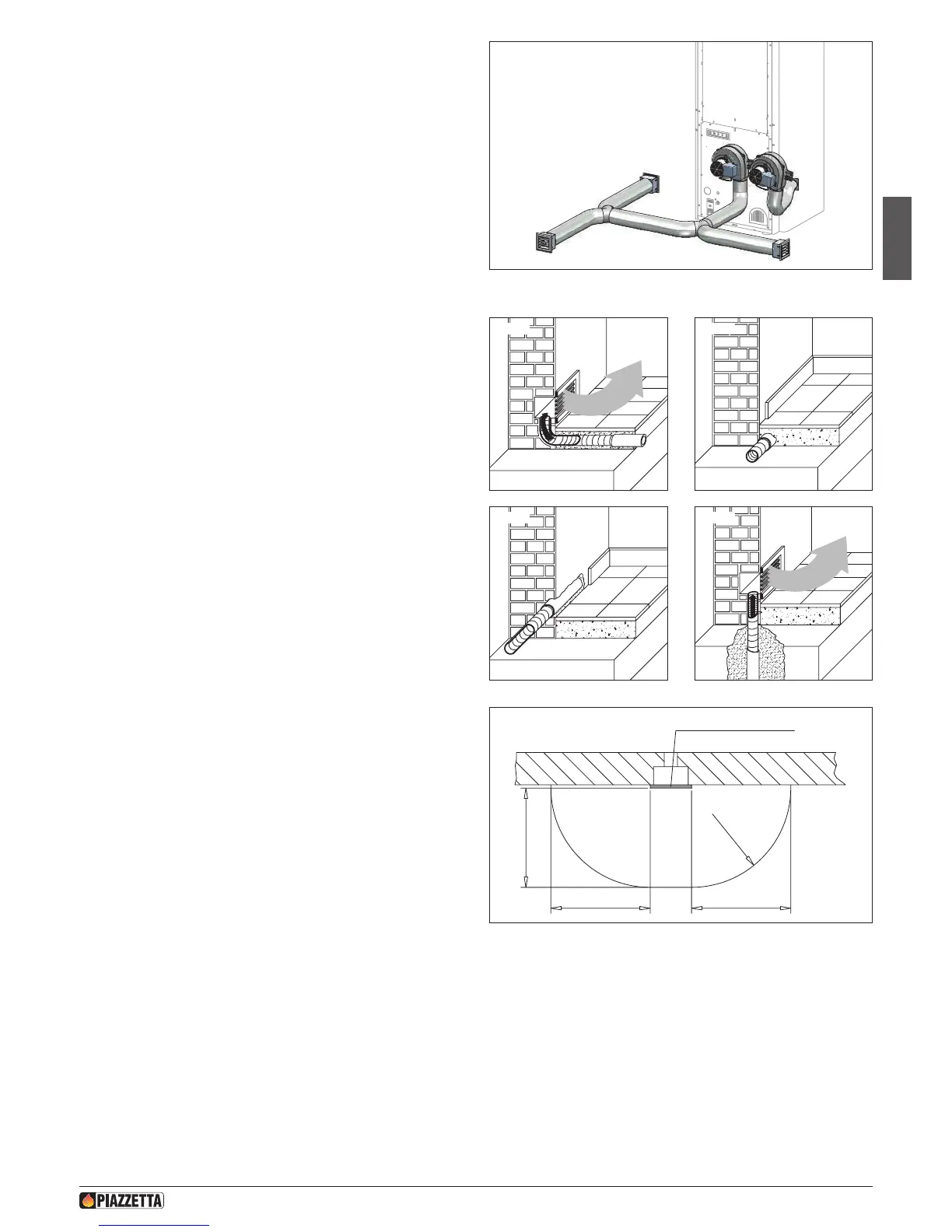

Solution 4 - Fig. 43:

Extending the previous solution with the appliance installed in the room

to be heated and heat directed to the front and rear of the appliance

with doubling-up using a second Y element at the rear as shown.

a For the example shown in Figure 43, you can install an outlet

with closure for the shortest section allowing for some of the

air to be released, without ever closing completely to prevent

overheating.

Wall and oor ducting - Fig. 44 / 47

For efcient ducted heat distribution:

- Lag the hose with a 2 cm thick insulation (e.g. mineral bre, ceramic

bre, rock bre) to limit heat loss and to guarantee a sufciently warm

air temperature.

- The insulation must have a specic weight equal to or more than

50 kg/m³ with working temperature limit of at least 250°C. Thermal

conductivity λ (100°C) ≤ 0,050 W/mK.

- Material with code “AGI Q132” or “DIN 18895” is allowed for thermal

insulation.

a If the insulating material is not enclosed under the oor or

within the walls, it must be xed to the surface with suitable

fastenings at intervals of 30 cm.

A few examples of how the hose can be installed in walls or oors are

given to the side.

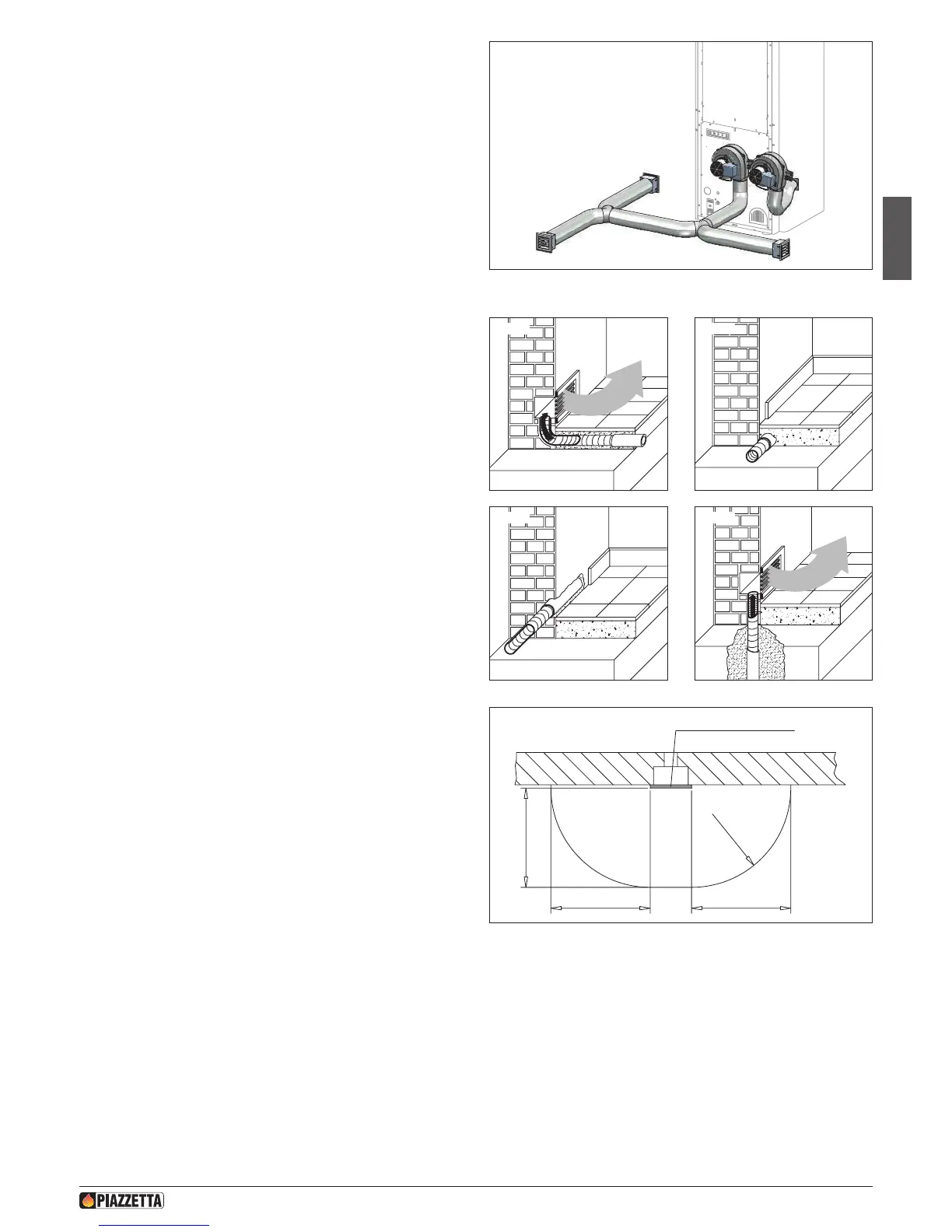

Hot air outlet vent radiation area (mm) - Fig. 48

A safety area must be ensured around the hot air outlet vent within

which there must be no ammable objects (furniture, carpets, curtains,

etc.) or heat sensitive materials (wood, plastic, etc.).

The diagram to the side shows the measurements for this safety area,

which includes 600 mm from the upper edge of the vent.

a If the oor is ammable, the hot air outlet vents must be

located at least 200 mm from the oor.

Fig. 43

R600

600

600600

HOT AIR OUTLET VENT

Fig. 44 Fig. 45

Fig. 46 Fig. 47

Fig. 48

H072047UK0 / DT2001513 – 04

23

Loading...

Loading...