

8. Switch off the machine via the red pushbutton (Fig. 30/3).

Preparing the mortar hose

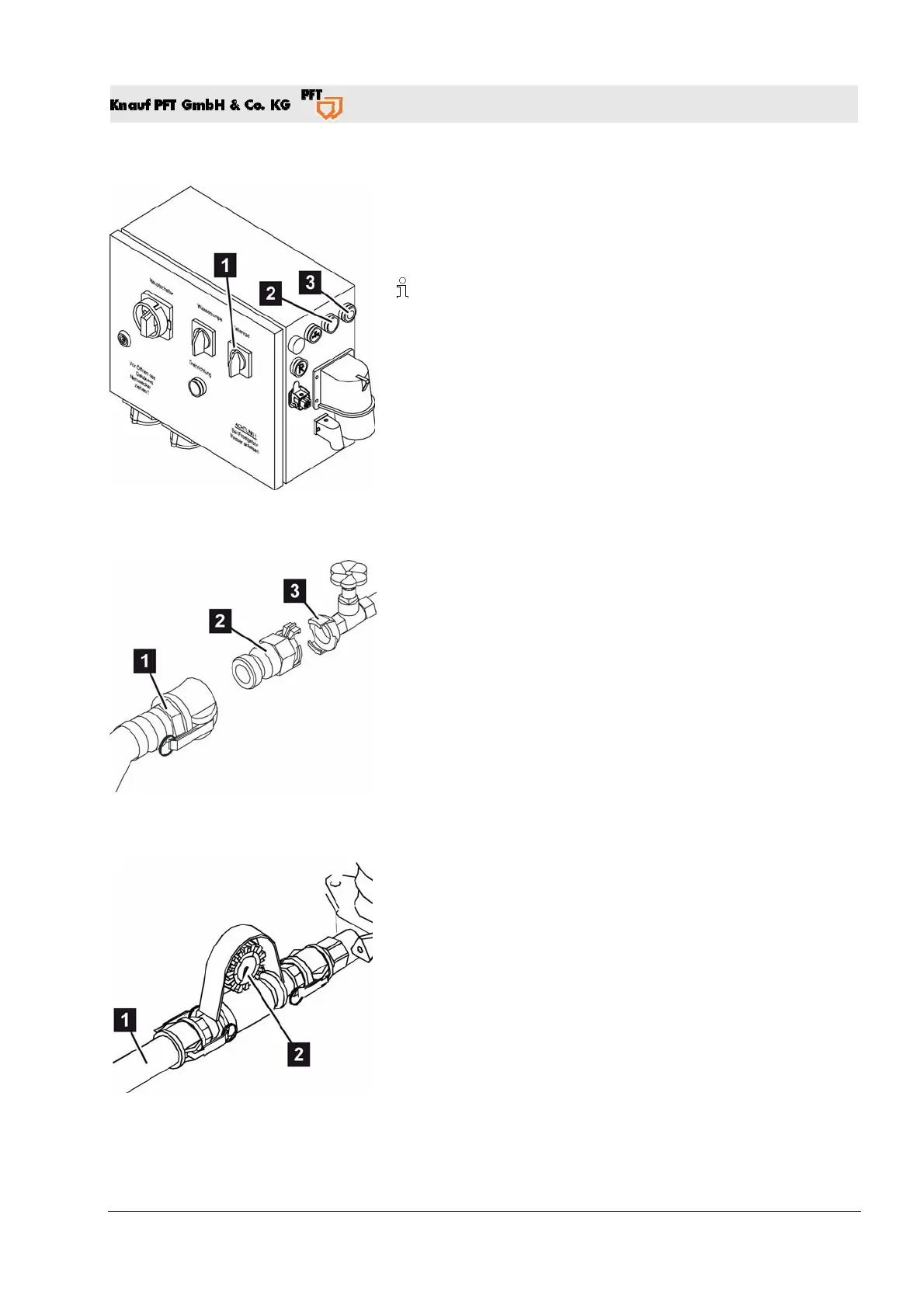

Fig. 31: Preparing the mortar hose

9. Connect the plaster component (Fig. 31/2) on the water

removal valve (Fig. 31/3).

10. Connect the motor hose (Fig. 31/1) and water.

11. Take off the motor hose and plaster component again and

disconnect.

12. Completely empty the mortar hose.

13. Pre-lubricate the mortar hose with approximately 2 liters of

wallpaper paste.

Connecting the mortar hose

Fig. 32: Connecting the mortar hose

14. Connect the mortar hose (Fig. 32/1) to the mortar pressure

manometer (

Fig. 32/2).

15. Switch on the machine via the "Operation ON" button and let

the machine run until mortar escapes at the end of the mortar

hose.

Loading...

Loading...