Pleiger Elektronik

GmbH & Co. KG

Page: 26 Manual for 362MC Edition: 6/2007 Subject to modifications

6.1.3 Explanatory note on the Reset function for the controller

Param, ROM and RAM errors can only be acknowledged by resetting the controller, after which the

system monitoring process is repeated.

6.1.4 Explanatory note on Watchdog error

The 362MC incorporates a programme run monitoring function. The correctly running controller

programme regularly resets a watchdog timer. Should deviations occur during execution of the

programme, e.g. as a result of major external EMC disturbances, this resetting pulse will not be

transmitted for the timer. The watchdog timer will then initiate a programme restart. During the restart,

the cause Watchdog error is displayed. The controller programme is not stopped. This error is to be

acknowledged by pressing the Exit button, in the same manner as other error messages.

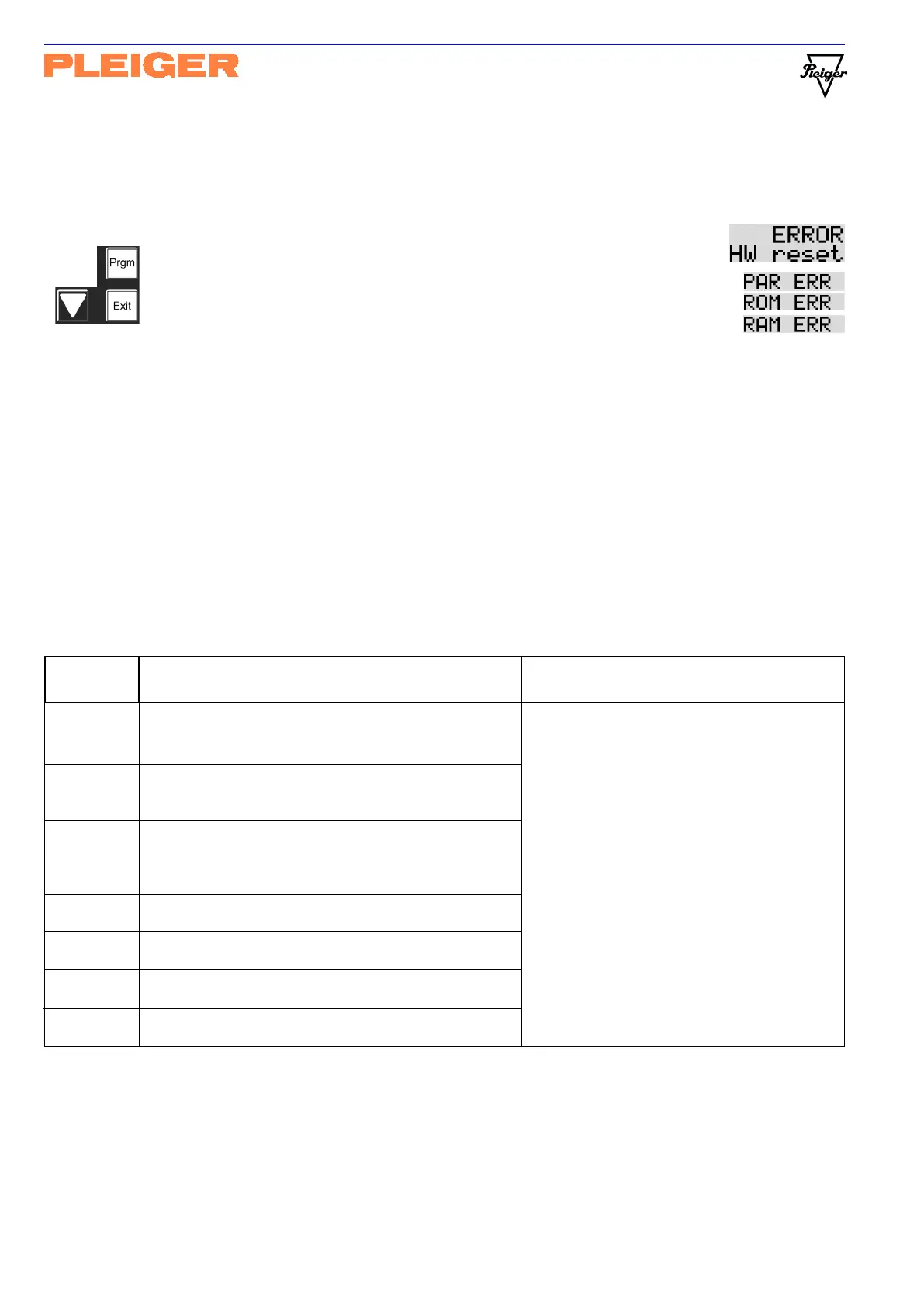

6.2 Sensor monitoring functions

The 362MC continuously checks the measured-value inputs for interruptions, short-circuits or other

deviations from the measuring range in the background during normal running of the controller

programme. As a general principle, only those errors are monitored which could actually disturb

operations on the basis of the currently parameterised functions.

Unused inputs and inputs only employed for display purpose are not monitored.

The following table provides an overview of the various error messages.

Error

display

ERRORERROR

ERRORERROR

ERROR

1.PT >11.PT >1

1.PT >11.PT >1

1.PT >1

1 >20mA1 >20mA

1 >20mA1 >20mA

1 >20mA

ERRORERROR

ERRORERROR

ERROR

1.PT <01.PT <0

1.PT <01.PT <0

1.PT <0

1 < 4mA1 < 4mA

1 < 4mA1 < 4mA

1 < 4mA

ERRORERROR

ERRORERROR

ERROR

2.PT >12.PT >1

2.PT >12.PT >1

2.PT >1

ERRORERROR

ERRORERROR

ERROR

2.PT <02.PT <0

2.PT <02.PT <0

2.PT <0

ERRORERROR

ERRORERROR

ERROR

Lin >1Lin >1

Lin >1Lin >1

Lin >1

ERRORERROR

ERRORERROR

ERROR

Lin <0Lin <0

Lin <0Lin <0

Lin <0

ERRORERROR

ERRORERROR

ERROR

Resist>1Resist>1

Resist>1Resist>1

Resist>1

ERRORERROR

ERRORERROR

ERROR

Resist<0Resist<0

Resist<0Resist<0

Resist<0

Monitoring function

for analogue inputs

The 1

st

PT100 input has a measured value

> measuring range (standard > 200°C, opt. > 500°C)

or > 20mA (optional > 100%).

The 1

st

PT100 input has a measured value

< measuring range (standard < 0°C)

or < 4mA (optional < 0%).

The 2

nd

PT100 input has a measured value

> measuring range (standard > 200°C).

The 2

nd

PT100 input has a measured value

< measuring range (standard < 0°C).

The 3

rd

analogue input has a measured value

> measuring range (standard > 20mA, opt. > 5V/10V).

The 3

rd

analogue input has a measured value

< measuring range (standard < 0(4)mA, opt. > 0V).

The resistance input has a measured value

> calibrated range (> Rmax).

The resistance input has a measured value

< calibrated range (< Rmin).

Additional measures

If the input to which the error message

relates is in use as

an actual-value input,

a setpoint input,

a trend input or

a disturbance input,

the controller programme will be stopped and

an alarm will be triggered.

The sensor and the connection cabling are to

be checked; an wire breakage, short-circuiting

or sensor defects are the most common causes

of these errors.

Beyond this, the measuring input of the

controller may be defective.This is to be checked

with a PT100 simulator or current source, for

example.

After error acknowledge, the test is repeated.

""

""

"

Errors at important inputs will lead to the controller programme being stopped and

initiation of an alarm, as safe and reliable operation of the controlled system is not

longer ensured. Please do not acknowledge the error message until the cause of

the error has been eradicated.

""

""

"

An error which does not recur immediately after being acknowledged indicates

a major EMC disturbance. Make a note of such errors. Should the error recur

frequently, the cause of the error is to be eradicated.

Controller reset These buttons are to be pressed simultaneously. The hardware reset

will be displayed. This display is to be acknowledged by pressing the

Exit button. At Programme start after reset these error messages

show any multiple errors corresponding to the errors which were

displayed briefly during the system monitoring process.

Loading...

Loading...