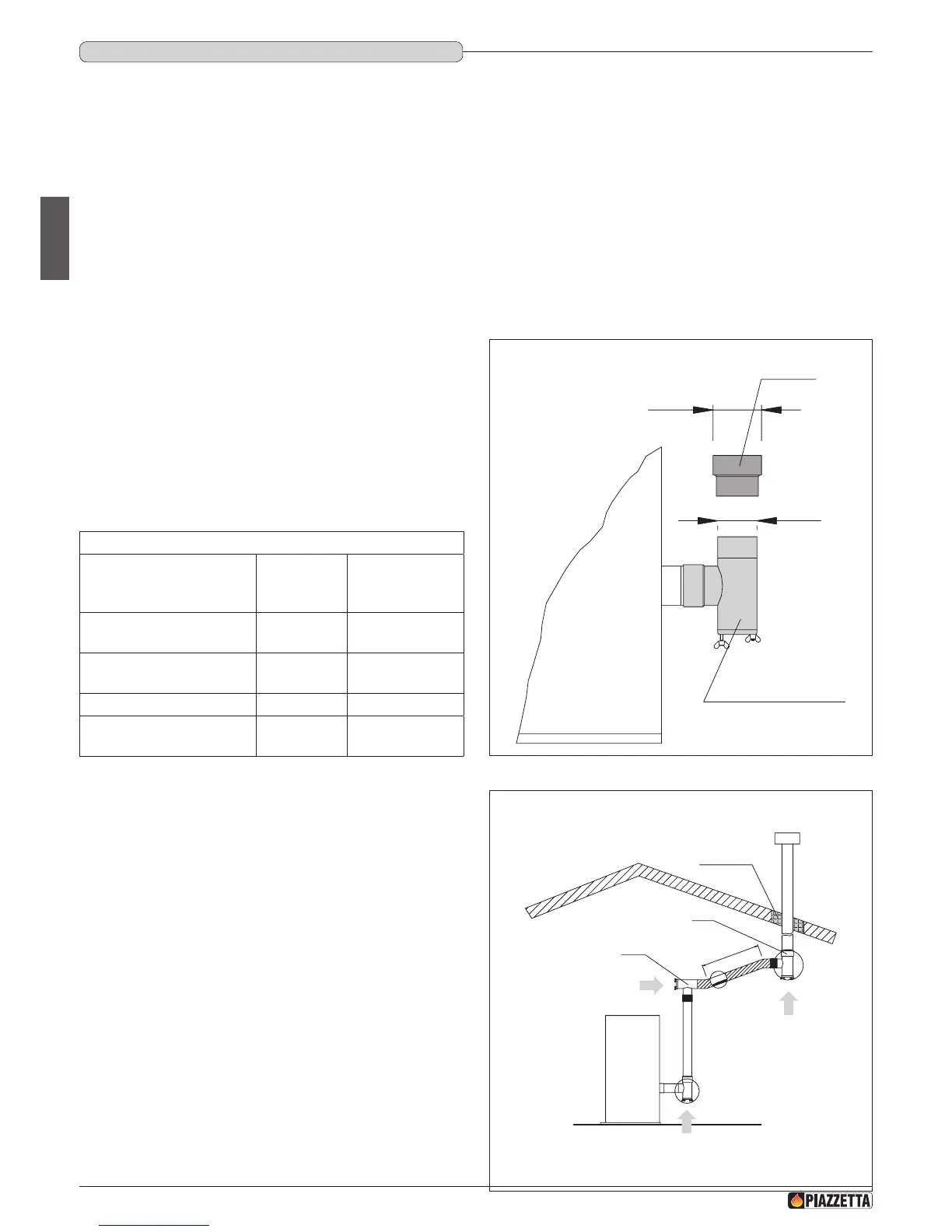

Ø100mm

Ø80mm

STRAIGHT REDUCER

Ø80>Ø100

TEE WITH SEALING PLUG

DIRECTION

OF CLEANING

DIRECTION OF CLEANING

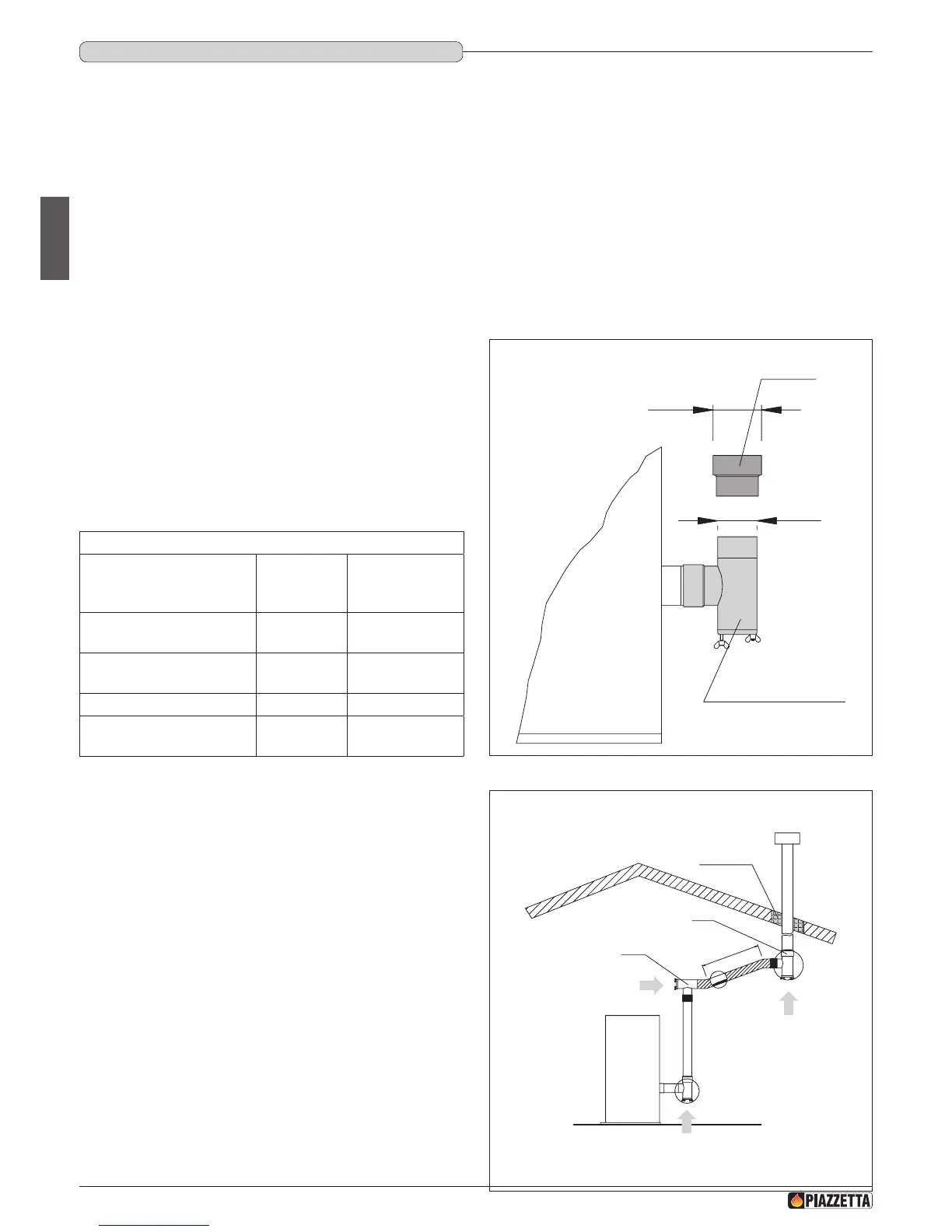

DIRECTION

OF CLEANING

TEE

TEE

INSULATING

MATERIAL

Max. 2m

(min. 3%)

Fig. 17

Fig. 18

a The pellet stove is not the same as other stoves. It has a forced draught of ue gas by a fan, which keeps the rebox in a vacuum

and the entire ueway slightly pressurised. For this reason the ue must be completely airtight and correctly installed to ensure both

trouble-free operation and user safety.

• The ueway must be made by specialised personnel or rms, as outlined below.

• The ue must be installed in such a way as to guarantee that periodic cleaning can be carried out without dismantling any parts whatsoever.

• Pipes should always be sealed with silicone (not cement-based sealants) or specially adapted gaskets/seals, which retain their strength and

elasticity at high temperatures (250°C), and should be xed with 3.9 mm ø self-tapping screws.

a Using the relative pipe clips, x the ue to the wall so that it does not weigh on the smoke fan.

d Do not install dampers or valves that could block the passage of ue gas.

d Do not connect to a ueway into which other appliances (boilers, extractor hoods, etc.) discharge fumes or vapours.

DT2010229-04

1.10 FLUEwAy

Pipes and maximum usable lengths

Pipes of painted aluminium-clad steel (minimum thickness 1.5 mm),

stainless steel (AISI 316) or enamelled steel (minimum thickness 0.5

mm) with a nominal diameter of 80 or 100 mm (for pipes which run

inside the ue maximum diameter 150 mm) can be used.

The male-female connectors must have a minimum length of 50 mm.

The diameter of the pipes depends on the type of installation. The stove

was designed to take 80 mm diameter pipes but, as shown in Table

1, in some cases the use of double-lined 100 mm diameter pipes is

recommended.

TABLE 1 PIPE LENGTH

TYPE OF INSTALLATION

WITH 80 mm

DIAMETER

PIPE

WITH DOUBLE-

WALLED 100 mm

DIAMETER PIPE

Maximum length

(with three 90° bends)

4.5 m 8 m

For installations more than

1200 m above sea level

- Required

Maximum number of bends 3 4

Length of horizontal sections

with minimum 3% gradient

2 m 2 m

a Losses in pressure associated with a 90° bend can be compared

to those incurred by one metre of pipe. An inspectable union-

tee can be considered equivalent to a 90° bend.

EXAMPLE: if installing a section greater than 4.5 m in length with

80 mm diameter pipe, calculate the maximum usable length in the

following ways:

- If a maximum of three 90° bends are used, the maximum length of

the section will be 4.5 m.

- If a maximum of two 90° bends are used and bearing in mind that a

90° bend can be replaced by one metre of pipe, the maximum length

of the section will be 4.5m+1m=5.5m.

- If a maximum of one 90° bend is used and bearing in mind that a 90°

bend can be replaced by one metre of pipe, the maximum length of

the section will be 4.5m+1m+1m=6.5m.

Where 100 mm diameter pipe must be used, connect it to the stove ue

outlet with a 80 mm union-tee then use a 80 mm 100 mm adaptor (not

supplied by Piazzetta) (Fig. 17).

H072047UK0 / DT2001513 – 04

10

Loading...

Loading...