TROUBLESHOOTING PRESSURE GAUGE.

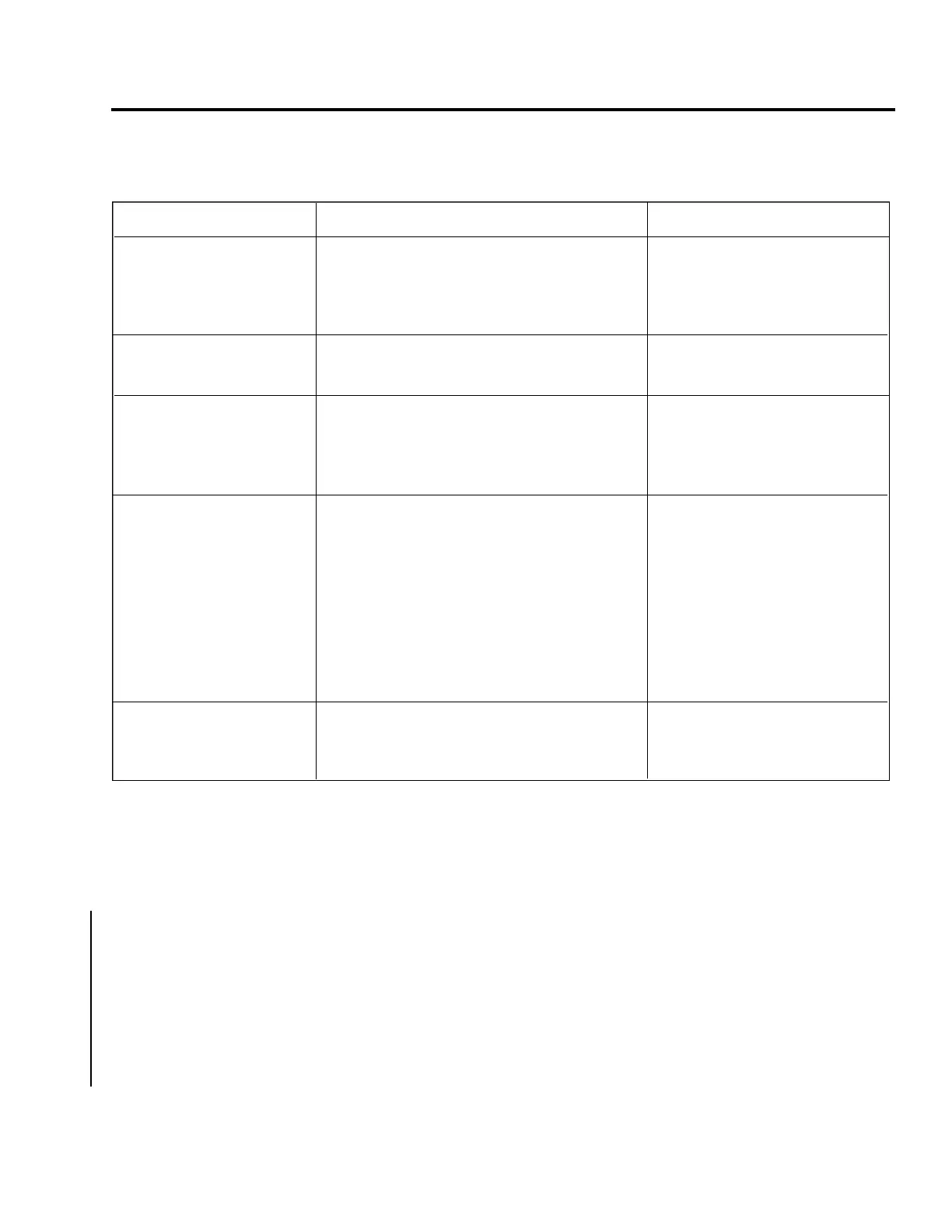

CHART 7902. OIL PRESSURE GAUGE

REMOVAL AND REPLACEMENT.

Refer to the General sectrion of Chapter 77 for Removal of Cluster Mounted Instruments.

OIL PRESSURE GAUGE CALIBRATION. (PA-44-180 S/N 44-95001 AND UP)

A calibration chart has been included for use in verifing that the suspected faulty gauge is within tolerance.

Actual recalibration of the gauge must be performed by the manufacturer or an approved instrument repair

facility.

1. With the instrument installed in the aircraft, the aircrafts’ power connected (14 VDC) and the ground

connected.

2. Remove the connection to the terminal marked SEND and connect a specified amount of resistance as

indicated on the chart, by use of a fixed resistor or a test unit capable of simulating the resistance indicated

on the chart (Power Resistor Decade Box).

Trouble Cause Remedy

Excessive error at zero. Pointer loose on shaft. Repalce instrument.

Overpressure or seasoning

of burdon tube.

Excessive scale error. Improper calibration Replace instrument.

adjustment.

Excessive pointer Air in line or rough engine Disconnect line and fill

oscillation. relief. with light oil. Check for

leaks. If trouble persists,

clean and adjust relief valve.

Sluggish operation of Engine relief valve open. Clean and check.

pointer or pressure fails

to build up.

Line restriction to Clean and check.

instrument.

Loss of oil in engine or Shut down engine.

other engine failure.

NOTE

Gauge will take longer to indicate in cold weather.

PA - 4 4 - 1 8 0 / 1 8 0 T

AIRPLANE MAINTENANCE MANUAL

7 9 - 3 2 - 0 2

Page 79-03

Revised: May 15, 1989

3I5

PIPER AIRCRAFT

Loading...

Loading...