MAINTENANCE.

1. Check the cylinder to be sure it is securely mounted.

2. Check the cylinder for the ICC identification number and for the date of the last FAA inspection and test.

3. If cylinder is completely empty it must be completely disassembled and inspected in an FAA or

manufacturer approved facility before recharging.

4. Refer to FAA Manual AC 43.13-1A for more details.

REMOVAL OF OUTLETS.

1. Make sure the control valve is in the full off position.

2. Connect a mask or connector to the valve to release any pressure.

3. Using a suitable spanner wrench, remove the outlet.

4. l~e outlet can now be removed from the low pressure fitting.

INSTALLATION OF OUTLETS.

1. Apply sealant (Permacel 412) to the male end of the fitting.

2. Install the outlet to the regulator extension with a suitable spanner wrench.

3. Torque the fittings into the outlets approximately 30 inch-pounds. Do not over torque as this could damage

the outlet.

PURGING OXYGEN SYSTEM

The system should be purged whenever the cylinder pressure falls below 50 psi or if any lines are left open for

any length of time. Also, if the bottle is left at below 200 psi it may develop odors from bacterial growth. This

will make it necessary to purge the system. Use the following procedures:

— CAUTION —

WHEN PERFORMING THIS OPERATION MAKE SURE THE AREA IS A

NO SMOKING AREA, AND IT IS AS CLEAN AS POSSIBLE OF OIL AND

DIRT.

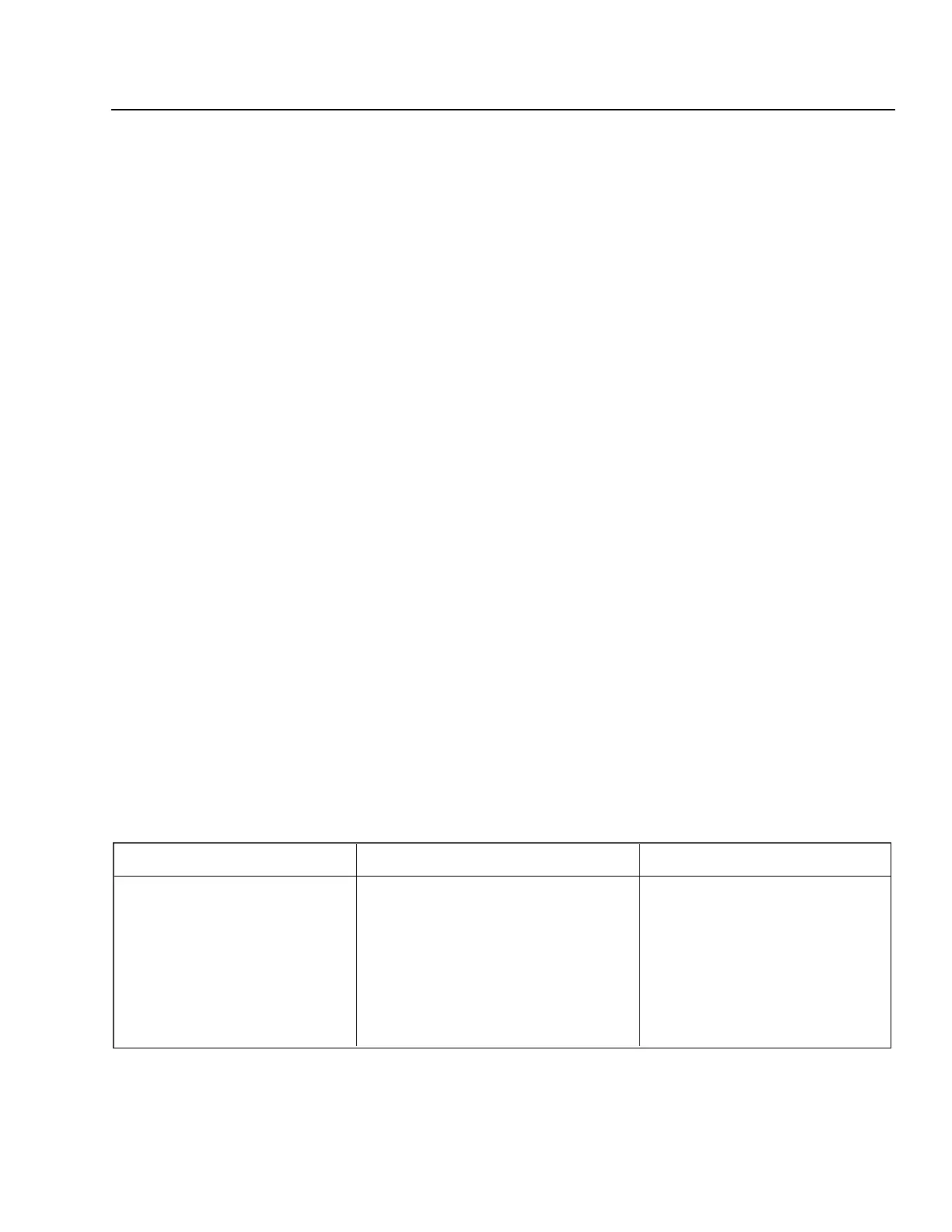

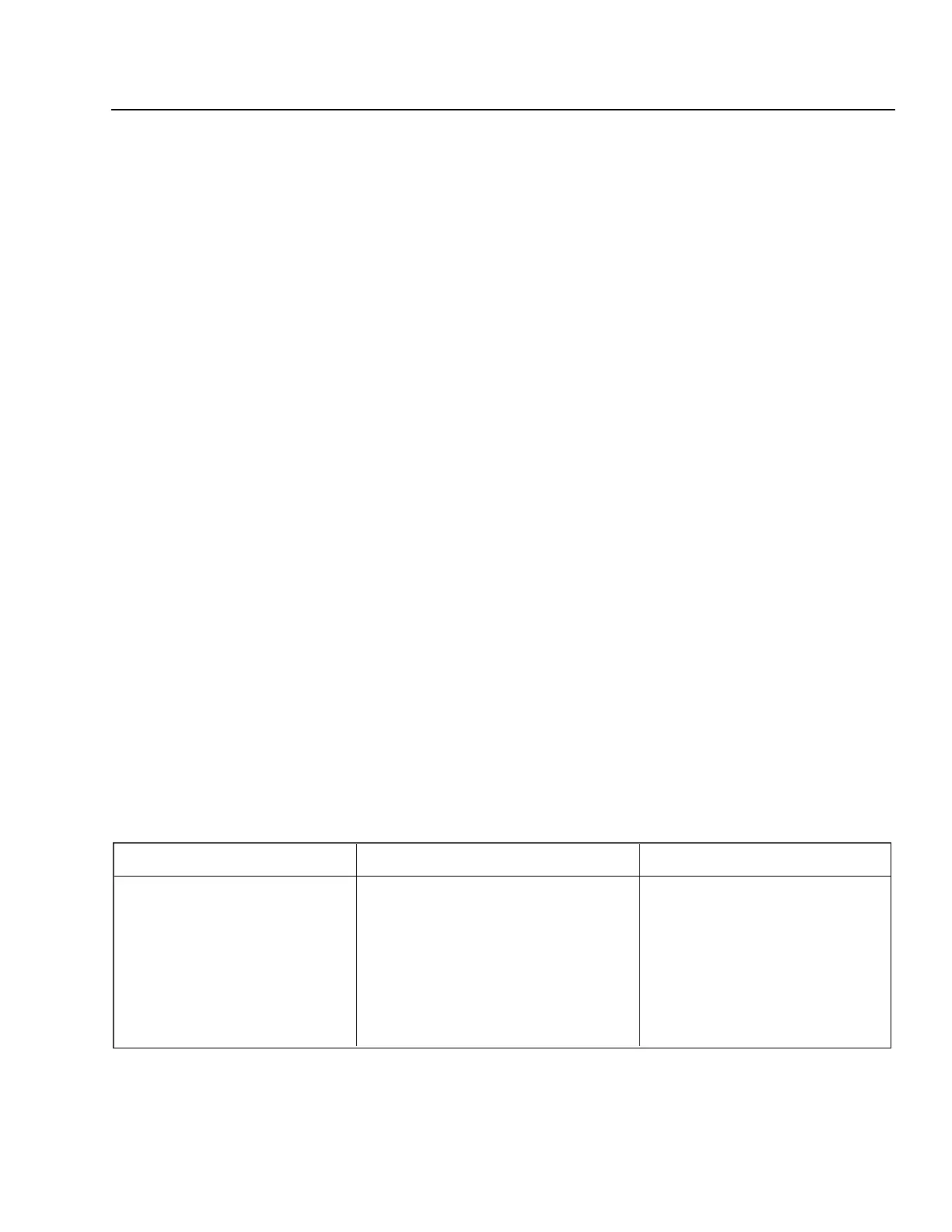

CHART 3504. PORTABLE OXYGEN SYSTEM COMPONENT LIMITS

— END —

PARTS INSPECTION OVERHAUL

Regulator 300 Flight Hrs. 5 Years

Pressure Gauge 300 Flight Hrs. 5 Years

Outlets 300 Flight Hrs. 5 Years

Recharge Valve Each Use Replace Every 3 Yrs.

Masks Each Use Replace as Necessary

PA - 4 4 - 1 8 0 / 1 8 0 T

AIRPLANE MAINTENANCE MANUAL

3 5 - 1 2 - 0 5

Page 35-18

Revised: May 15, 1989

2K2

PIPER AIRCRAFT

Loading...

Loading...