Pleiger Elektronik

GmbH & Co. KG

Page: 42 Manual for 362MC Edition: 6/2007 Subject to modifications

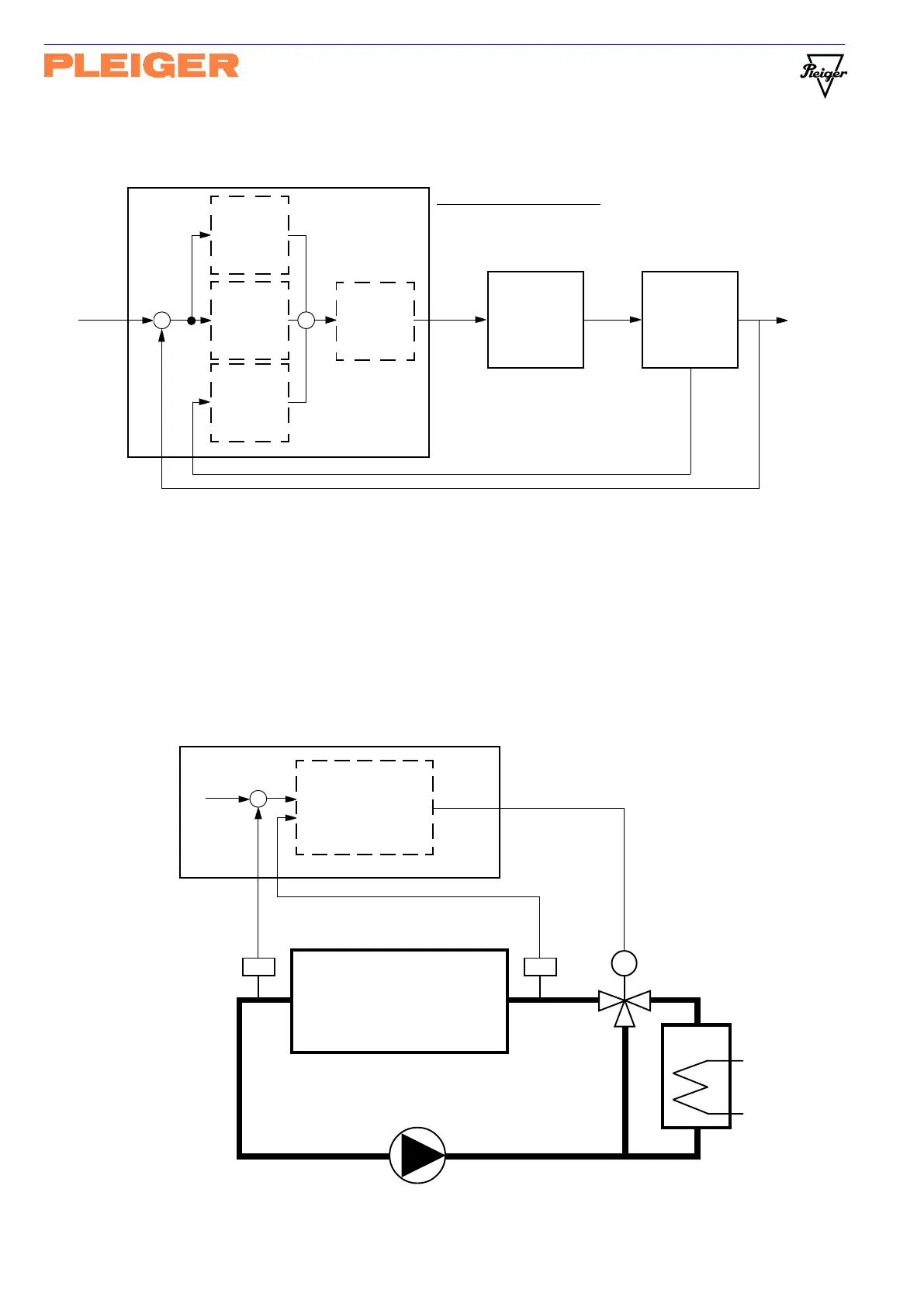

D2-Anteil bei Tendenzaufschaltung

Parameterisation

As in the case of the standard controller, the D component for the controller with activated trend

compensation is also set via the control parameters Tv and Vd.

See also Controller parameters menu (5.5)

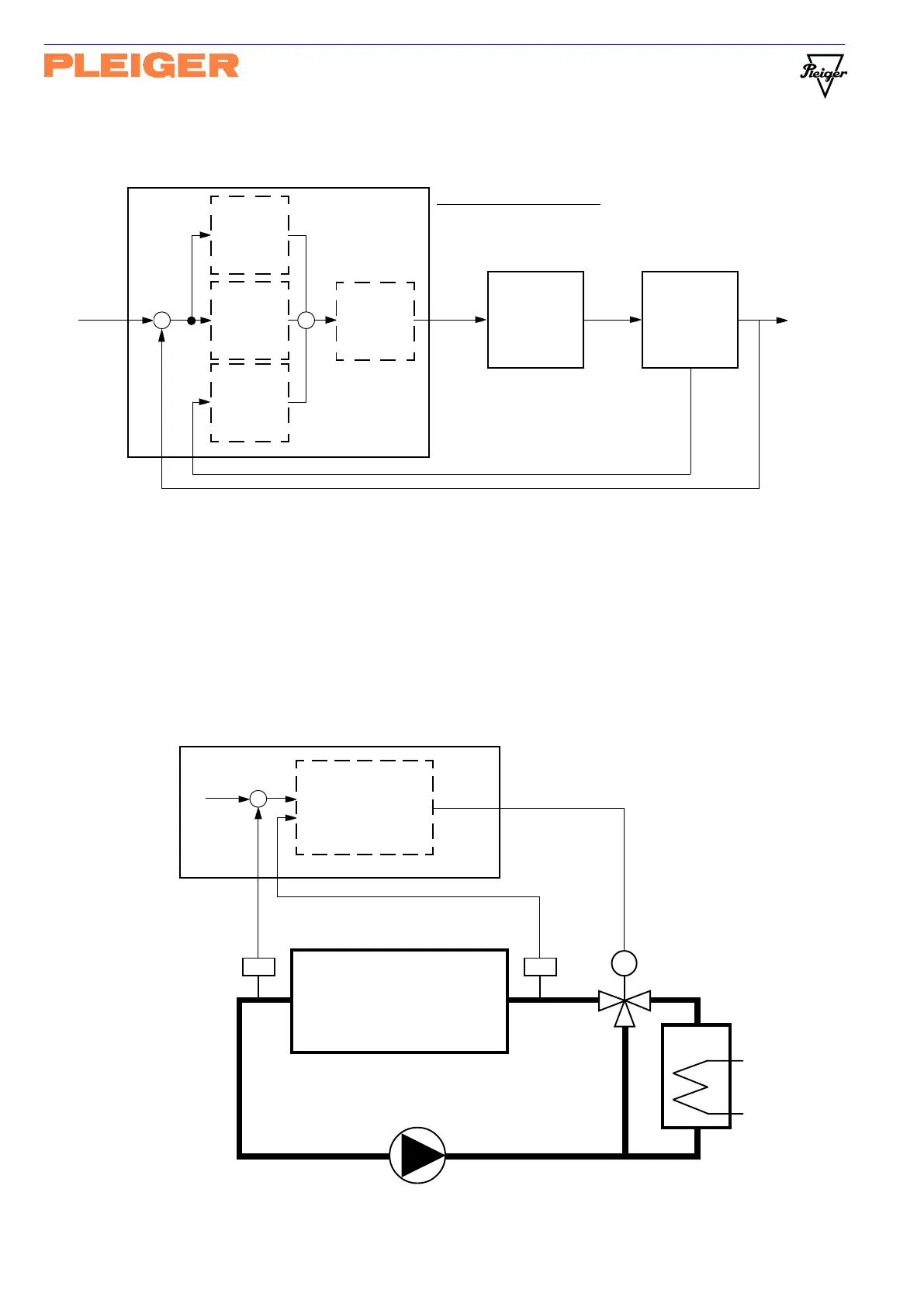

Example

The circuit diagram below shows a typical example of the use of the special trend compensation

function. Here, an inlet temperature sensor (T

IN

) has been added to the outlet temperature control (T

OUT

)

of a main engine. The effects of the dead time between the outlet temperature sensor and the mixing

valve are reduced substantially by means of the special trend compensation function

(parameter Trend = PT100-2).

Cooler

Main engine

M

T

OUT

PT100

Tend D

3-Point

step controller

T

IN

PT100

PT100-1 PT100-2

TTTT

ActV X

Out+Y

1Relay

362MC

Setp W

-

362MC with trend compensation

(Structure with D2) in input menu:

ActValX = PT100-1

Tend = PT100-2

Tend D

ActV X

Switching

output

or

Analogue

output

Setp W dx

-

Out+Y

Out%Y

I-

controller

P-

controller

Actuator Controlled

system

Feed Y

D2-

controller

Loading...

Loading...